The atmospheric engine was invented by Thomas Newcomen in 1712, and is often referred to as the Newcomen fire engine or simply as a Newcomen engine. The engine was operated by condensing steam drawn into the cylinder, thereby creating a partial vacuum which allowed the atmospheric pressure to push the piston into the cylinder. It was historically significant as the first practical device to harness steam to produce mechanical work. Newcomen engines were used throughout Britain and Europe, principally to pump water out of mines. Hundreds were constructed throughout the 18th century.

The vacuum brake is a braking system employed on trains and introduced in the mid-1860s. A variant, the automatic vacuum brake system, became almost universal in British train equipment and in countries influenced by British practice. Vacuum brakes also enjoyed a brief period of adoption in the United States, primarily on narrow-gauge railroads. Their limitations caused them to be progressively superseded by compressed air systems starting in the United Kingdom from the 1970s onward. The vacuum brake system is now obsolete; it is not in large-scale usage anywhere in the world, other than in South Africa, largely supplanted by air brakes.

A safety valve is a valve that acts as a fail-safe. An example of safety valve is a pressure relief valve (PRV), which automatically releases a substance from a boiler, pressure vessel, or other system, when the pressure or temperature exceeds preset limits. Pilot-operated relief valves are a specialized type of pressure safety valve. A leak tight, lower cost, single emergency use option would be a rupture disk.

A check valve, non-return valve, reflux valve, retention valve, foot valve, or one-way valve is a valve that normally allows fluid to flow through it in only one direction.

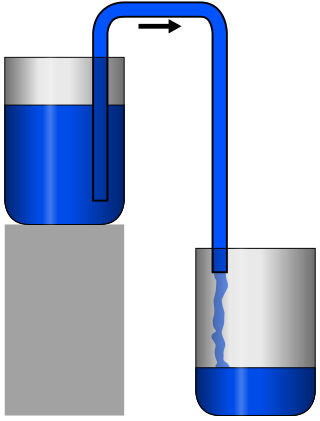

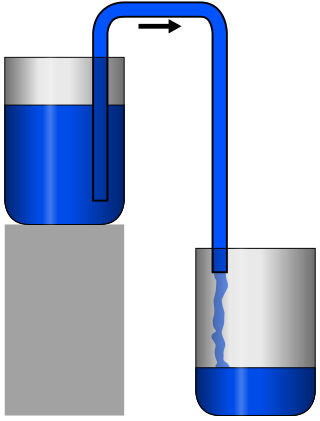

A siphon is any of a wide variety of devices that involve the flow of liquids through tubes. In a narrower sense, the word refers particularly to a tube in an inverted "U" shape, which causes a liquid to flow upward, above the surface of a reservoir, with no pump, but powered by the fall of the liquid as it flows down the tube under the pull of gravity, then discharging at a level lower than the surface of the reservoir from which it came.

A tap is a valve controlling the release of a fluid.

A backflow prevention device is used to protect potable water supplies from contamination or pollution due to backflow.

A double check valve or double check assembly (DCA) is a backflow prevention device designed to protect water supplies from contamination. It is different from the two-way check valves used in air brake systems on heavy trucks which select from the highest pressure source.

Sometimes called a check valve or a backflow preventer, a chemigation valve is an apparatus designed to protect water supplies from agricultural chemicals used during chemigation, the application of chemicals such as fertilizers and pesticides through irrigation water. Most chemigation valves consist of a spring-loaded check valve, a low pressure drain, an air and vacuum relief valve, and an injection port for introducing the chemicals downstream of the check valve. Many chemigation valves also have a 4-inch inspection port so that a person can reach inside and feel if the check valve is still functional. Some governments require the use of two chemigation valves installed in series if hazardous chemicals are to be injected.

A relief valve or pressure relief valve (PRV) is a type of safety valve used to control or limit the pressure in a system; excessive pressure might otherwise build up and create a process upset, instrument or equipment failure, explosion, or fire.

Hydronics is the use of liquid water or gaseous water (steam) or a water solution as heat-transfer medium in heating and cooling systems. The name differentiates such systems from oil and refrigerant systems.

An air gap, as related to the plumbing trade, is the unobstructed vertical space between the water outlet and the flood level of a fixture. Air gaps of appropriate design are legally required by water health and safety regulations in many countries. An air gap is the simplest form of a backflow prevention device.

A hydrostatic loop, though not often used in plumbing practice, is an arrangement of pipes formed into a vertical loop to prevent backflow of water within the plumbing potable water system. Since a siphon has a maximum height that it can work, a hydrostatic loop is built higher than 33 feet. There are several ways to prevent siphonage and an undesirable backflow of the water in a plumbing system.

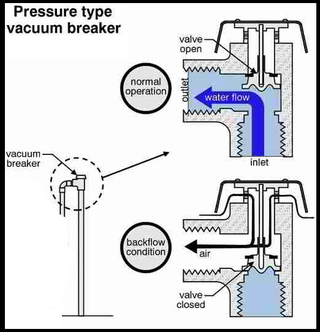

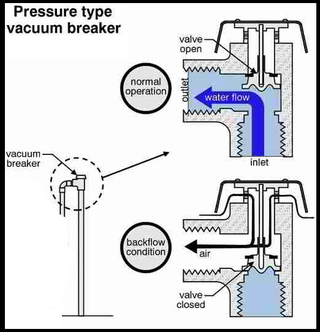

An Atmospheric Vacuum Breaker (AVB) is a backflow prevention device used in plumbing to prevent backflow of non-potable liquids into the drinking water system.

A vacuum breaker is an attachment commonly placed on a bibcock valve or toilet or urinal flush valve, that prevents water from being siphoned backward into the public drinking water system. This prevents contamination should the public drinking water system's pressure drop. A vacuum breaker is also used in steam distribution systems to prevent collapse of steam coils and pipes by letting in air when the pipe pressure becomes sub-atmospheric.

A reduced pressure zone device is a type of backflow prevention device used to protect water supplies from contamination. RPZDs may also be known as reduced pressure principle (RP), reduced pressure principle backflow prevention devices, reduced pressure zone assemblies (RPZA), or reduced pressure principle assembly (RPPA).

The first recorded rudimentary steam engine was the aeolipile mentioned by Vitruvius between 30 and 15 BC and, described by Heron of Alexandria in 1st-century Roman Egypt. Several steam-powered devices were later experimented with or proposed, such as Taqi al-Din's steam jack, a steam turbine in 16th-century Ottoman Egypt, and Thomas Savery's steam pump in 17th-century England. In 1712, Thomas Newcomen's atmospheric engine became the first commercially successful engine using the principle of the piston and cylinder, which was the fundamental type of steam engine used until the early 20th century. The steam engine was used to pump water out of coal mines.

The Bender Machine Works in Hayward, Wisconsin, is a dairy equipment manufacturer that played a major role in the history of the dairy farming business in the United States from the 1950s to the 1980s, producing milk pipeline and milk transfer cart components, and washing/vacuum-releasing equipment.

A backwater valve is a backflow prevention device used to prevent outbound water through a dwelling's drain pipes from re-entering -- "back flowing"—into a home. The valve contains a flap that allows water to exit the home, but closes to prevent the back flow into the home.

Backflow is a term in plumbing for an unwanted flow of water in the reverse direction. It can be a serious health risk for the contamination of potable water supplies with foul water. In the most obvious case, a toilet flush cistern and its water supply must be isolated from the toilet bowl. For this reason, building codes mandate a series of measures and backflow prevention devices to prevent backflow.