Related Research Articles

Automotive engineering, along with aerospace engineering and naval architecture, is a branch of vehicle engineering, incorporating elements of mechanical, electrical, electronic, software, and safety engineering as applied to the design, manufacture and operation of motorcycles, automobiles, and trucks and their respective engineering subsystems. It also includes modification of vehicles. Manufacturing domain deals with the creation and assembling the whole parts of automobiles is also included in it. The automotive engineering field is research intensive and involves direct application of mathematical models and formulas. The study of automotive engineering is to design, develop, fabricate, and test vehicles or vehicle components from the concept stage to production stage. Production, development, and manufacturing are the three major functions in this field.

Packaging is the science, art and technology of enclosing or protecting products for distribution, storage, sale, and use. Packaging also refers to the process of designing, evaluating, and producing packages. Packaging can be described as a coordinated system of preparing goods for transport, warehousing, logistics, sale, and end use. Packaging contains, protects, preserves, transports, informs, and sells. In many countries it is fully integrated into government, business, institutional, industrial, and personal use.

A contract packager, or copacker, is a company that packages products for their clients. The packaging and labeling services can be used for many types of products including foods, pharmaceuticals, household products, and industrial products.

The American Meat Institute (AMI) was the oldest and largest trade association representing the U.S. meat and poultry industry. In 2015, it was merged into the North American Meat Institute (NAMI).

Food safety is used as a scientific method/discipline describing handling, preparation, and storage of food in ways that prevent food-borne illness. The occurrence of two or more cases of a similar illness resulting from the ingestion of a common food is known as a food-borne disease outbreak. This includes a number of routines that should be followed to avoid potential health hazards. In this way, food safety often overlaps with food defense to prevent harm to consumers. The tracks within this line of thought are safety between industry and the market and then between the market and the consumer. In considering industry to market practices, food safety considerations include the origins of food including the practices relating to food labeling, food hygiene, food additives and pesticide residues, as well as policies on biotechnology and food and guidelines for the management of governmental import and export inspection and certification systems for foods. In considering market to consumer practices, the usual thought is that food ought to be safe in the market and the concern is safe delivery and preparation of the food for the consumer.

The Center for Food Safety and Applied Nutrition is the branch of the United States Food and Drug Administration (FDA) that regulates food, dietary supplements, cosmetics, drugs, biologics, medical devices, and radiological products.

The Construction Products Association (CPA) is a UK construction industry trade association. It represents and champions manufacturers and suppliers of construction products. As well as representing some of the largest construction product manufacturers in the UK, the CPA also acts as the 'umbrella' trade organisation for dozens of sector and product-specific trade associations, which themselves represent thousands of companies, mostly SMEs and family-run businesses.

NPES, The Association for Suppliers of Printing, Publishing and Converting Technologies, is a trade association based in the United States representing more than four hundred companies that manufacture and distribute equipment, systems, software, and supplies used in printing, publishing, and converting.

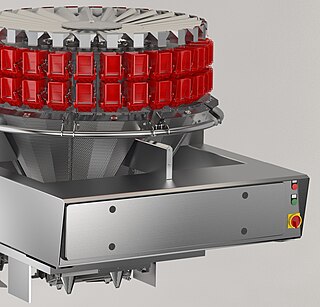

A multihead weigher is a fast, accurate and reliable weighing machine, used in packing both food and non-food products.

Produce traceability makes it possible to track produce from its point of origin to a retail location where it is purchased by consumers.

Packaging Machinery Technology (ISSN-1556-1658) was a trade publication and web site owned by PMMI for packaging and packaging machinery manufacturers and packaging engineers in the United States and Canada.

PackML is an industry technical standard for the control of packaging machines, as an aspect of industrial automation.

The Organization for Machine Automation and Control (OMAC) is a global organization that supports the machine automation and operational needs of manufacturing. OMAC was formed by General Motors in the 1980s under the name Open Modular Architecture Controls to address the problem of each machine having different controls and/or software implementations. In 2008, OMAC changed its name to the Organization for Machine Automation and Control to better reflect the broader mission and scope of its on-going activities.

Anuga FoodTec is a trade fair for the food and beverage industry. It covers aspects of food production including process technology, filling and packaging technology, packaging materials, ingredients and food safety, and food production. It is structured into eight product segments: food processing, food packaging, safety and analytics, digitalisation, automation, intralogistics, environment and energy, science and pioneering.

Intralox, headquartered in the New Orleans, Louisiana, suburb of Harahan is a manufacturer of conveyor belts. Intralox specializes in modular plastic conveyor belts and related services and equipment.

UFP Technologies, Inc., founded in 1963 and based in Newburyport, Massachusetts, is a designer and custom manufacturer of components, sub-assemblies, products and packaging utilizing highly specialized foams, films, and plastics primarily for the medical market.

Packaging machinery is used throughout all packaging operations, involving primary packages to distribution packs. This includes many packaging processes: fabrication, cleaning, filling, sealing, combining, labeling, overwrapping, palletizing.

Predictive engineering analytics (PEA) is a development approach for the manufacturing industry that helps with the design of complex products. It concerns the introduction of new software tools, the integration between those, and a refinement of simulation and testing processes to improve collaboration between analysis teams that handle different applications. This is combined with intelligent reporting and data analytics. The objective is to let simulation drive the design, to predict product behavior rather than to react on issues which may arise, and to install a process that lets design continue after product delivery.

The distribution of medications has special drug safety and security considerations. Some drugs require cold chain management in their distribution.

Fabricators & Manufacturers Association, International (FMA) is a 501(c)3 nonprofit professional association serving both company and individual members in the metal processing, forming, and fabricating industries.

References

- ↑ "About PMMI, The Association for Packaging and Processing Technologies". www.pmmi.org. Retrieved 2020-01-20.

- ↑ Redner, Boyd (1990), A History of the Packaging Machinery Manufacturers Institute, p. 5

- ↑ PMMI Board of Directors Meeting Minutes, 1942

- ↑ "Triple the size in 20 years". Packaging World. 2015-07-06. Retrieved 2020-01-20.

- ↑ "PMMI | The Association for Packaging and Processing Technologies". www.pmmi.org. Retrieved 2020-01-20.

- ↑ Pack Expo and Anuga FoodTec form strategic partnership

- ↑ "Manufacturing Workforce Development Playbook" (PDF). National Institute of Standards and Technology. Retrieved 30 April 2018.

- ↑ Bellm, David. "Packaging machinery: PMMI U launches mechatronics certificate test". Packaging Digest. Retrieved 30 April 2018.

- ↑ "National Product Liability Act". Congress.gov. US Government. Retrieved 15 December 2017.

- ↑ Riley, Sean. "Setting a standard". Packaging World. Retrieved 15 December 2017.