Conversion of units is the conversion of the unit of measurement in which a quantity is expressed, typically through a multiplicative conversion factor that changes the unit without changing the quantity. This is also often loosely taken to include replacement of a quantity with a corresponding quantity that describes the same physical property.

Horsepower (hp) is a unit of measurement of power, or the rate at which work is done, usually in reference to the output of engines or motors. There are many different standards and types of horsepower. Two common definitions used today are the imperial horsepower as in "hp" or "bhp" which is about 745.7 watts, and the metric horsepower as in "cv" or "PS" which is approximately 735.5 watts.

A fire sprinkler system is an active fire protection method, consisting of a water supply system providing adequate pressure and flowrate to a water distribution piping system, to which fire sprinklers are connected. Although initially used only in factories and large commercial buildings, systems for homes and small buildings are now available at a cost-effective price.

Flow measurement is the quantification of bulk fluid movement. Flow can be measured using devices called flowmeters in various ways. The common types of flowmeters with industrial applications are listed below:

In fluid dynamics, the Darcy–Weisbach equation is an empirical equation that relates the head loss, or pressure loss, due to friction along a given length of pipe to the average velocity of the fluid flow for an incompressible fluid. The equation is named after Henry Darcy and Julius Weisbach. Currently, there is no formula more accurate or universally applicable than the Darcy-Weisbach supplemented by the Moody diagram or Colebrook equation.

In physics and engineering, in particular fluid dynamics, the volumetric flow rate is the volume of fluid which passes per unit time; usually it is represented by the symbol Q. It contrasts with mass flow rate, which is the other main type of fluid flow rate. In most contexts a mention of rate of fluid flow is likely to refer to the volumetric rate. In hydrometry, the volumetric flow rate is known as discharge.

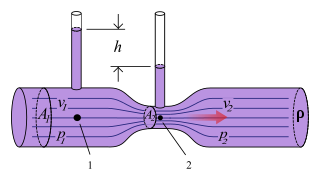

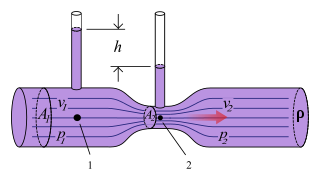

The Venturi effect is the reduction in fluid pressure that results when a moving fluid speeds up as it flows through a constricted section of a pipe. The Venturi effect is named after its discoverer, the 18th-century Italian physicist Giovanni Battista Venturi.

A blower door is a machine used to perform a building air leakage test. It can also be used to measure airflow between building zones, to test ductwork airtightness and to help physically locate air leakage sites in the building envelope.

An orifice plate is a device used for measuring flow rate, for reducing pressure or for restricting flow.

The Fanning friction factor is a dimensionless number used as a local parameter in continuum mechanics calculations. It is defined as the ratio between the local shear stress and the local flow kinetic energy density:

The Hazen–Williams equation is an empirical relationship that relates the flow of water in a pipe with the physical properties of the pipe and the pressure drop caused by friction. It is used in the design of water pipe systems such as fire sprinkler systems, water supply networks, and irrigation systems. It is named after Allen Hazen and Gardner Stewart Williams.

Accidental release source terms are the mathematical equations that quantify the flow rate at which accidental releases of liquid or gaseous pollutants into the ambient environment which can occur at industrial facilities such as petroleum refineries, petrochemical plants, natural gas processing plants, oil and gas transportation pipelines, chemical plants, and many other industrial activities. Governmental regulations in many countries require that the probability of such accidental releases be analyzed and their quantitative impact upon the environment and human health be determined so that mitigating steps can be planned and implemented.

Specific speedNs, is used to characterize turbomachinery speed. Common commercial and industrial practices use dimensioned versions which are of equal utility. Specific speed is most commonly used in pump applications to define the suction specific speed —a quasi non-dimensional number that categorizes pump impellers as to their type and proportions. In Imperial units it is defined as the speed in revolutions per minute at which a geometrically similar impeller would operate if it were of such a size as to deliver one gallon per minute against one foot of hydraulic head. In metric units flow may be in l/s or m3/s and head in m, and care must be taken to state the units used.

The flow coefficient of a device is a relative measure of its efficiency at allowing fluid flow. It describes the relationship between the pressure drop across an orifice valve or other assembly and the corresponding flow rate.

Minute ventilation is the volume of gas inhaled or exhaled from a person's lungs per minute. It is an important parameter in respiratory medicine due to its relationship with blood carbon dioxide levels. It can be measured with devices such as a Wright respirometer or can be calculated from other known respiratory parameters. Although minute volume can be viewed as a unit of volume, it is usually treated in practice as a flow rate. Typical units involved are 0.5 L × 12 breaths/min = 6 L/min.

Airwatt or air watt is a unit of measurement that represents the true suction power of vacuum cleaners. It is calculated by multiplying the airflow by the suction pressure. This measurement reflects the energy per unit time of the air flowing through the vacuum's opening, which correlates to the electrical energy (wattage) supplied through the power cable.

In non ideal fluid dynamics, the Hagen–Poiseuille equation, also known as the Hagen–Poiseuille law, Poiseuille law or Poiseuille equation, is a physical law that gives the pressure drop in an incompressible and Newtonian fluid in laminar flow flowing through a long cylindrical pipe of constant cross section. It can be successfully applied to air flow in lung alveoli, or the flow through a drinking straw or through a hypodermic needle. It was experimentally derived independently by Jean Léonard Marie Poiseuille in 1838 and Gotthilf Heinrich Ludwig Hagen, and published by Hagen in 1839 and then by Poiseuille in 1840–41 and 1846. The theoretical justification of the Poiseuille law was given by George Stokes in 1845.

In a nozzle or other constriction, the discharge coefficient is the ratio of the actual discharge to the ideal discharge, i.e., the ratio of the mass flow rate at the discharge end of the nozzle to that of an ideal nozzle which expands an identical working fluid from the same initial conditions to the same exit pressures.

A spray is a dynamic collection of drops dispersed in a gas. The process of forming a spray is known as atomization. A spray nozzle is the device used to generate a spray. The two main uses of sprays are to distribute material over a cross-section and to generate liquid surface area. There are thousands of applications in which sprays allow material to be used most efficiently. The spray characteristics required must be understood in order to select the most appropriate technology, optimal device and size.

Standard cubic centimeters per minute (SCCM) is a unit used to quantify the flow rate of a fluid. 1 SCCM is identical to 1 cm³STP/min. Another expression of it would be Nml/min. These standard conditions vary according to different regulatory bodies. One example of standard conditions for the calculation of SCCM is = 0 °C and = 1.01 bar and a unity compressibility factor = 1. This example is for the semi-conductor-manufacturing industry.