Turboswing is a type of grease filter used in kitchen ventilation to remove grease particles from the air. It is typically installed inside the extractor hoods of restaurant kitchens. Its operation is based on a rotating filtering medium. [1] [2]

Turboswing is a type of grease filter used in kitchen ventilation to remove grease particles from the air. It is typically installed inside the extractor hoods of restaurant kitchens. Its operation is based on a rotating filtering medium. [1] [2]

The main difference between turboswing and most common filters is that in turboswing filters the filtering medium is not static. There is a perforated disk rotating at high speed. [1] When the grease particles go through the rotating disk they are separated from the air.

After separation, centrifugal force due to the rotating disk throws particles against the inner walls of the filter. [3] Particles then drip down the walls of the chamber onto the lower collection basin, where they stay until they are removed through the tap at the bottom of the filter dome. [4]

Turboswing filters can remove grease particles starting from 4μm, as opposed to 8μm for common filters. This is because the filtering medium is moving, and this increases the probability of collision between the filter and the particle. [1] [5] [6] [7]

Turboswing filters can work with varying airflows. The grease extraction level is not affected by the airflow. This means that this kind of filter can be used in restaurants that turn down the air volumes at non-peak times in order to save energy.

The explanation is that if the airflow is lower, the particles go through the rotating disk at a slower speed, therefore increasing, the collision probability. Other filters like cyclonic filters require the airflow to be high on a permanent basis, or else the performance of the filter drops. Therefore, the use of filters like turboswing make it possible to save vast amounts of energy in restaurant kitchen ventilation. [8] [9]

Turboswing grease filters make it possible to do heat recovery with the air of a kitchen. [10] Unlike common filters, turboswing filters extract the small particles responsible for making the heat exchanger dirty. [5]

Heat recovery makes it possible to save energy in the ventilation of a building. In particular, kitchen air is hotter than the air in most other rooms, and therefore a large amount of energy can potentially be saved. However, when it comes to the ventilation of a kitchen, if the correct kind of filter is not used, heat recovery can be very difficult or even impossible, because of the presence of grease particles in the air. Grease particles accumulate at the heat exchanger, rendering it useless very quickly. [11]

In order to have heat recovery in a kitchen, the air must be completely clear of grease, in other words, both large and small grease particles must be removed from the air. Static filters cannot adequately deal with small particles, therefore making it impossible to recover heat. Turboswing filters exhibit high performance in dealing with small particles, and this is why they enable heat recovery to be done with kitchen air. [1] [11]

Heating, ventilation, and air conditioning (HVAC) is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality. HVAC system design is a subdiscipline of mechanical engineering, based on the principles of thermodynamics, fluid mechanics, and heat transfer. "Refrigeration" is sometimes added to the field's abbreviation as HVAC&R or HVACR, or "ventilation" is dropped, as in HACR.

A dehumidifier is an air conditioning device which reduces and maintains the level of humidity in the air. This is done usually for health or thermal comfort reasons, or to eliminate musty odor and to prevent the growth of mildew by extracting water from the air. It can be used for household, commercial, or industrial applications. Large dehumidifiers are used in commercial buildings such as indoor ice rinks and swimming pools, as well as manufacturing plants or storage warehouses. Typical air conditioning systems combine dehumidification with cooling, by operating cooling coils below the dewpoint and draining away the water that condenses.

HEPA filter, also known as high-efficiency particulate absorbing filter and high-efficiency particulate arrestance filter, is an efficiency standard of air filters.

Cyclonic separation is a method of removing particulates from an air, gas or liquid stream, without the use of filters, through vortex separation. When removing particulate matter from liquid, a hydrocyclone is used; while from gas, a gas cyclone is used. Rotational effects and gravity are used to separate mixtures of solids and fluids. The method can also be used to separate fine droplets of liquid from a gaseous stream.

A kitchen hood, exhaust hood, extractor hood, or range hood is a device containing a mechanical fan that hangs above the stove or cooktop in the kitchen. It removes airborne grease, combustion products, fumes, smoke, heat, and steam from the air by evacuation of the air and filtration. In commercial kitchens exhaust hoods are often used in combination with fire suppression devices so that fumes from a grease fire are properly vented and the fire is put out quickly. Commercial vent hoods may also be combined with a fresh air fan that draws in exterior air, circulating it with the cooking fumes, which is then drawn out by the hood.

Heat recovery ventilation (HRV), also known as mechanical ventilation heat recovery (MVHR), is an energy recovery ventilation system which works between two air sources at different temperatures. Heat recovery is a method that is used to reduce the heating and cooling demands of buildings. By recovering the residual heat in the exhaust gas, the fresh air introduced into the air conditioning system is preheated (pre-cooled) and the fresh air enthalpy is increased (reduced) before the fresh air enters the room or the air cooler of the air conditioning unit performs heat and moisture treatment. A typical heat recovery system in buildings consists of a core unit, channels for fresh and exhaust air, and blower fans. Building exhaust air is used as either a heat source or heat sink depending on the climate conditions, time of year, and requirements of the building. Heat recovery systems typically recover about 60–95% of the heat in the exhaust air and have significantly improved the energy efficiency of buildings.

A deep fryer, is a kitchen appliance used for deep frying. Deep frying is a method of cooking by submerging food into oil at high heat, typically between temperatures of 350 to 375 °F.

A particulate air filter is a device composed of fibrous, or porous materials which removes solid particulates such as dust, pollen, mold, and bacteria from the air. Filters containing an adsorbent or catalyst such as charcoal (carbon) may also remove odors and gaseous pollutants such as volatile organic compounds or ozone. Air filters are used in applications where air quality is important, notably in building ventilation systems and in engines.

A dust collector is a system used to enhance the quality of air released from industrial and commercial processes by collecting dust and other impurities from air or gas. Designed to handle high-volume dust loads, a dust collector system consists of a blower, dust filter, a filter-cleaning system, and a dust receptacle or dust removal system. It is distinguished from air purifiers, which use disposable filters to remove dust.

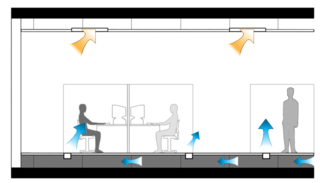

Displacement ventilation (DV) It is a room air distribution strategy where conditioned outdoor air is supplied at a low velocity from air supply diffusers located near floor level and extracted above the occupied zone, usually at ceiling height.

Variable air volume (VAV) is a type of heating, ventilating, and/or air-conditioning (HVAC) system. Unlike constant air volume (CAV) systems, which supply a constant airflow at a variable temperature, VAV systems vary the airflow at a constant or varying temperature. The advantages of VAV systems over constant-volume systems include more precise temperature control, reduced compressor wear, lower energy consumption by system fans, less fan noise, and additional passive dehumidification.

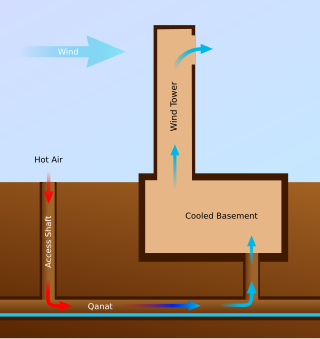

A ground-coupled heat exchanger is an underground heat exchanger that can capture heat from and/or dissipate heat to the ground. They use the Earth's near constant subterranean temperature to warm or cool air or other fluids for residential, agricultural or industrial uses. If building air is blown through the heat exchanger for heat recovery ventilation, they are called earth tubes.

Energy recovery ventilation (ERV) is the energy recovery process in residential and commercial HVAC systems that exchanges the energy contained in normally exhausted air of a building or conditioned space, using it to treat (precondition) the incoming outdoor ventilation air. The specific equipment involved may be called an Energy Recovery Ventilator, also abbreviated ERV.

Passive ventilation is the process of supplying air to and removing air from an indoor space without using mechanical systems. It refers to the flow of external air to an indoor space as a result of pressure differences arising from natural forces.

Compressed air filters, often referred to as line filters, are used to remove contaminants from compressed air after compression has taken place.

Underfloor air distribution (UFAD) is an air distribution strategy for providing ventilation and space conditioning in buildings as part of the design of a HVAC system. UFAD systems use an underfloor supply plenum located between the structural concrete slab and a raised floor system to supply conditioned air to supply outlets, located at or near floor level within the occupied space. Air returns from the room at ceiling level or the maximum allowable height above the occupied zone.

The clean air delivery rate (CADR) is a figure of merit that is the cubic feet per minute (CFM) of air that has had all the particles of a given size distribution removed. For air filters that have air flowing through them, it is the fraction of particles that have been removed from the air, multiplied by the air flow rate through the device. More precisely, it is the CFM of air in a 1,008-cubic-foot (28.5 m3) room that has had all the particles of a given size distribution removed from the air, over and above the rate at which the particles are naturally falling out of the air. Different filters have different abilities to remove different particle distributions, so three CADR's for a given device are typically measured: smoke, pollen, and dust. By combining the amount of airflow and particle removal efficiency, consumers are less likely to be misled by a high efficiency filter that is filtering a small amount of air, or by a high volume of air that is not being filtered very well.

Kitchen ventilation is the branch of ventilation specialising in the treatment of air from kitchens. It addresses the problems of grease, smoke and odours not found in most other ventilation systems.

Airflow, or air flow, is the movement of air. The primary cause of airflow is the existence of air. Air behaves in a fluid manner, meaning particles naturally flow from areas of higher pressure to those where the pressure is lower. Atmospheric air pressure is directly related to altitude, temperature, and composition.

Air filtration guidelines for operating rooms are determined by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) using a standard known as Minimum Efficiency Reporting Value (MERV). MERV is determined based on the size of particles successfully removed from the air and is used to classify the efficiency of HEPA filters. Ratings range from 1-16 and efficiency increases as the rating increases. ASHRAE groups surgeries into three categories: minor surgical procedures (A); minor or major surgical procedures performed with minor sedation (B); and major surgical procedures performed with general anesthesia or regional block anesthesia (C). Each surgical category is given a minimum MERV rating it must comply with.