Concrete is a composite material composed of aggregate bonded together with a fluid cement that cures over time. Concrete is the second-most-used substance in the world after water, and is the most widely used building material. Its usage worldwide, ton for ton, is twice that of steel, wood, plastics, and aluminium combined.

Masonry is the craft of building a structure with brick, stone, or similar material, including mortar plastering which are often laid in, bound and pasted together by mortar. The term masonry can also refer to the building units themselves.

An earth shelter, also called an earth house, earth bermed house, or underground house, is a structure with earth (soil) against the walls, on the roof, or that is entirely buried underground.

Vermiculite is a hydrous phyllosilicate mineral which undergoes significant expansion when heated. Exfoliation occurs when the mineral is heated sufficiently; commercial furnaces can routinely produce this effect. Vermiculite forms by the weathering or hydrothermal alteration of biotite or phlogopite. Large commercial vermiculite mines exist in the United States, Russia, South Africa, China, and Brazil.

Mortar is a workable paste which hardens to bind building blocks such as stones, bricks, and concrete masonry units, to fill and seal the irregular gaps between them, spread the weight of them evenly, and sometimes to add decorative colors or patterns to masonry walls. In its broadest sense, mortar includes pitch, asphalt, and soft mud or clay, as those used between mud bricks, as well as cement mortar. The word "mortar" comes from Old French mortier, "builder's mortar, plaster; bowl for mixing." (13c.).

Plaster is a building material used for the protective or decorative coating of walls and ceilings and for moulding and casting decorative elements. In English, "plaster" usually means a material used for the interiors of buildings, while "render" commonly refers to external applications. The term stucco refers to plasterwork that is worked in some way to produce relief decoration, rather than flat surfaces.

Building material is material used for construction. Many naturally occurring substances, such as clay, rocks, sand, wood, and even twigs and leaves, have been used to construct buildings. Apart from naturally occurring materials, many man-made products are in use, some more and some less synthetic. The manufacturing of building materials is an established industry in many countries and the use of these materials is typically segmented into specific specialty trades, such as carpentry, insulation, plumbing, and roofing work. They provide the make-up of habitats and structures including homes.

Seismic retrofitting is the modification of existing structures to make them more resistant to seismic activity, ground motion, or soil failure due to earthquakes. With better understanding of seismic demand on structures and with recent experiences with large earthquakes near urban centers, the need of seismic retrofitting is well acknowledged. Prior to the introduction of modern seismic codes in the late 1960s for developed countries and late 1970s for many other parts of the world, many structures were designed without adequate detailing and reinforcement for seismic protection. In view of the imminent problem, various research work has been carried out. State-of-the-art technical guidelines for seismic assessment, retrofit and rehabilitation have been published around the world – such as the ASCE-SEI 41 and the New Zealand Society for Earthquake Engineering (NZSEE)'s guidelines. These codes must be regularly updated; the 1994 Northridge earthquake brought to light the brittleness of welded steel frames, for example.

This page is a list of construction topics.

Steel frame is a building technique with a "skeleton frame" of vertical steel columns and horizontal I-beams, constructed in a rectangular grid to support the floors, roof and walls of a building which are all attached to the frame. The development of this technique made the construction of the skyscraper possible.

Formwork is molds into which concrete or similar materials are either precast or cast-in-place. In the context of concrete construction, the falsework supports the shuttering molds. In specialty applications formwork may be permanently incorporated into the final structure, adding insulation or helping reinforce the finished structure.

Autoclaved aerated concrete (AAC) is a lightweight, precast, cellular concrete building material, eco-friendly, suitable for producing concrete-like blocks. It is composed of quartz sand, calcined gypsum, lime, portland cement, water and aluminium powder. AAC products are cured under heat and pressure in an autoclave. Developed in the mid-1920s, AAC provides insulation, fire, and mold-resistance. Forms include blocks, wall panels, floor and roof panels, cladding (façade) panels and lintels. It is also an insulator.

Structural steel is a category of steel used for making construction materials in a variety of shapes. Many structural steel shapes take the form of an elongated beam having a profile of a specific cross section. Structural steel shapes, sizes, chemical composition, mechanical properties such as strengths, storage practices, etc., are regulated by standards in most industrialized countries.

An intumescent is a substance that swells as a result of heat exposure, leading to an increase in volume and decrease in density. Intumescence refers to the process of swelling. Intumescent materials are typically used in passive fire protection and require listing, approval, and compliance in their installed configurations in order to comply with the national building codes and laws.

Passive fire protection (PFP) is components or systems of a building or structure that slows or impedes the spread of the effects of fire or smoke without system activation, and usually without movement. Examples of passive systems include floor-ceilings and roofs, fire doors, windows, and wall assemblies, fire-resistant coatings, and other fire and smoke control assemblies. Passive fire protection systems can include active components such as fire dampers.

A fire-resistance rating typically means the duration for which a passive fire protection system can withstand a standard fire resistance test. This can be quantified simply as a measure of time, or it may entail other criteria, involving evidence of functionality or fitness for purpose.

The history of structural engineering dates back to at least 2700 BC when the step pyramid for Pharaoh Djoser was built by Imhotep, the first architect in history known by name. Pyramids were the most common major structures built by ancient civilizations because it is a structural form which is inherently stable and can be almost infinitely scaled.

Concrete is produced in a variety of compositions, finishes and performance characteristics to meet a wide range of needs.

Concrete has relatively high compressive strength, but significantly lower tensile strength. The compressive strength is typically controlled with the ratio of water to cement when forming the concrete, and tensile strength is increased by additives, typically steel, to create reinforced concrete. In other words we can say concrete is made up of sand, ballast, cement and water.

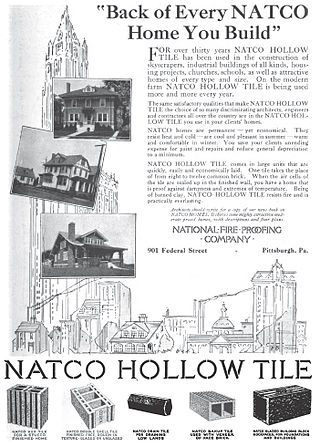

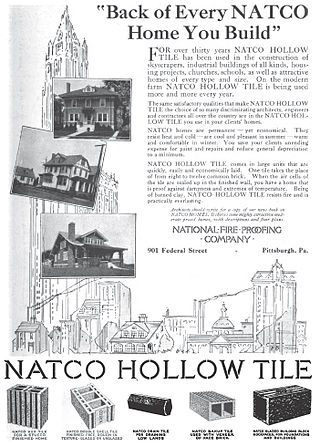

Structural clay tile describes a category of burned-clay building materials used to construct roofing, walls, and flooring for structural and non-structural purposes, especially in fireproofing applications. Also called building tile, structural terra cotta, hollow tile, saltillo tile, and clay block, the material is an extruded clay shape with substantial depth that allows it to be laid in the same manner as other clay or concrete masonry. In North America it was chiefly used during the late 19th and early 20th centuries, reaching peak popularity at the turn of the century and declining around the 1950s. Structural clay tile grew in popularity in the end of the nineteenth-century because it could be constructed faster, was lighter, and required simpler flat falsework than earlier brick vaulting construction. Each unit is generally made of clay or terra-cotta with hollow cavities, or cells, inside it. The colors of terracotta transform from gray to orange, red, yellow, and cream tones. This is due to an effect of the firing process which hardens the clay so it can be used for structural purposes. The material is commonly used in floor arches, fireproofing, partition walls, and furring. It continues to be used in Europe to build fire-resistant walls and partitions. In North America the material has largely been replaced by concrete masonry units.