An autonomous building is a building designed to be operated independently from infrastructural support services such as the electric power grid, gas grid, municipal water systems, sewage treatment systems, storm drains, communication services, and in some cases, public roads.

A boiler is a closed vessel in which fluid is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking, and sanitation.

A furnace, referred to as a heater or boiler in British English, is an appliance used to generate heat for all or part of a building. Furnaces are mostly used as a major component of a central heating system. Furnaces are permanently installed to provide heat to an interior space through intermediary fluid movement, which may be air, steam, or hot water. Heating appliances that use steam or hot water as the fluid are normally referred to as a residential steam boilers or residential hot water boilers. The most common fuel source for modern furnaces in North America and much of Europe is natural gas; other common fuel sources include LPG, fuel oil, wood and in rare cases coal. In some areas electrical resistance heating is used, especially where the cost of electricity is low or the primary purpose is for air conditioning. Modern high-efficiency furnaces can be up to 98% efficient and operate without a chimney, with a typical gas furnace being about 80% efficient. Waste gas and heat are mechanically ventilated through either metal flue pipes or polyvinyl chloride (PVC) pipes that can be vented through the side or roof of the structure. Fuel efficiency in a gas furnace is measured in AFUE.

Solar thermal energy (STE) is a form of energy and a technology for harnessing solar energy to generate thermal energy for use in industry, and in the residential and commercial sectors. Solar thermal collectors are classified by the United States Energy Information Administration as low-, medium-, or high-temperature collectors. Low-temperature collectors are generally unglazed and used to heat swimming pools or to heat ventilation air. Medium-temperature collectors are also usually flat plates but are used for heating water or air for residential and commercial use.

Water heating is a heat transfer process that uses an energy source to heat water above its initial temperature. Typical domestic uses of hot water include cooking, cleaning, bathing, and space heating. In industry, hot water and water heated to steam have many uses.

Solar water heating (SWH) is heating water by sunlight, using a solar thermal collector. A variety of configurations are available at varying cost to provide solutions in different climates and latitudes. SWHs are widely used for residential and some industrial applications.

A combined cycle power plant is an assembly of heat engines that work in tandem from the same source of heat, converting it into mechanical energy. On land, when used to make electricity the most common type is called a combined cycle gas turbine (CCGT) plant, which is a kind of gas-fired power plant. The same principle is also used for marine propulsion, where it is called a combined gas and steam (COGAS) plant. Combining two or more thermodynamic cycles improves overall efficiency, which reduces fuel costs.

A solar thermal collector collects heat by absorbing sunlight. The term "solar collector" commonly refers to a device for solar hot water heating, but may refer to large power generating installations such as solar parabolic troughs and solar towers or non-water heating devices such as solar cookers or solar air heaters.

A central heating system provides warmth to a number of spaces within a building from one main source of heat. It is a component of heating, ventilation, and air conditioning systems, which can both cool and warm interior spaces.

Thermal energy storage (TES) is the storage of thermal energy for later reuse. Employing widely different technologies, it allows surplus thermal energy to be stored for hours, days, or months. Scale both of storage and use vary from small to large – from individual processes to district, town, or region. Usage examples are the balancing of energy demand between daytime and nighttime, storing summer heat for winter heating, or winter cold for summer cooling. Storage media include water or ice-slush tanks, masses of native earth or bedrock accessed with heat exchangers by means of boreholes, deep aquifers contained between impermeable strata; shallow, lined pits filled with gravel and water and insulated at the top, as well as eutectic solutions and phase-change materials.

Electric heating is a process in which electrical energy is converted directly to heat energy. Common applications include space heating, cooking, water heating and industrial processes. An electric heater is an electrical device that converts an electric current into heat. The heating element inside every electric heater is an electrical resistor, and works on the principle of Joule heating: an electric current passing through a resistor will convert that electrical energy into heat energy. Most modern electric heating devices use nichrome wire as the active element; the heating element, depicted on the right, uses nichrome wire supported by ceramic insulators.

Condensing boilers are water heaters typically used for heating systems that are fueled by gas or oil. When operated in the correct circumstances, a heating system can achieve high efficiency by condensing water vapour found in the exhaust gases in a heat exchanger to preheat the circulating water. This recovers the latent heat of vaporisation, which would otherwise have been wasted. The condensate is sent to a drain. In many countries, the use of condensing boilers is compulsory or encouraged with financial incentives.

Renewable heat is an application of renewable energy referring to the generation of heat from renewable sources; for example, feeding radiators with water warmed by focused solar radiation rather than by a fossil fuel boiler. Renewable heat technologies include renewable biofuels, solar heating, geothermal heating, heat pumps and heat exchangers. Insulation is almost always an important factor in how renewable heating is implemented.

A heater core is a radiator-like device used in heating the cabin of a vehicle. Hot coolant from the vehicle's engine is passed through a winding tube of the core, a heat exchanger between coolant and cabin air. Fins attached to the core tubes serve to increase surface area for heat transfer to air that is forced past them by a fan, thereby heating the passenger compartment.

A solar combisystem provides both solar space heating and cooling as well as hot water from a common array of solar thermal collectors, usually backed up by an auxiliary non-solar heat source.

The Drake Landing Solar Community (DLSC) is a planned community in Okotoks, Alberta, Canada, equipped with a central solar heating system and other energy efficient technologies. This heating system is the first of its kind in North America, although much larger systems have been built in northern Europe. The 52 homes in the community are heated with a solar district heating system that is charged with heat originating from solar collectors on the garage roofs and is enabled for year-round heating by underground seasonal thermal energy storage (STES).

Solar hot water refers to water heated by solar energy, a renewable energy source derived from the sun. This process involves thermal collectors, often called solar panels, which absorb solar energy to increase the temperature of the water. The heated water is then stored in a reservoir tank for future use. Solar hot water systems are utilised for a variety of purposes, including domestic and commercial water heating, contributing to heating and cooling systems, and providing process heat for industrial applications.

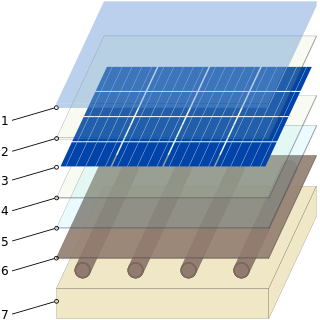

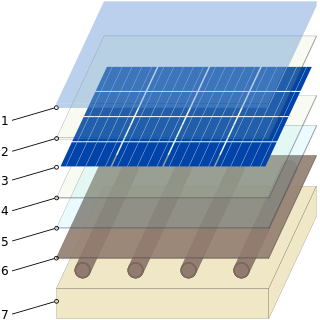

Photovoltaic thermal collectors, typically abbreviated as PVT collectors and also known as hybrid solar collectors, photovoltaic thermal solar collectors, PV/T collectors or solar cogeneration systems, are power generation technologies that convert solar radiation into usable thermal and electrical energy. PVT collectors combine photovoltaic solar cells, which convert sunlight into electricity, with a solar thermal collector, which transfers the otherwise unused waste heat from the PV module to a heat transfer fluid. By combining electricity and heat generation within the same component, these technologies can reach a higher overall efficiency than solar photovoltaic (PV) or solar thermal (T) alone.

A hot water storage tank is a water tank used for storing hot water for space heating or domestic use.

Tankless water heaters — also called instantaneous, continuous flow, inline, flash, on-demand, or instant-on water heaters — are water heaters that instantly heat water as it flows through the device, and do not retain any water internally except for what is in the heat exchanger coil unless the unit is equipped with an internal buffer tank. Copper heat exchangers are preferred in these units because of their high thermal conductivity and ease of fabrication. However, copper heat exchangers are more susceptible to scale buildup than stainless steel heat exchangers.