Thermal destratification is the process of mixing the internal air in a building to eliminate stratified layers and achieve temperature equalization throughout the building envelope.

Thermal destratification is the process of mixing the internal air in a building to eliminate stratified layers and achieve temperature equalization throughout the building envelope.

Destratification is the reverse of the natural process of thermal stratification, which is the layering of differing (typically increasing) air temperatures from floor to ceiling. Stratification is caused by hot air rising up to the ceiling or roof space because it is lighter than the surrounding cooler air. Conversely, cool air falls to the floor as it is heavier than the surrounding warmer air.[ citation needed ]

In a stratified building, temperature differentials of up to 1.5°C per vertical foot is common, and the higher a building's ceiling, the more extreme this temperature differential can be. [2] In extreme cases, temperature differentials of 10°C have been found over a height of 1 meter. Other variables that influence the level of thermal stratification include heat generated by people and processes present in the building, insulation of the space from outside weather conditions, solar gain, specification of the HVAC system, location of supply and return ducts, and vertical air movement inside the space, usually supplied by destratification fans. Computational fluid dynamics can be used to predict the level of stratification in a space.[ citation needed ]

In a study conducted by the Building Scientific Research Information Association, the wasted energy due to stratification increased consistently based on temperature differential from floor to ceiling (ΔT). [3] The study indicates that stratified buildings tend to overheat or overcool based on the temperature at the thermostat, which tends to be lower than the overall heat energy present in the room. The study also showed that energy waste due to stratification was present at ceiling heights ranging from 20 ft. to 40 ft, and higher ceilings caused higher energy waste, even at the same ΔT. Since ΔT tends to be higher in taller ceilings, the effect of stratification is compounded, causing substantial energy waste in high-ceiling buildings.

Since stratification and the costs associated with it are linear, the definition of destratification will differ based on opinion and use case. Full destratification, or a 0° ΔT from floor to ceiling, is unlikely to occur in any building. Since the costs of stratification decrease linearly as ΔT approaches 5.4°F, and no study has yet looked at the effects of stratification below 5.4°F, it is not uncommon to consider any space with a ΔT below 5°F to be destratified. In the United States, ASHRAE Standard 55 prescribes 3°C as the limit for the vertical air temperature difference between head and ankle levels, but has no standard recommending an ideal ΔT between floor and ceiling. [4]

Reducing thermal stratification can be accomplished by controlling the variables that are associated with increased stratification. Since many of the variables, including ceiling height, people and processes, solar gain, and outside weather conditions cannot be controlled, the most common technologies used are related to the building's HVAC (heating, ventilation, and air conditioning) system. One of the cheapest, most effective, and easiest to install technologies are destratification fans, including both axial destratification fans and HVLS (high-volume low-speed) fans.[ citation needed ]

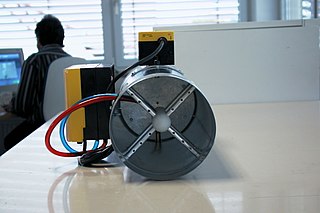

Axial destratification fans are self-contained units that are installed in an array at the ceiling with the goal of blowing conditioned air in the ceiling down to the floor, where people live and work. Because axial fans are designed to blow air straight down at the floor, they can be used in ceiling and roof structures over 100 ft. tall. Because axial destratification fans can achieve destratification with low CFMs, it is imperative that the air leaving the nozzle achieve an air speed at the floor of between 0.2 and 0.5 m/s. The result of this level of air movement is the integration of conditioned air from the ceiling with air at the floor level. Failing to impact the floor will result in destratification of medial layers of air but not achieve destratification at the floor. Since the area around the thermostat will not be destratified in this instance, it is hypothesized that there will be little or no cost savings, as the thermostat will continue to overheat or overcool the room.

An experiment in a room with a 21 ft. ceiling yielded a savings of 23.5% with the use of axial destratification fans. [5]

Because of their size, HVLS fans are normally installed in new construction, rather than retrofits, as the roof structure may have to be redesigned to accommodate the increased weight and size. It's not uncommon to require the relocation of lights, due to strobing as large fan blades pass under them, and sprinkler systems, which typically require unobstructed access to the floor to meet fire code. When used in the summer to encourage evaporative cooling, HVLS fans are run forward, blowing air at the floor. When used for destratification in the winter, the fans are run in reverse, blowing air towards ceiling which then circulates around the room. The height at which HVLS fans can be effective is limited compared to axial destratification fans.

This method has the most benefits through its application in the heating, ventilation, and air conditioning (HVAC) industry and in heating and cooling for buildings and it has been found that "stratification is the single biggest waste of energy in buildings today." [6]

By incorporating thermal destratification technology into buildings, energy requirements are reduced as heating systems are no longer over-delivering in order to constantly replace the heat that rises away from the floor area, by redistributing the already heated air from the unoccupied ceiling space back down to floor level, until temperature equalisation is achieved. With regards to cooling destratification systems ensure the cooled air supplied is circulated fully and distributed evenly throughout internal environments, eliminating hot and cold spots and satisfying thermostats for longer periods of time. As a result, destratification technology has great potential for carbon emission reductions due to the reduced energy requirement, and is in turn capable of cutting costs for businesses, sometimes by up to 50%. [7] This is supported by The Carbon Trust which recommends destratification in buildings as one of its top three methods to reduce carbon dioxide emissions. [8]

Destratification naturally increases air movement at the floor, reducing "hot spots" and "cold spots" in a room. It can be used in typically cold areas, like grocery store freezer cases, to warm patrons shopping nearby. In addition, air movement from destratification fans can be used to help meet ASHRAE Standard 62.1 by increasing the amount of air movement at the floor.

Heating, ventilation, and air conditioning (HVAC) is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality. HVAC system design is a subdiscipline of mechanical engineering, based on the principles of thermodynamics, fluid mechanics, and heat transfer. "Refrigeration" is sometimes added to the field's abbreviation as HVAC&R or HVACR, or "ventilation" is dropped, as in HACR.

A thermostat is a regulating device component which senses the temperature of a physical system and performs actions so that the system's temperature is maintained near a desired setpoint.

Ventilation is the intentional introduction of outdoor air into a space. Ventilation is mainly used to control indoor air quality by diluting and displacing indoor pollutants; it can also be used to control indoor temperature, humidity, and air motion to benefit thermal comfort, satisfaction with other aspects of the indoor environment, or other objectives.

Electric heating is a process in which electrical energy is converted directly to heat energy. Common applications include space heating, cooking, water heating and industrial processes. An electric heater is an electrical device that converts an electric current into heat. The heating element inside every electric heater is an electrical resistor, and works on the principle of Joule heating: an electric current passing through a resistor will convert that electrical energy into heat energy. Most modern electric heating devices use nichrome wire as the active element; the heating element, depicted on the right, uses nichrome wire supported by ceramic insulators.

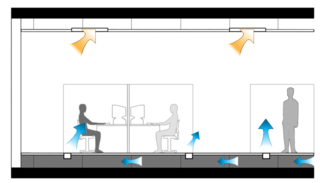

Displacement ventilation (DV) is a room air distribution strategy where conditioned outdoor air is supplied at a low velocity from air supply diffusers located near floor level and extracted above the occupied zone, usually at ceiling height.

Variable air volume (VAV) is a type of heating, ventilating, and/or air-conditioning (HVAC) system. Unlike constant air volume (CAV) systems, which supply a constant airflow at a variable temperature, VAV systems vary the airflow at a constant or varying temperature. The advantages of VAV systems over constant-volume systems include more precise temperature control, reduced compressor wear, lower energy consumption by system fans, less fan noise, and additional passive dehumidification.

Underfloor heating and cooling is a form of central heating and cooling that achieves indoor climate control for thermal comfort using hydronic or electrical heating elements embedded in a floor. Heating is achieved by conduction, radiation and convection. Use of underfloor heating dates back to the Neoglacial and Neolithic periods.

Forced-air gas heating systems are used in central air heating/cooling systems for houses. Sometimes the system is referred to as "forced hot air".

Passive ventilation is the process of supplying air to and removing air from an indoor space without using mechanical systems. It refers to the flow of external air to an indoor space as a result of pressure differences arising from natural forces.

Constant air volume (CAV) is a type of heating, ventilating, and air-conditioning (HVAC) system. In a simple CAV system, the supply air flow rate is constant, but the supply air temperature is varied to meet the thermal loads of a space.

Room air distribution is characterizing how air is introduced to, flows through, and is removed from spaces. HVAC airflow in spaces generally can be classified by two different types: mixing and displacement.

A chilled beam is a type of radiation/convection HVAC system designed to heat and cool large buildings through the use of water. This method removes most of the zone sensible local heat gains and allows the flow rate of pre-conditioned air from the air handling unit to be reduced, lowering by 60% to 80% the ducted design airflow rate and the equipment capacity requirements. There are two types of chilled beams, a Passive Chilled Beam (PCB) and an Active Chilled Beam (ACB). They both consist of pipes of water (fin-and-tube) that pass through a heat exchanger contained in a case suspended from, or recessed in, the ceiling. As the beam cools the air around it, the air becomes denser and falls to the floor. It is replaced by warmer air moving up from below, causing a constant passive air movement called convection, to cool the room. The active beam consists of air duct connections, induction nozzles, hydronic heat transfer coils, supply outlets and induced air inlets. It contains an integral air supply that passes through nozzles, and induces air from the room to the cooling coil. For this reason, it has a better cooling capacity than the passive beam. Instead, the passive beam provides space cooling without the use of a fan and it is mainly done by convection. Passive beams can be either exposed or recessed. The passive approach can provide higher thermal comfort levels, while the active approach uses the momentum of ventilation air that enters at relatively high velocity to induce the circulation of room air through the unit. A chilled beam is similar in appearance to a VRF unit.

A fan coil unit (FCU), also known as a Vertical Fan Coil-Unit (VFC), is a device consisting of a heat exchanger (coil) and a fan. FCUs are commonly used in HVAC systems of residential, commercial, and industrial buildings that use ducted split air conditioning or with central plant cooling. FCUs are typically connected to ductwork and a thermostat to regulate the temperature of one or more spaces and to assist the main air handling unit for each space if used with chillers. The thermostat controls the fan speed and/or the flow of water or refrigerant to the heat exchanger using a control valve.

HVAC is a major sub discipline of mechanical engineering. The goal of HVAC design is to balance indoor environmental comfort with other factors such as installation cost, ease of maintenance, and energy efficiency. The discipline of HVAC includes a large number of specialized terms and acronyms, many of which are summarized in this glossary.

Underfloor air distribution (UFAD) is an air distribution strategy for providing ventilation and space conditioning in buildings as part of the design of a HVAC system. UFAD systems use an underfloor supply plenum located between the structural concrete slab and a raised floor system to supply conditioned air to supply outlets, located at or near floor level within the occupied space. Air returns from the room at ceiling level or the maximum allowable height above the occupied zone.

A dedicated outdoor air system (DOAS) is a type of heating, ventilation and air-conditioning (HVAC) system that consists of two parallel systems: a dedicated system for delivering outdoor air ventilation that handles both the latent and sensible loads of conditioning the ventilation air, and a parallel system to handle the loads generated by indoor/process sources and those that pass through the building enclosure.

A high-volume low-speed (HVLS) fan is a type of mechanical fan greater than 7 feet (2.1 m) in diameter. HVLS fans are generally ceiling fans although some are pole mounted. HVLS fans move slowly and distribute large amounts of air at low rotational speed– hence the name "high volume, low speed."

Airflow, or air flow, is the movement of air. The primary cause of airflow is the existence of air. Air behaves in a fluid manner, meaning particles naturally flow from areas of higher pressure to those where the pressure is lower. Atmospheric air pressure is directly related to altitude, temperature, and composition.

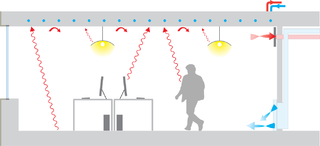

Radiant heating and cooling is a category of HVAC technologies that exchange heat by both convection and radiation with the environments they are designed to heat or cool. There are many subcategories of radiant heating and cooling, including: "radiant ceiling panels", "embedded surface systems", "thermally active building systems", and infrared heaters. According to some definitions, a technology is only included in this category if radiation comprises more than 50% of its heat exchange with the environment; therefore technologies such as radiators and chilled beams are usually not considered radiant heating or cooling. Within this category, it is practical to distinguish between high temperature radiant heating, and radiant heating or cooling with more moderate source temperatures. This article mainly addresses radiant heating and cooling with moderate source temperatures, used to heat or cool indoor environments. Moderate temperature radiant heating and cooling is usually composed of relatively large surfaces that are internally heated or cooled using hydronic or electrical sources. For high temperature indoor or outdoor radiant heating, see: Infrared heater. For snow melt applications see: Snowmelt system.

Cooling load is the rate at which sensible and latent heat must be removed from the space to maintain a constant space dry-bulb air temperature and humidity. Sensible heat into the space causes its air temperature to rise while latent heat is associated with the rise of the moisture content in the space. The building design, internal equipment, occupants, and outdoor weather conditions may affect the cooling load in a building using different heat transfer mechanisms. The SI units are watts.