A traction control system (TCS), is typically a secondary function of the electronic stability control (ESC) on production motor vehicles, designed to prevent loss of traction of the driven road wheels. TCS is activated when throttle input and engine power and torque transfer are mismatched to the road surface conditions.

Understeer and oversteer are vehicle dynamics terms used to describe the sensitivity of the vehicle to changes in steering angle associated with changes in lateral acceleration. This sensitivity is defined for a level road for a given steady state operating condition by the Society of Automotive Engineers (SAE) in document J670 and by the International Organization for Standardization (ISO) in document 8855. Whether the vehicle is understeer or oversteer depends on the rate of change of the understeer angle. The Understeer Angle is the amount of additional steering that must be added in any given steady-state maneuver beyond the Ackermann steer angle. The Ackermann Steer Angle is the steer angle at which the vehicle would travel about a curve when there is no lateral acceleration required.

Quattro is the trademark used by the automotive brand Audi to indicate that all-wheel drive (AWD) technologies or systems are used on specific models of its automobiles.

Automobile handling and vehicle handling are descriptions of the way a wheeled vehicle responds and reacts to the inputs of a driver, as well as how it moves along a track or road. It is commonly judged by how a vehicle performs particularly during cornering, acceleration, and braking as well as on the vehicle's directional stability when moving in steady state condition.

In automotive design, a front-engine, front-wheel-drive (FWD) layout, or FF layout, places both the internal combustion engine and driven roadwheels at the front of the vehicle.

In automotive design, an RR, or rear-engine, rear-wheel-drive layout places both the engine and drive wheels at the rear of the vehicle. In contrast to the RMR layout, the center of mass of the engine is between the rear axle and the rear bumper. Although very common in transit buses and coaches due to the elimination of the drive shaft with low-floor buses, this layout has become increasingly rare in passenger cars.

In automotive design, an RMR, or rear mid-engine, rear-wheel-drive layout is one in which the rear wheels are driven by an engine placed with its center of gravity in front of the rear axle, and thus right behind the passenger compartment. Nowadays more frequently called 'RMR', to acknowledge that certain sporty or performance focused front-engined cars are also "mid-engined", by having the main engine mass behind the front axle, RMR layout cars were previously just called MR, or mid-engine, rear-wheel-drive layout), because the nuance between distinctly front-engined vs. front mid-engined cars often remained undiscussed.

A locking differential is a mechanical component, commonly used in vehicles, designed to overcome the chief limitation of a standard open differential by essentially "locking" both wheels on an axle together as if on a common shaft. This forces both wheels to turn in unison, regardless of the traction available to either wheel individually.

A transaxle is a single mechanical device which combines the functions of an automobile's transmission, axle, and differential into one integrated assembly. It can be produced in both manual and automatic versions.

In automotive engineering, a mid-engine layout describes the placement of an automobile engine in front of the rear-wheel axles, but behind the front axle.

A swing axle is a simple type of independent suspension designed and patented by Edmund Rumpler in 1903 for the rear axle of rear wheel drive vehicles. This was a revolutionary invention in automotive suspension, allowing driven (powered) wheels to follow uneven road surfaces independently, thus enabling the vehicle's wheels to maintain better road contact and holding; plus each wheel's reduced unsprung weight means their movements have less impact on the vehicle as a whole. The first automotive application was the Rumpler Tropfenwagen, another early example was the 1923 Tatra 11 later followed by the Mercedes 130H/150H/170H, the Standard Superior, the pre-facelift Volkswagen Beetle and most of its derivatives, the Chevrolet Corvair, and the roll-over prone M151 jeep amongst others.

BMW xDrive is the marketing name for the all-wheel drive system found on various BMW models since 2003. The system uses an electronically actuated clutch-pack differential to vary the torque between the front and rear axles. Models with the DPC torque vectoring system also have a planetary gearset to overdrive an axle or rear wheel as required.

ATTESA is a four-wheel drive system used in some automobiles produced by the Japanese automaker Nissan, including some models under its luxury marque Infiniti.

Super Handling-All Wheel Drive (SH-AWD) is a full-time, fully automatic, all-wheel drive traction and handling system, which combines front-rear torque distribution control with independently regulated torque distribution to the left and right rear wheels. This way the system freely distributes the optimum amount of torque to all four wheels according to the driving conditions. The system was announced in April 2004, and was introduced in the North American market in the second generation 2005 model year Acura RL, and in Japan as the fourth generation Honda Legend.

The powertrain layout of a motorised vehicle such as a car is often defined by the location of the engine or motors and the drive wheels.

The following outline is provided as an overview of and topical guide to automobiles:

A wheelspin occurs when the force delivered to the tire tread exceeds that of available tread-to-surface friction and one or more tires lose traction. This leads the wheels to "spin" and causes the driver to lose control over the tires that no longer have grip on the road surface. Wheelspin can also be done intentionally such as in drifting or doing a burnout.

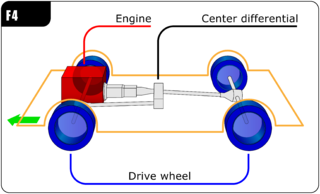

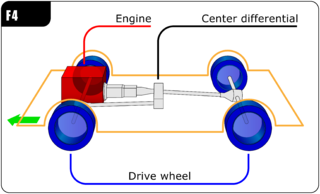

In automotive design, an F4, or front-engine, four-wheel drive (4WD) layout places the internal combustion engine at the front of the vehicle and drives all four roadwheels. This layout is typically chosen for better control on many surfaces, and is an important part of rally racing, as well as off-road driving. In terms of racing purposes, whether it be on-road or off-road, can be described as follows,

A team that pursues the Weak LS4WD architecture will minimize the development cost of the front-wheel drive system at the expense of having a larger rear powertrain. The Weak architecture produces a vehicle with a large powersplit between the front and rear powertrains, while the Strong architecture recommends a vehicle with more similar power and torque requirements for the front and rear.

Torque vectoring is a technology employed in automobile differentials that has the ability to vary the torque to each half-shaft with an electronic system; or in rail vehicles which achieve the same using individually motored wheels. This method of power transfer has recently become popular in all-wheel drive vehicles. Some newer front-wheel drive vehicles also have a basic torque vectoring differential. As technology in the automotive industry improves, more vehicles are equipped with torque vectoring differentials. This allows for the wheels to grip the road for better launch and handling.

In automotive design, dual-motor, four-wheel-drive layout is mainly used by battery electric vehicles by having two electric motors that each drives the front and rear axle, creating a four-wheel drive layout. This is made possible by the smaller size of electric motors compared to internal combustion engines (ICEs), which in addition are also accompanied by a bulky engine cooling system, allowing it to be fit more versatilely into multiple locations. The use of separate motors for the front and rear drive wheels eliminates the need of a drive shaft that is ubiquitous in four-wheel drive ICE vehicles, freeing up space for bigger battery modules, which are commonly mounted on the chassis floor between the axles.