Plumbing is any system that conveys fluids for a wide range of applications. Plumbing uses pipes, valves, plumbing fixtures, tanks, and other apparatuses to convey fluids. Heating and cooling (HVAC), waste removal, and potable water delivery are among the most common uses for plumbing, but it is not limited to these applications. The word derives from the Latin for lead, plumbum, as the first effective pipes used in the Roman era were lead pipes.

A flange is a protruded ridge, lip or rim, either external or internal, that serves to increase strength ; for easy attachment/transfer of contact force with another object ; or for stabilizing and guiding the movements of a machine or its parts. Flanges are often attached using bolts in the pattern of a bolt circle.

A plumber is a tradesperson who specializes in installing and maintaining systems used for potable (drinking) water, hot-water production, sewage and drainage in plumbing systems.

A millwright is a craftsman or skilled tradesman who installs, dismantles, maintains, repairs, reassembles, and moves machinery in factories, power plants, and construction sites.

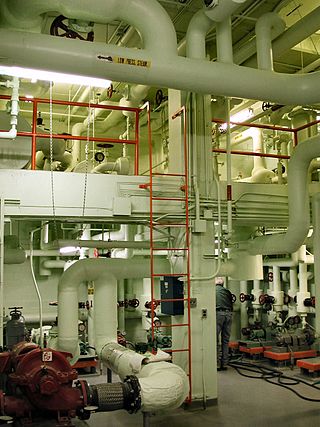

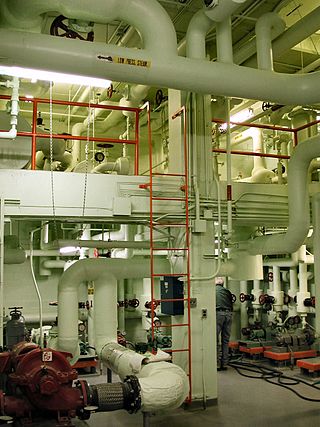

Within industry, piping is a system of pipes used to convey fluids from one location to another. The engineering discipline of piping design studies the efficient transport of fluid.

A drain-waste-vent system is the combination of pipes and plumbing fittings that captures sewage and greywater within a structure and routes it toward a water treatment system. It includes venting to the exterior environment to prevent a vacuum from forming and impeding fixtures such as sinks, showers, and toilets from draining freely, and employs water-filled traps to block dangerous sewer gasses from entering a plumbed structure.

A compression fitting is a fitting used in plumbing and electrical conduit systems to join two tubes or thin-walled pipes together. In instances where two pipes made of dissimilar materials are to be joined, the fittings will be made of one or more compatible materials appropriate for the connection. Compression fittings for attaching tubing (piping) commonly have compression rings, called ferrules or olives, in them, and are sometimes referred to as flareless fittings. There are also flare fittings that do not require ferrules/olives.

A glazier is a tradesperson responsible for cutting, installing, and removing glass. They also refer to blueprints to figure out the size, shape, and location of the glass in the building. They may have to consider the type and size of scaffolding they need to stand on to fit and install the glass. Glaziers may work with glass in various surfaces and settings, such as cutting and installing windows, doors, shower doors, skylights, storefronts, display cases, mirrors, facades, interior walls, ceilings, and tabletops.

Hydronics is the use of liquid water or gaseous water (steam) or a water solution as a heat-transfer medium in heating and cooling systems. The name differentiates such systems from oil and refrigerant systems.

A pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; a hollow pipe is far stiffer per unit weight than the solid members.

In piping and plumbing, a coupling is a very short length of pipe or tube, with a socket at one or both ends that allows two pipes or tubes to be joined, welded (steel), brazed or soldered together.

A fitting or adapter is used in pipe systems to connect sections of pipe or tube, adapt to different sizes or shapes, and for other purposes such as regulating fluid flow. These fittings are used in plumbing to manipulate the conveyance of fluids such as water for potatory, irrigational, sanitary, and refrigerative purposes, gas, petroleum, liquid waste, or any other liquid or gaseous substances required in domestic or commercial environments, within a system of pipes or tubes, connected by various methods, as dictated by the material of which these are made, the material being conveyed, and the particular environmental context in which they will be used, such as soldering, mortaring, caulking, plastic welding, welding, friction fittings, threaded fittings, and compression fittings.

Hull maintenance technician is a United States Navy occupational rating.

Plastic pipe is a tubular section, or hollow cylinder, made of plastic. It is usually, but not necessarily, of circular cross-section, used mainly to convey substances which can flow—liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; hollow pipes are far stiffer per unit weight than solid members.

Soldering is a process of joining two metal surfaces together using a filler metal called solder. The soldering process involves heating the surfaces to be joined and melting the solder, which is then allowed to cool and solidify, creating a strong and durable joint.

Pin brazing is an easy, metallurgically safe method of making electrical connections to steel and ductile iron pipelines as well as other metallic structures, which are to be cathodically protected or electrically earthed.

Copper tubing is available in two basic types of tube—plumbing tube and air conditioning/refrigeration (ACR) tube, and in both drawn (hard) and annealed (soft) tempers. Because of its high level of corrosion resistance, it is used for water distribution systems, oil fuel transfer lines, non-flammable medical-gas systems, and as a refrigerant line in HVAC systems. Copper tubing is joined using flare connection, compression connection, pressed connection, or solder.

A pipelayer is a skilled tradesman who lays pipe, such as for storm sewers, sanitary sewers, drains, and water mains. Pipelayers may grade trenches and culverts, position pipe, or seal joints. The Standard Occupational Classification System code for pipelayers is 47-2151.

In the process industry, chemical industry, manufacturing industry, and other commercial and industrial contexts, pipe marking is used to identify the contents, properties and flow direction of fluids in piping. It is typically carried out by marking piping through labels and color codes. Pipe marking helps personnel and fire response teams identify the correct pipes for operational, maintenance or emergency response purposes.