The Meal, Ready-to-Eat (MRE) is a self-contained individual United States military ration used by the United States Armed Forces and Department of Defense. It is intended for use by American service members in combat or field conditions where other food is not available. MREs have also been distributed to civilians as humanitarian daily rations during natural disasters and wars.

United States military ration refers to the military rations provided to sustain United States Armed Forces service members, including field rations and garrison rations, and the military nutrition research conducted in relation to military food. U.S. military rations are often made for quick distribution, preparation, and eating in the field and tend to have long storage times in adverse conditions due to being thickly packaged or shelf-stable.

Deicing is the process of removing snow, ice or frost from a surface. Anti-icing is the application of chemicals that not only deice but also remain on a surface and continue to delay the reformation of ice for a certain period of time, or prevent adhesion of ice to make mechanical removal easier.

A heating pad is a pad used for warming of parts of the body in order to manage pain. Localized application of heat causes the blood vessels in that area to dilate, enhancing perfusion to the targeted tissue. Types of heating pads include electrical, chemical and hot water bottles.

Humanitarian daily rations are food rations manufactured in the United States intended to be supplied to civilians and other non-military personnel in humanitarian crises. Each is intended to serve as a single person's full daily food supply, and contains somewhat over 2,200 calories (9,200 kJ). They have shelf-lives of about 3 years, and their contents are designed to be acceptable to a variety of religious and ethnic groups. The meals cost approximately one-fifth of the cost of a Meal, Ready-to-Eat (MRE), or US$4.70 in 2012. The rations were first used in Bosnia in 1993 as part of Operation Provide Promise.

A field ration is a type of prepackaged military ration designed to be easily and quickly prepared and consumed in the field, in combat, at the front line, or where eating facilities are otherwise unavailable. Field rations are primarily used by military forces, though they are also sometimes distributed to civilians as part of humanitarian aid and emergency management. They differ from garrison rations and field kitchen provisions, which are intended for where proper meals can be supplied and prepared with relative ease and safety, such as in the rear where logistics are steady and fresh food can be supplied. They are similar to, but distinct from, other purpose-designed long-lasting types of food or rations such as emergency rations, humanitarian daily rations, and camping food.

The Individual Meal Pack or IMP is one type of field ration used by the Canadian Forces. The IMP is designed so that a continuous diet provides all the nutrition needed to sustain a service member in the field. The IMP meets Canada's nutrition requirements, with the exception of calcium and folic acid, which are not significant if the consumption period of rations is less than 30 (consecutive) days. IMPs provide 1,200–1,400 calories (5.0–5.9 MJ) per meal.

Hand warmers are small, often disposable, packets that produce heat to warm cold hands. They are used throughout the world in a variety of ways, including outdoor recreation, manual labor, and homelessness.

The First Strike Ration (FSR) is a compact assault United States military ration. It is designed to be consumed on the move during the first 72 hours of conflict. It was created by the United States Army Soldier Systems Center in Natick, Massachusetts. The U.S. Army said the FSR substantially reduces weight and load and is intended to enhance a consumer's physical performance, mental acuity, and mobility.

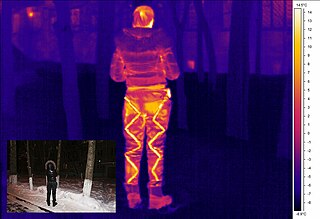

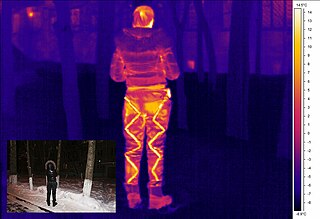

Most heated clothing is designed for cold-weather sports and activities, such as motorcycle riding, downhill skiing, diving, winter biking, and snowmobiling, trekking and for outdoor workers such as construction workers and carpenters. Since the London Olympics, heated clothing has also been used by athletes to keep their muscles warm between the warm-up and the race.

Ronald C. Wornick was an American food scientist, entrepreneur and art collector. He was best known for founding The Wornick Company, which was selected by the U.S. Department of Defense in 1979 to mass-produce Meals, Ready to Eat or MREs, a next-generation version of individual combat meals or C-Rations that brought greater menu variety and improved food storage and preparation options to servicemen in the field.

The Food Packet, Long Range Patrol was a freeze-dried dehydrated United States military ration used by the Department of Defense. Developed in 1964 and intended for wide adoption during the Vietnam War, its use was eventually limited to American special operations forces during long-range reconnaissance patrols, where bulky canned Meal, Combat, Individual (MCI) rations proved too heavy for extended missions on foot. The LRP had a cold-weather warfare equivalent, the Ration, Cold Weather (RCW).

Radiators and convectors are heat exchangers designed to transfer thermal energy from one medium to another for the purpose of space heating.

Self-heating food packaging is active packaging with the ability to heat food contents without external heat sources or power, usually using an exothermic chemical reaction. Packets can also be self-cooling. These packages are useful for military operations, during natural disasters, or whenever conventional cooking is not available. They are often used for military field rations, camping food, instant food, or other types of food intended for preparation where proper cooking facilities or methods are unavailable or less ideal.

Camping food is food brought on or designed for camping, hiking, and backpacking trips. The term also encompasses ingredients that can be used to make said foods. The primary differences relate to campers' and backpackers' special needs for foods that have appropriate cooking time, perishability, weight, and nutritional content. To address these needs, camping food is often made up of freeze-dried, dehydrated, pre-cooked, pre-prepared, or otherwise preserved foods that can last extended periods.

A catalytic heater is a flameless heater which relies on catalyzed chemical reactions to break down molecules and produce calefaction (heat). When the catalyst, fuel, and oxygen combine together, they react at a low enough temperature that a flame is not produced. This process keeps repeating itself until either oxygen or the fuel source is taken out of the equation.

A food warmer is typically a table-top device used to maintain the serving temperature of prepared food. It is used both in homes and restaurants.

The Unitized Group Ration (UGR) is a United States military ration used by the United States Armed Forces and Department of Defense (DoD). It is intended to sustain groups of American service members with access to a field kitchen, serving as a field ration and a garrison ration. It is the modern successor to several older alphabetized rations—namely the A-ration, B-ration, and T-ration—combining them under a single unified system. UGRs are designed to meet the Military Daily Recommended Allowance when averaged over a 5 to 10 day period, with each meal providing between 1,300 and 1,450 kcal.