Heating, ventilation, and air conditioning (HVAC) is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality. HVAC system design is a subdiscipline of mechanical engineering, based on the principles of thermodynamics, fluid mechanics, and heat transfer. "Refrigeration" is sometimes added to the field's abbreviation as HVAC&R or HVACR, or "ventilation" is dropped, as in HACR.

A dehumidifier is an air conditioning device which reduces and maintains the level of humidity in the air. This is done usually for health or thermal comfort reasons, or to eliminate musty odor and to prevent the growth of mildew by extracting water from the air. It can be used for household, commercial, or industrial applications. Large dehumidifiers are used in commercial buildings such as indoor ice rinks and swimming pools, as well as manufacturing plants or storage warehouses. Typical air conditioning systems combine dehumidification with cooling, by operating cooling coils below the dewpoint and draining away the water that condenses.

An evaporative cooler is a device that cools air through the evaporation of water. Evaporative cooling differs from other air conditioning systems, which use vapor-compression or absorption refrigeration cycles. Evaporative cooling exploits the fact that water will absorb a relatively large amount of heat in order to evaporate. The temperature of dry air can be dropped significantly through the phase transition of liquid water to water vapor (evaporation). This can cool air using much less energy than refrigeration. In extremely dry climates, evaporative cooling of air has the added benefit of conditioning the air with more moisture for the comfort of building occupants.

Heat recovery ventilation (HRV), also known as mechanical ventilation heat recovery (MVHR), is an energy recovery ventilation system that operates between two air sources at different temperatures. It's a method that is used to reduce the heating and cooling demands of buildings. By recovering the residual heat in the exhaust gas, the fresh air introduced into the air conditioning system is preheated, and the fresh air's enthalpy is reduced before it enters the room, or the air cooler of the air conditioning unit performs heat and moisture treatment. A typical heat recovery system in buildings comprises a core unit, channels for fresh and exhaust air, and blower fans. Building exhaust air is used as either a heat source or heat sink, depending on the climate conditions, time of year, and requirements of the building. Heat recovery systems typically recover about 60–95% of the heat in the exhaust air and have significantly improved the energy efficiency of buildings.

A recuperator is a special purpose counter-flow energy recovery heat exchanger positioned within the supply and exhaust air streams of an air handling system, or in the exhaust gases of an industrial process, in order to recover the waste heat. Generally, they are used to extract heat from the exhaust and use it to preheat air entering the combustion system. In this way they use waste energy to heat the air, offsetting some of the fuel, and thereby improve the energy efficiency of the system as a whole.

An air handler, or air handling unit, is a device used to regulate and circulate air as part of a heating, ventilating, and air-conditioning (HVAC) system. An air handler is usually a large metal box containing a blower, furnace or A/C elements, filter racks or chambers, sound attenuators, and dampers. Air handlers usually connect to a ductwork ventilation system that distributes the conditioned air through the building and returns it to the AHU, sometimes exhausting air to the atmosphere and bringing in fresh air. Sometimes AHUs discharge (supply) and admit (return) air directly to and from the space served without ductwork

Economizers, or economisers (UK), are mechanical devices intended to reduce energy consumption, or to perform useful function such as preheating a fluid. The term economizer is used for other purposes as well. Boiler, power plant, heating, refrigeration, ventilating, and air conditioning (HVAC) uses are discussed in this article. In simple terms, an economizer is a heat exchanger.

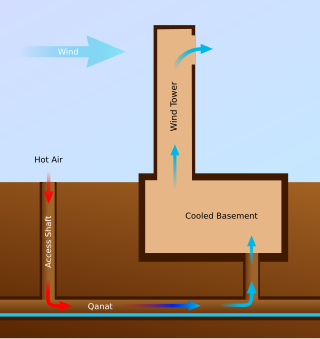

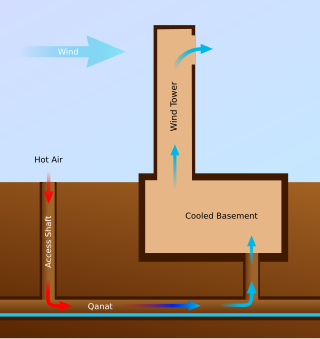

A ground-coupled heat exchanger is an underground heat exchanger that can capture heat from and/or dissipate heat to the ground. They use the Earth's near constant subterranean temperature to warm or cool air or other fluids for residential, agricultural or industrial uses. If building air is blown through the heat exchanger for heat recovery ventilation, they are called earth tubes.

Underfloor heating and cooling is a form of central heating and cooling that achieves indoor climate control for thermal comfort using hydronic or electrical heating elements embedded in a floor. Heating is achieved by conduction, radiation and convection. Use of underfloor heating dates back to the Neoglacial and Neolithic periods.

Energy recovery includes any technique or method of minimizing the input of energy to an overall system by the exchange of energy from one sub-system of the overall system with another. The energy can be in any form in either subsystem, but most energy recovery systems exchange thermal energy in either sensible or latent form.

Passive ventilation is the process of supplying air to and removing air from an indoor space without using mechanical systems. It refers to the flow of external air to an indoor space as a result of pressure differences arising from natural forces.

Infiltration is the unintentional or accidental introduction of outside air into a building, typically through cracks in the building envelope and through use of doors for passage. Infiltration is sometimes called air leakage. The leakage of room air out of a building, intentionally or not, is called exfiltration. Infiltration is caused by wind, negative pressurization of the building, and by air buoyancy forces known commonly as the stack effect.

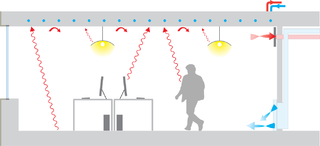

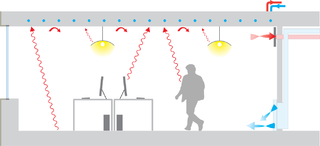

A chilled beam is a type of radiation/convection HVAC system designed to heat and cool large buildings through the use of water. This method removes most of the zone sensible local heat gains and allows the flow rate of pre-conditioned air from the air handling unit to be reduced, lowering by 60% to 80% the ducted design airflow rate and the equipment capacity requirements. There are two types of chilled beams, a Passive Chilled Beam (PCB) and an Active Chilled Beam (ACB). They both consist of pipes of water (fin-and-tube) that pass through a heat exchanger contained in a case suspended from, or recessed in, the ceiling. As the beam cools the air around it, the air becomes denser and falls to the floor. It is replaced by warmer air moving up from below, causing a constant passive air movement called convection, to cool the room. The active beam consists of air duct connections, induction nozzles, hydronic heat transfer coils, supply outlets and induced air inlets. It contains an integral air supply that passes through nozzles, and induces air from the room to the cooling coil. For this reason, it has a better cooling capacity than the passive beam. Instead, the passive beam provides space cooling without the use of a fan and it is mainly done by convection. Passive beams can be either exposed or recessed. The passive approach can provide higher thermal comfort levels, while the active approach uses the momentum of ventilation air that enters at relatively high velocity to induce the circulation of room air through the unit. A chilled beam is similar in appearance to a VRF unit.

HVAC is a major sub discipline of mechanical engineering. The goal of HVAC design is to balance indoor environmental comfort with other factors such as installation cost, ease of maintenance, and energy efficiency. The discipline of HVAC includes a large number of specialized terms and acronyms, many of which are summarized in this glossary.

A dedicated outdoor air system (DOAS) is a type of heating, ventilation and air-conditioning (HVAC) system that consists of two parallel systems: a dedicated system for delivering outdoor air ventilation that handles both the latent and sensible loads of conditioning the ventilation air, and a parallel system to handle the loads generated by indoor/process sources and those that pass through the building enclosure.

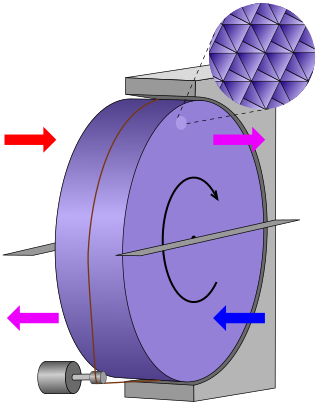

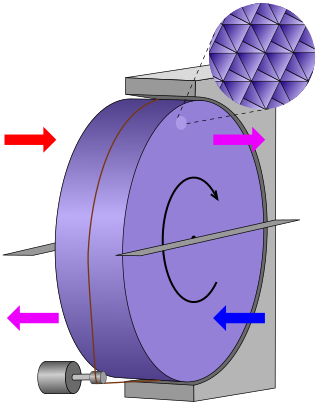

A thermal wheel, also known as a rotary heat exchanger, or rotary air-to-air enthalpy wheel, energy recovery wheel, or heat recovery wheel, is a type of energy recovery heat exchanger positioned within the supply and exhaust air streams of air-handling units or rooftop units or in the exhaust gases of an industrial process, in order to recover the heat energy. Other variants include enthalpy wheels and desiccant wheels. A cooling-specific thermal wheel is sometimes referred to as a Kyoto wheel.

A run-around coil is a type of energy recovery heat exchanger most often positioned within the supply and exhaust air streams of an air handling system, or in the exhaust gases of an industrial process, to recover the heat energy. Generally, it refers to any intermediate stream used to transfer heat between two streams that are not directly connected for reasons of safety or practicality. It may also be referred to as a run-around loop, a pump-around coil or a liquid coupled heat exchanger.

Radiant heating and cooling is a category of HVAC technologies that exchange heat by both convection and radiation with the environments they are designed to heat or cool. There are many subcategories of radiant heating and cooling, including: "radiant ceiling panels", "embedded surface systems", "thermally active building systems", and infrared heaters. According to some definitions, a technology is only included in this category if radiation comprises more than 50% of its heat exchange with the environment; therefore technologies such as radiators and chilled beams are usually not considered radiant heating or cooling. Within this category, it is practical to distinguish between high temperature radiant heating, and radiant heating or cooling with more moderate source temperatures. This article mainly addresses radiant heating and cooling with moderate source temperatures, used to heat or cool indoor environments. Moderate temperature radiant heating and cooling is usually composed of relatively large surfaces that are internally heated or cooled using hydronic or electrical sources. For high temperature indoor or outdoor radiant heating, see: Infrared heater. For snow melt applications see: Snowmelt system.

Cooling load is the rate at which sensible and latent heat must be removed from the space to maintain a constant space dry-bulb air temperature and humidity. Sensible heat into the space causes its air temperature to rise while latent heat is associated with the rise of the moisture content in the space. The building design, internal equipment, occupants, and outdoor weather conditions may affect the cooling load in a building using different heat transfer mechanisms. The SI units are watts.

The Cromer cycle is a thermodynamic cycle that uses a desiccant to interact with higher relative humidity air leaving a cold surface. When a system is taken through a series of different states and finally returned to its initial state, a thermodynamic cycle is said to have occurred. The desiccant absorbs moisture from the air leaving the cold surface, releasing heat and drying the air, which can be used in a process requiring dry air. The desiccant is then dried by an air stream at a lower relative humidity, where the desiccant gives up its moisture by evaporation, increasing the air's relative humidity and cooling it. This cooler, moister air can then be presented to the same cold surface as above to take it below its dew point and dry it further, or it can be expunged from the system.