Heating, ventilation, and air conditioning (HVAC) is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality. HVAC system design is a subdiscipline of mechanical engineering, based on the principles of thermodynamics, fluid mechanics, and heat transfer. "Refrigeration" is sometimes added to the field's abbreviation as HVAC&R or HVACR, or "ventilation" is dropped, as in HACR.

A thermostat is a regulating device component which senses the temperature of a physical system and performs actions so that the system's temperature is maintained near a desired setpoint.

HVAC equipment needs a control system to regulate the operation of a heating and/or air conditioning system. Usually a sensing device is used to compare the actual state with a target state. Then the control system draws a conclusion what action has to be taken.

Heat recovery ventilation (HRV), also known as mechanical ventilation heat recovery (MVHR) or energy recovery ventilation (ERV), is a ventilation system that recovers energy by operating between two air sources at different temperatures. It is used to reduce the heating and cooling demands of buildings.

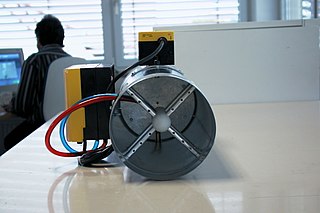

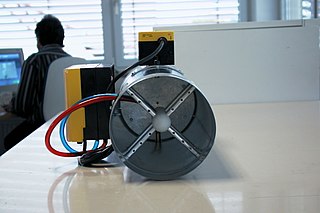

A damper is a valve or plate that stops or regulates the flow of air inside a duct, chimney, VAV box, air handler, or other air-handling equipment. A damper may be used to cut off central air conditioning to an unused room, or to regulate it for room-by-room temperature and climate control - for example, in the case of Volume Control Dampers. Its operation can be manual or automatic. Manual dampers are turned by a handle on the outside of a duct. Automatic dampers are used to regulate airflow constantly and are operated by electric or pneumatic motors, in turn controlled by a thermostat or building automation system. Automatic or motorized dampers may also be controlled by a solenoid, and the degree of air-flow calibrated, perhaps according to signals from the thermostat going to the actuator of the damper in order to modulate the flow of air-conditioned air in order to effect climate control.

Hydronics is the use of liquid water or gaseous water (steam) or a water solution as a heat-transfer medium in heating and cooling systems. The name differentiates such systems from oil and refrigerant systems.

An air handler, or air handling unit, is a device used to regulate and circulate air as part of a heating, ventilating, and air-conditioning (HVAC) system. An air handler is usually a large metal box containing a blower, furnace or A/C elements, filter racks or chambers, sound attenuators, and dampers. Air handlers usually connect to a ductwork ventilation system that distributes the conditioned air through the building and returns it to the AHU, sometimes exhausting air to the atmosphere and bringing in fresh air. Sometimes AHUs discharge (supply) and admit (return) air directly to and from the space served without ductwork

Variable air volume (VAV) is a type of heating, ventilating, and/or air-conditioning (HVAC) system. Unlike constant air volume (CAV) systems, which supply a constant airflow at a variable temperature, VAV systems vary the airflow at a constant or varying temperature. The advantages of VAV systems over constant-volume systems include more precise temperature control, reduced compressor wear, lower energy consumption by system fans, less fan noise, and additional passive dehumidification.

Ducts are conduits or passages used in heating, ventilation, and air conditioning (HVAC) to deliver and remove air. The needed airflows include, for example, supply air, return air, and exhaust air. Ducts commonly also deliver ventilation air as part of the supply air. As such, air ducts are one method of ensuring acceptable indoor air quality as well as thermal comfort.

The Air Movement and Control Association International, Inc. (AMCA) is an American trade body that sets standards for Heating, Ventilation and Air Conditioning (HVAC) equipment. It rates fan balance and vibration, aerodynamic performance, air density, speed and efficiency.

Founded in 1971 and headquartered in Gaithersburg, Maryland, USA; the National Environmental Balancing Bureau (NEBB) is an international association certifying firms and qualifying supervisors and technicians in the following disciplines: Testing, Adjusting, and Balancing (TAB) of HVAC systems; Building Systems Commissioning (BSC); Sound and Vibration Measurement (S&V); Retro-commissioning (RCX); Fumehood Testing (FHT); and Cleanroom Performance Testing (CPT). NEBB also establishes and maintains industry standards, procedures, and work specifications for these disciplines.

In construction, commissioning or commissioning process is an integrated, systematic process to ensure, through documented verification, that all building systems perform interactively according to the "Design Intent". The commissioning process establishes and documents the "Owner's Project Requirements (OPR)" criteria for system function, performance expectations, maintainability; verify and document compliance with these criteria throughout all phases of the project. Commissioning procedures require a collaborative team effort and 'should' begin during the pre-design or planning phase of the project, continue through the design and construction phases, initial occupancy phase, training of operations and maintenance (O&M) staff, and into occupancy.

Free cooling is an economical method of using low external air temperatures to assist in chilling water, which can then be used for industrial processes, or air conditioning systems. The chilled water can either be used immediately or be stored for the short- or long-term. When outdoor temperatures are lower relative to indoor temperatures, this system utilizes the cool outdoor air as a free cooling source. In this manner, the system replaces the chiller in traditional air conditioning systems while achieving the same cooling result. Such systems can be made for single buildings or district cooling networks.

HVAC is a major sub discipline of mechanical engineering. The goal of HVAC design is to balance indoor environmental comfort with other factors such as installation cost, ease of maintenance, and energy efficiency. The discipline of HVAC includes a large number of specialized terms and acronyms, many of which are summarized in this glossary.

Hydronic balancing, also called hydraulic balancing, is the process of optimizing the distribution of water in a building's hydronic heating or cooling system by equalizing the system pressure to provide the intended indoor climate at optimum energy efficiency and minimal operating cost.

Automatic balancing valves are utilised in central heating and cooling systems that rely on flow of water through the system. They use the latest flow technology to ensure that the design flow rate is achieved at all times irrespective of any pressure changes within the system.

A dedicated outdoor air system (DOAS) is a type of heating, ventilation and air-conditioning (HVAC) system that consists of two parallel systems: a dedicated system for delivering outdoor air ventilation that handles both the latent and sensible loads of conditioning the ventilation air, and a parallel system to handle the loads generated by indoor/process sources and those that pass through the building enclosure.

In building services engineering and HVAC, an air-mixing plenum is used for mixing air from different ductwork systems.

In air conditioning, an inverter compressor is a compressor that is operated with an inverter.

Ductwork airtightness can be defined as the resistance to inward or outward air leakage through the ductwork envelope. This air leakage is driven by differential pressures across the ductwork envelope due to the combined effects of stack and fan operation.