| |

| Names | |

|---|---|

| IUPAC name Iron boride | |

| Other names Diiron boride, Fe2B | |

| Identifiers | |

| |

3D model (JSmol) |

|

| ChemSpider | |

| EC Number |

|

PubChem CID | |

CompTox Dashboard (EPA) |

|

| |

| |

| Properties | |

| Fe2B | |

| Molar mass | 122.501 g/mol [1] |

| Appearance | refractory solid |

| Density | 7.3 g/cm3 [1] |

| Melting point | 1,389 °C (2,532 °F; 1,662 K) [1] |

| insoluble | |

| Structure [2] | |

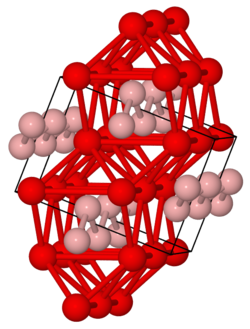

| Tetragonal, tI12 | |

| I4/mc, No. 140 | |

a = 0.511 nm, b = 0.511 nm, c = 0.4249 nm | |

Formula units (Z) | 4 |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| |

| Names | |

|---|---|

| IUPAC name Iron boride | |

| Other names Iron monoboride, FeB | |

| Identifiers | |

| |

3D model (JSmol) |

|

| ChemSpider | |

| EC Number |

|

PubChem CID |

|

| |

| |

| Properties | |

| FeB | |

| Molar mass | 66.656 [1] |

| Appearance | grey powder |

| Density | ~7 g/cm3 [1] |

| Melting point | 1,658 °C (3,016 °F; 1,931 K) [1] |

| insoluble | |

| Structure [3] | |

| Orthorhombic, oP8 | |

| Pnma, No. 62 | |

a = 0.4061 nm, b = 0.5506 nm, c = 0.2952 nm | |

Formula units (Z) | 4 |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

Iron boride refers to various inorganic compounds with the formula FexBy. [4] Two main iron borides are FeB and Fe2B. Some iron borides possess useful properties such as magnetism, electrical conductivity, corrosion resistance and extreme hardness. Some iron borides have found use as hardening coatings for iron. Iron borides have properties of ceramics such as high hardness, and properties of metal properties, such as thermal conductivity and electrical conductivity. Boride coatings on iron are superior mechanical, frictional, and anti-corrosive. [5] Iron monoboride (FeB) is a grey powder that is insoluble in water. FeB is harder than Fe2B, but is more brittle and more easily fractured upon impact.