Assistive technology (AT) is a term for assistive, adaptive, and rehabilitative devices for people with disabilities and the elderly. Disabled people often have difficulty performing activities of daily living (ADLs) independently, or even with assistance. ADLs are self-care activities that include toileting, mobility (ambulation), eating, bathing, dressing, grooming, and personal device care. Assistive technology can ameliorate the effects of disabilities that limit the ability to perform ADLs. Assistive technology promotes greater independence by enabling people to perform tasks they were formerly unable to accomplish, or had great difficulty accomplishing, by providing enhancements to, or changing methods of interacting with, the technology needed to accomplish such tasks. For example, wheelchairs provide independent mobility for those who cannot walk, while assistive eating devices can enable people who cannot feed themselves to do so. Due to assistive technology, disabled people have an opportunity of a more positive and easygoing lifestyle, with an increase in "social participation", "security and control", and a greater chance to "reduce institutional costs without significantly increasing household expenses." In schools, assistive technology can be critical in allowing students with disabilities to access the general education curriculum. Students who experience challenges writing or keyboarding, for example, can use voice recognition software instead. Assistive technologies assist people who are recovering from strokes and people who have sustained injuries that affect their daily tasks.

Functional electrical stimulation (FES) is a technique that uses low-energy electrical pulses to artificially generate body movements in individuals who have been paralyzed due to injury to the central nervous system. More specifically, FES can be used to generate muscle contraction in otherwise paralyzed limbs to produce functions such as grasping, walking, bladder voiding and standing. This technology was originally used to develop neuroprostheses that were implemented to permanently substitute impaired functions in individuals with spinal cord injury (SCI), head injury, stroke and other neurological disorders. In other words, a person would use the device each time he or she wanted to generate a desired function. FES is sometimes also referred to as neuromuscular electrical stimulation (NMES).

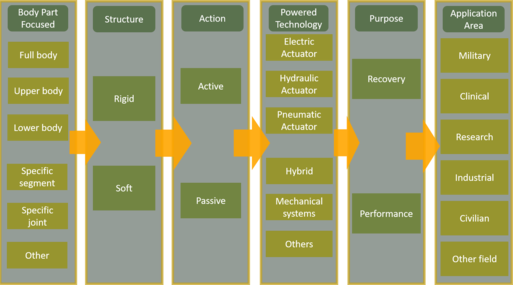

The Hybrid Assistive Limb is a powered, soft-bodied exoskeleton suit developed by Japan's Tsukuba University and the robotics company Cyberdyne. It is designed to support and expand the physical capabilities of its users, particularly people with physical disabilities. There are two primary versions of the system: HAL 3, which only provides leg function, and HAL 5, which is a full-body exoskeleton for the arms, legs, and torso.

Bio-mechatronics is an applied interdisciplinary science that aims to integrate biology and mechatronics. It also encompasses the fields of robotics and neuroscience. Biomechatronic devices cover a wide range of applications, from developing prosthetic limbs to engineering solutions concerning respiration, vision, and the cardiovascular system.

The Shirley Ryan AbilityLab, formerly the Rehabilitation Institute of Chicago (RIC), is a not-for-profit physical medicine and rehabilitation research hospital based in Chicago, Illinois. Founded in 1954, the AbilityLab is designed for patient care, education, and research in physical medicine and rehabilitation (PM&R). The AbilityLab specializes in rehabilitation for adults and children with the most severe, complex conditions ranging from traumatic brain and spinal cord injury to stroke, amputation and cancer-related impairment. Affiliated with Northwestern University, the hospital is located on Northwestern’s Chicago campus and partners on research and medical efforts.

Human Universal Load Carrier, or HULC, is an un-tethered, hydraulic-powered anthropomorphic exoskeleton developed by Professor H. Kazerooni and his team at Ekso Bionics. It is intended to help soldiers in combat carry a load of up to 200 pounds at a top speed of 10 miles per hour for extended periods of time. After being under development at Berkeley Robotics and Human Engineering Laboratory since 2000, the system was announced publicly at the AUSA Winter Symposium on February 26, 2009, when an exclusive licensing agreement was reached with Lockheed Martin. Although the exoskeleton is powered and can be used, the project was a failure as it hindered certain movements and actually increased strain on muscles, going directly against what a powered exoskeleton is supposed to do.

ReWalk is a commercial bionic walking assistance system that uses powered leg attachments to enable paraplegics to stand upright, walk and climb stairs. The system is powered by a backpack battery, and is controlled by a simple wrist-mounted remote which detects and enhances the user's movements. Designed in Yokneam, Israel, by Amit Goffer, the ReWalk is marketed by Lifeward Ltd., and is priced at approximately US$85,000 per unit.

SoldierStrong is a Stamford, Connecticut based 501(c)(3) charitable organization whose mission is to help America's military veterans take their next steps forward in life after service.

Homayoon Kazerooni is an Iranian-born American roboticist, mechanical engineering, and professor. He serves as a professor of mechanical engineering, and the director of the Berkeley Robotics and Human Engineering Laboratory at the University of California, Berkeley. Kazerooni is also the co-founder of Ekso Bionics and SuitX. As a noted authority on robotics, he is frequently profiled and quoted in the media.

Ekso Bionics Holdings Inc. is a company that develops and manufactures powered exoskeleton bionic devices that can be strapped on as wearable robots to enhance the strength, mobility, and endurance of industrial workers and people experiencing paralysis and mobility issues after a brain injury, stroke, multiple sclerosis (MS) or spinal cord injury. They enable individuals with any amount of lower extremity weakness, including those who are paralyzed, to stand up and walk.

Berkeley Robotics and Human Engineering Laboratory is managed and operated by University of California, Berkeley. The lab conducts scientific research on the design and control of a class of robotic systems worn or operated by humans to increase human mechanical strength.

When treating a person with a spinal cord injury, repairing the damage created by injury is the ultimate goal. By using a variety of treatments, greater improvements are achieved, and, therefore, treatment should not be limited to one method. Furthermore, increasing activity will increase his/her chances of recovery.

The Vanderbilt exoskeleton, marketed as Indego, is a powered exoskeleton designed by the Center for Intelligent Mechatronics at Vanderbilt University in the U.S. state of Tennessee. It is intended to assist paraplegics, stroke victims and other paralyzed or semi-paralyzed people to walk independently. Motion and control technologies manufacturer Parker Hannifin is funding further development, and plans to release the first commercial version of the exoskeleton in 2015.

Neuromechanics of orthoses refers to how the human body interacts with orthoses. Millions of people in the U.S. suffer from stroke, multiple sclerosis, postpolio, spinal cord injuries, or various other ailments that benefit from the use of orthoses. Insofar as active orthoses and powered exoskeletons are concerned, the technology to build these devices is improving rapidly, but little research has been done on the human side of these human-machine interfaces.

Cybathlon, a project of ETH Zurich, acts as a platform that challenges teams from all over the world to develop assistive technologies suitable for everyday use with and for people with disabilities. The driving force behind CYBATHLON is international competitions and events, in which teams consisting of technology developers from universities, companies or NGOs and a person with disabilities (pilot) tackle unsolved everyday tasks with their latest assistive technologies. Besides the actual competition, the Cybathlon offers a benchmarking platform to drive forward research on assistance systems for dealing with daily-life challenges, and to promote dialogue with the public for the inclusion of people with disabilities in society. The involvement of the pilot is considered essential both to the competition and in the development process, to ensure that the perspective and needs of end users are considered and addressed.

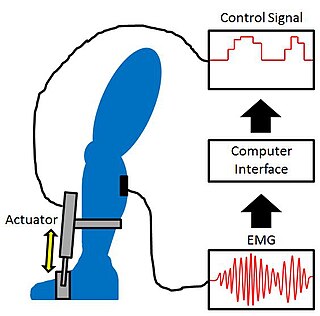

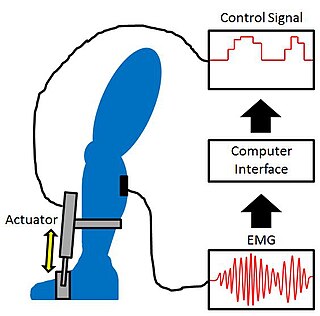

Proportional myoelectric control can be used to activate robotic lower limb exoskeletons. A proportional myoelectric control system utilizes a microcontroller or computer that inputs electromyography (EMG) signals from sensors on the leg muscle(s) and then activates the corresponding joint actuator(s) proportionally to the EMG signal.

Spinal cord injury research seeks new ways to cure or treat spinal cord injury in order to lessen the debilitating effects of the injury in the short or long term. There is no cure for SCI, and current treatments are mostly focused on spinal cord injury rehabilitation and management of the secondary effects of the condition. Two major areas of research include neuroprotection, ways to prevent damage to cells caused by biological processes that take place in the body after the injury, and neuroregeneration, regrowing or replacing damaged neural circuits.

Gail F. Forrest is an associate director of Human Performance and Engineering Research at Kessler Foundation and an associate professor in the Department of Physical Medicine & Rehabilitation at New Jersey Medical School. She has also conducted more than 20 federal, state, and national clinical trials for patients with spinal cord injury. She is also part of the research team winning the Neuromod Prize in 2022 for new collaborative work on the development of neuromodulation therapies.

A soft exoskeleton, also known as a soft wearable robot or a soft robotic exosuit, is a type of wearable robotic device designed to augment and enhance the physical abilities of the human body. Unlike traditional rigid exoskeletons, which are typically made of hard materials like metal and are worn over the user's limbs, soft exoskeletons are constructed from flexible and lightweight materials. Soft exoskeletons are designed to assist individuals with mobility impairments, aid in rehabilitation, augment human performance, and improve overall quality of life.

Kyoungchul Kong is a South Korean mechanical engineer, entrepreneur, academic, and author. He was selected as one of the Leader Scientists from the National Research Foundation of Korea in 2023. He serves as an associate professor at the Korea Advanced Institute of Science and Technology (KAIST) and is the Chief Executive Officer (CEO) of Angel Robotics.