A locomotive is a rail transport vehicle that provides the motive power for a train. If a locomotive is capable of carrying a payload, it is usually rather referred to as a multiple unit, motor coach, railcar or power car; the use of these self-propelled vehicles is increasingly common for passenger trains, but rare for freight trains.

A diesel locomotive is a type of railway locomotive in which the power source is a diesel engine. Several types of diesel locomotives have been developed, differing mainly in the means by which mechanical power is conveyed to the driving wheels. The most common are diesel–electric locomotives and diesel–hydraulic.

A stationary engine is an engine whose framework does not move. They are used to drive immobile equipment, such as pumps, generators, mills or factory machinery, or cable cars. The term usually refers to large immobile reciprocating engines, principally stationary steam engines and, to some extent, stationary internal combustion engines. Other large immobile power sources, such as steam turbines, gas turbines, and large electric motors, are categorized separately.

British Rail 18000 was a prototype mainline gas turbine–electric locomotive built for British Railways in 1949 by Brown, Boveri & Cie. An earlier gas-turbine locomotive, 18100, had been ordered from Metropolitan-Vickers by the Great Western Railway but construction was delayed due to World War II; a second, 18000, was thus ordered from Switzerland in 1946. It spent its working life on the Western Region of British Railways, operating express passenger services from Paddington station, London.

The following lists events that happened during 1923 in South Africa.

A gas turbine locomotive is a type of railway locomotive in which the prime mover is a gas turbine. Several types of gas turbine locomotive have been developed, differing mainly in the means by which mechanical power is conveyed to the driving wheels (drivers). A gas turbine train typically consists of two power cars, and one or more intermediate passenger cars.

British Rail 18100 was a prototype main line gas turbine–electric locomotive built for British Railways in 1951 by Metropolitan-Vickers, Manchester. It had, however, been ordered by the Great Western Railway in the 1940s, but construction was delayed due to World War II. It spent its working life on the Western Region of British Railways, operating express passenger services from Paddington station, London.

A hybrid train is a locomotive, railcar or train that uses an onboard rechargeable energy storage system (RESS), placed between the power source and the traction transmission system connected to the wheels. Since most diesel locomotives are diesel-electric, they have all the components of a series hybrid transmission except the storage battery, making this a relatively simple prospect.

A steam diesel hybrid locomotive is a railway locomotive with a piston engine which could run on either steam from a boiler or diesel fuel. Examples were built in the United Kingdom, Soviet Union and Italy but the relatively high cost of fuel oil, or failure to resolve problems caused by technical complexity, meant that the designs were not pursued.

The Union Pacific GTELs were a series of gas turbine–electric locomotives built by Alco-GE and General Electric from 1952 to 1961 and operated by Union Pacific from 1952 to 1970.

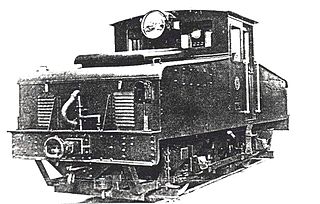

Am 4/6 1101 was the world's first gas turbine–electric locomotive. The locomotive was ordered by the Swiss Federal Railways (SBB-CFF-FFS) from the Swiss Locomotive and Machine Works (SLM) and Brown, Boveri & Cie (BBC) in 1939. The locomotive was delivered in 1941 and was in use on railroads in Switzerland, France and Germany until 1954.

The South African Railways Class 26 4-8-4 of 1981, popularly known as the Red Devil, is a 4-8-4 steam locomotive which was rebuilt from a Class 25NC locomotive by mechanical engineer David Wardale from England while in the employ of the South African Railways. The rebuilding took place at the Salt River Works in Cape Town and was based on the principles developed by Argentinian mechanical engineer L.D. Porta.

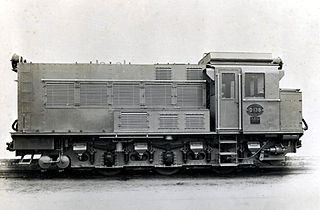

The South African Railways Class 61-000 of 1959 was a diesel-hydraulic locomotive.

The South African Railways Class 2E of 1937 was an electric locomotive.

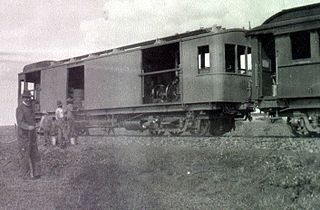

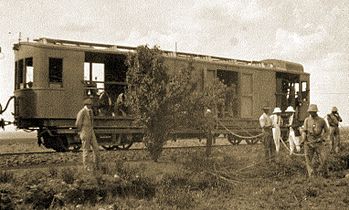

The Heilmann locomotives were a series of three experimental steam–electric locomotives produced in the 1890s for the French Chemins de fer de l'Ouest. A prototype was built in 1894 and two larger locomotives were built in 1897. These locomotives used electric transmission, much like later-popular diesel–electric locomotives and various other self-powered locomotives.

The South African Railways Class ES1 of 1924 was an electric locomotive.

The South African Railways Class DS of 1939 was a diesel-electric locomotive.

The South African Railways Class DS1 of 1939 was a diesel-electric locomotive.

Under the British and Imperial classification scheme of locomotive axle arrangements 1Co+Co1 is a classification code for a locomotive wheel arrangement of two eight-wheeled bogies with an articulated inter-bogie connection, each with three axles powered by a separate traction motor per axle and with the fourth non-powered axle in an integral leading pony truck to reduce the axle load. The similar 1Co-Co1 classification is in the same axle configuration, but without the inter-bogie connection.

An internal combustion locomotive is a type of railway locomotive that produces its pulling power using an internal combustion engine. These locomotives are fuelled by burning fossil fuels, most commonly oil or gasoline, to produce rotational power which is transmitted to the locomotive's driving wheels by various direct or indirect transmission mechanisms. The fuel is carried on the locomotive.