A kiln is a thermally insulated chamber, a type of oven, that produces temperatures sufficient to complete some process, such as hardening, drying, or chemical changes. Kilns have been used for millennia to turn objects made from clay into pottery, tiles and bricks. Various industries use rotary kilns for pyroprocessing and to transform many other materials.

A boiler is a closed vessel in which fluid is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking, and sanitation.

A furnace, referred to as a heater or boiler in British English, is an appliance used to generate heat for all or part of a building. Furnaces are mostly used as a major component of a central heating system. Furnaces are permanently installed to provide heat to an interior space through intermediary fluid movement, which may be air, steam, or hot water. Heating appliances that use steam or hot water as the fluid are normally referred to as a residential steam boilers or residential hot water boilers. The most common fuel source for modern furnaces in North America and much of Europe is natural gas; other common fuel sources include LPG, fuel oil, wood and in rare cases coal. In some areas electrical resistance heating is used, especially where the cost of electricity is low or the primary purpose is for air conditioning. Modern high-efficiency furnaces can be up to 98% efficient and operate without a chimney, with a typical gas furnace being about 80% efficient. Waste gas and heat are mechanically ventilated through either metal flue pipes or polyvinyl chloride (PVC) pipes that can be vented through the side or roof of the structure. Fuel efficiency in a gas furnace is measured in AFUE.

A barbecue grill or barbeque grill is a device that cooks food by applying heat from below. There are several varieties of grills, with most falling into one of three categories: gas-fueled, charcoal, or electric. There is debate over which method yields superior results.

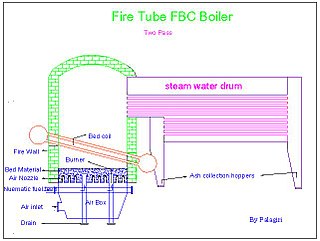

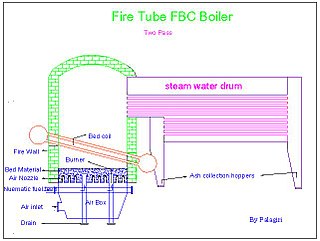

Fluidized bed combustion (FBC) is a combustion technology used to burn solid fuels.

An oven is a tool which is used to expose materials to a hot environment. Ovens contain a hollow chamber and provide a means of heating the chamber in a controlled way. In use since antiquity, they have been used to accomplish a wide variety of tasks requiring controlled heating. Because they are used for a variety of purposes, there are many different types of ovens. These types differ depending on their intended purpose and based upon how they generate heat.

A stove or range is a device that generates heat inside or on top of the device, for local heating or cooking. Stoves can be powered with many fuels, such as electricity, natural gas, gasoline, wood, and coal.

A central heating system provides warmth to a number of spaces within a building from one main source of heat. It is a component of heating, ventilation, and air conditioning systems, which can both cool and warm interior spaces.

Pyrometallurgy is a branch of extractive metallurgy. It consists of the thermal treatment of minerals and metallurgical ores and concentrates to bring about physical and chemical transformations in the materials to enable recovery of valuable metals. Pyrometallurgical treatment may produce products able to be sold such as pure metals, or intermediate compounds or alloys, suitable as feed for further processing. Examples of elements extracted by pyrometallurgical processes include the oxides of less reactive elements like iron, copper, zinc, chromium, tin, and manganese.

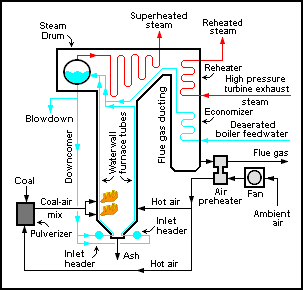

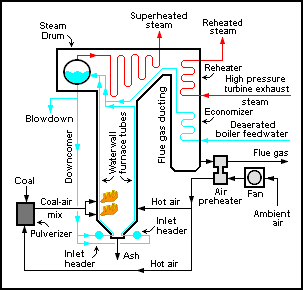

An air preheater is any device designed to heat air before another process, with the primary objective of increasing the thermal efficiency of the process. They may be used alone or to replace a recuperative heat system or to replace a steam coil.

A pulverized coal-fired boiler is an industrial or utility boiler that generates thermal energy by burning pulverized coal that is blown into the firebox.

Ceramic glaze, or simply glaze, is a glassy coating on ceramics. It is used for decoration, to ensure the item is impermeable to liquids and to minimise the adherence of pollutants.

A crematorium or crematory is a venue for the cremation of the dead. Modern crematoria contain at least one cremator, a purpose-built furnace. In some countries a crematorium can also be a venue for open-air cremation. In many countries, crematoria contain facilities for funeral ceremonies, such as a chapel. Some crematoria also incorporate a columbarium, a place for interring cremation ashes.

Overglaze decoration, overglaze enamelling, or on-glaze decoration, is a method of decorating pottery, most often porcelain, where the coloured decoration is applied on top of the already fired and glazed surface, and then fixed in a second firing at a relatively low temperature, often in a muffle kiln. It is often described as producing "enamelled" decoration. The colours fuse on to the glaze, so the decoration becomes durable. This decorative firing is usually done at a lower temperature which allows for a more varied and vivid palette of colours, using pigments which will not colour correctly at the high temperature necessary to fire the porcelain body. Historically, a relatively narrow range of colours could be achieved with underglaze decoration, where the coloured pattern is applied before glazing, notably the cobalt blue of blue and white porcelain.

This is a list of pottery and ceramic terms.

Pellet heating is a heating system in which wood pellets are combusted. Other pelletized fuels such as straw pellets are used occasionally. Today's central heating system which run on wood pellets as a renewable energy source are comparable in operation and maintenance of oil and gas heating systems.

An industrial furnace, also known as a direct heater or a direct fired heater, is a device used to provide heat for an industrial process, typically higher than 400 degrees Celsius. They are used to provide heat for a process or can serve as reactor which provides heats of reaction. Furnace designs vary as to its function, heating duty, type of fuel and method of introducing combustion air. Heat is generated by an industrial furnace by mixing fuel with air or oxygen, or from electrical energy. The residual heat will exit the furnace as flue gas. These are designed as per international codes and standards the most common of which are ISO 13705 / American Petroleum Institute (API) Standard 560. Types of industrial furnaces include batch ovens, metallurgical furnaces, vacuum furnaces, and solar furnaces. Industrial furnaces are used in applications such as chemical reactions, cremation, oil refining, and glasswork.

A glass melting furnace is designed to melt raw materials into glass.

A metallurgical furnace, often simply referred to as a furnace when the context is known, is an industrial furnace used to heat, melt, or otherwise process metals. Furnaces have been a central piece of equipment throughout the history of metallurgy; processing metals with heat is even its own engineering specialty known as pyrometallurgy.