A boiler is a closed vessel in which fluid is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking, and sanitation.

A furnace, referred to as a heater or boiler in British English, is an appliance used to generate heat for all or part of a building. Furnaces are mostly used as a major component of a central heating system. Furnaces are permanently installed to provide heat to an interior space through intermediary fluid movement, which may be air, steam, or hot water. Heating appliances that use steam or hot water as the fluid are normally referred to as a residential steam boilers or residential hot water boilers. The most common fuel source for modern furnaces in North America and much of Europe is natural gas; other common fuel sources include LPG, fuel oil, wood and in rare cases coal. In some areas electrical resistance heating is used, especially where the cost of electricity is low or the primary purpose is for air conditioning. Modern high-efficiency furnaces can be up to 98% efficient and operate without a chimney, with a typical gas furnace being about 80% efficient. Waste gas and heat are mechanically ventilated through either metal flue pipes or polyvinyl chloride (PVC) pipes that can be vented through the side or roof of the structure. Fuel efficiency in a gas furnace is measured in AFUE.

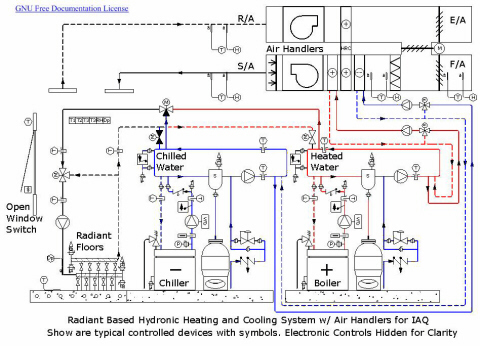

A central heating system provides warmth to a number of spaces within a building from one main source of heat. It is a component of heating, ventilation, and air conditioning systems, which can both cool and warm interior spaces.

An air handler, or air handling unit, is a device used to regulate and circulate air as part of a heating, ventilating, and air-conditioning (HVAC) system. An air handler is usually a large metal box containing a blower, furnace or A/C elements, filter racks or chambers, sound attenuators, and dampers. Air handlers usually connect to a ductwork ventilation system that distributes the conditioned air through the building and returns it to the AHU, sometimes exhausting air to the atmosphere and bringing in fresh air. Sometimes AHUs discharge (supply) and admit (return) air directly to and from the space served without ductwork

A thermal power station is a type of power station in which heat energy is converted to electrical energy. In a steam-generating cycle heat is used to boil water in a large pressure vessel to produce high-pressure steam, which drives a steam turbine connected to an electrical generator. The low-pressure exhaust from the turbine enters a steam condenser where it is cooled to produce hot condensate which is recycled to the heating process to generate more high pressure steam. This is known as a Rankine cycle.

Thermosiphon is a method of passive heat exchange, based on natural convection, which circulates a fluid without the necessity of a mechanical pump. Thermosiphoning is used for circulation of liquids and volatile gases in heating and cooling applications such as heat pumps, water heaters, boilers and furnaces. Thermosiphoning also occurs across air temperature gradients such as those utilized in a wood fire chimney or solar chimney.

A surface condenser is a water-cooled shell and tube heat exchanger installed to condense exhaust steam from a steam turbine in thermal power stations. These condensers are heat exchangers which convert steam from its gaseous to its liquid state at a pressure below atmospheric pressure. Where cooling water is in short supply, an air-cooled condenser is often used. An air-cooled condenser is however, significantly more expensive and cannot achieve as low a steam turbine exhaust pressure as a water-cooled surface condenser.

A forced-air central heating system is one which uses air as its heat transfer medium. These systems rely on ductwork, vents, and plenums as means of air distribution, separate from the actual heating and air conditioning systems. The return plenum carries the air from several large return grills (vents) to a central air handler for re-heating. The supply plenum directs air from the central unit to the rooms which the system is designed to heat. Regardless of type, all air handlers consist of an air filter, blower, heat exchanger/element/coil, and various controls. Like any other kind of central heating system, thermostats are used to control forced air heating systems.

A circulator pump or circulating pump is a specific type of pump used to circulate gases, liquids, or slurries in a closed circuit. They are commonly found circulating water in a hydronic heating or cooling system. Because they only circulate liquid within a closed circuit, they only need to overcome the friction of a piping system.

A condensate pump is a specific type of pump used to pump the condensate (water) produced in an HVAC, refrigeration, condensing boiler furnace, or steam system.

Condensing boilers are water heaters typically used for heating systems that are fueled by gas or oil. When operated in the correct circumstances, a heating system can achieve high efficiency by condensing water vapour found in the exhaust gases in a heat exchanger to preheat the circulating water. This recovers the latent heat of vaporisation, which would otherwise have been wasted. The condensate is sent to a drain. In many countries, the use of condensing boilers is compulsory or encouraged with financial incentives.

Underfloor heating and cooling is a form of central heating and cooling that achieves indoor climate control for thermal comfort using hydronic or electrical heating elements embedded in a floor. Heating is achieved by conduction, radiation and convection. Use of underfloor heating dates back to the Neoglacial and Neolithic periods.

A fan coil unit (FCU), also known as a Vertical Fan Coil-Unit (VFC), is a device consisting of a heat exchanger (coil) and a fan. FCUs are commonly used in HVAC systems of residential, commercial, and industrial buildings that use ducted split air conditioning or with central plant cooling. FCUs are typically connected to ductwork and a thermostat to regulate the temperature of one or more spaces and to assist the main air handling unit for each space if used with chillers. The thermostat controls the fan speed and/or the flow of water or refrigerant to the heat exchanger using a control valve.

Radiators and convectors are heat exchangers designed to transfer thermal energy from one medium to another for the purpose of space heating.

Hydronic balancing, also called hydraulic balancing, is the process of optimizing the distribution of water in a building's hydronic heating or cooling system by equalizing the system pressure. In a balanced system every radiator is set to receive the proper amount of fluid in order to provide the intended indoor climate at optimum energy efficiency and minimal operating cost.

Automatic balancing valves are utilised in central heating and cooling systems that rely on flow of water through the system. They use the latest flow technology to ensure that the design flow rate is achieved at all times irrespective of any pressure changes within the system.

The Uniform Mechanical Code (UMC) is a model code developed by the International Association of Plumbing and Mechanical Officials (IAPMO) to govern the installation, inspection and maintenance of HVAC and refrigeration systems. It is designated as an American National Standard.

Tankless water heaters — also called instantaneous, continuous flow, inline, flash, on-demand, or instant-on water heaters — are water heaters that instantly heat water as it flows through the device, and do not retain any water internally except for what is in the heat exchanger coil unless the unit is equipped with an internal buffer tank. Copper heat exchangers are preferred in these units because of their high thermal conductivity and ease of fabrication. However, copper heat exchangers are more susceptible to scale buildup than stainless steel heat exchangers.

The Glossary of Geothermal Heating and Cooling provides definitions of many terms used within the Geothermal heat pump industry. The terms in this glossary may be used by industry professionals, for education materials, and by the general public.

An automatic bleeding valve or air release valve (ARV) is a plumbing valve used to automatically release trapped air from a heating system.