Related Research Articles

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments, threads, different fabric types, etc. At first, the word "textiles" only referred to woven fabrics. However, weaving is not the only manufacturing method, and many other methods were later developed to form textile structures based on their intended use. Knitting and non-woven are other popular types of fabric manufacturing. In the contemporary world, textiles satisfy the material needs for versatile applications, from simple daily clothing to bulletproof jackets, spacesuits, and doctor's gowns.

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal threads are called the warp and the lateral threads are the weft, woof, or filling. The method in which these threads are interwoven affects the characteristics of the cloth. Cloth is usually woven on a loom, a device that holds the warp threads in place while filling threads are woven through them. A fabric band that meets this definition of cloth can also be made using other methods, including tablet weaving, back strap loom, or other techniques that can be done without looms.

Yarn is a long continuous length of interlocked fibres, used in sewing, crocheting, knitting, weaving, embroidery, ropemaking, and the production of textiles. Thread is a type of yarn intended for sewing by hand or machine. Modern manufactured sewing threads may be finished with wax or other lubricants to withstand the stresses involved in sewing. Embroidery threads are yarns specifically designed for needlework. Yarn can be made of a number of natural or synthetic materials, and comes in a variety of colors and thicknesses. Although yarn may be dyed different colours, most yarns are solid coloured with a uniform hue.

Linen is a textile made from the fibers of the flax plant.

Velvet is a type of woven tufted fabric in which the cut threads are evenly distributed, with a short pile, giving it a distinctive soft feel. By extension, the word velvety means "smooth like velvet". In the past, velvet was typically made from silk. Today, velvet can be made from linen, cotton, wool and synthetic fibers.

A raincoat is a waterproof or water-resistant garment worn on the upper body to shield the wearer from rain. The term rain jacket is sometimes used to refer to raincoats with long sleeves that are waist-length. A rain jacket may be combined with a pair of rain pants to make a rainsuit. Rain clothing may also be in one piece, like a boilersuit. Raincoats, like rain ponchos, offer the wearer hands-free protection from the rain and elements; unlike the umbrella.

Gabardine is a durable twill worsted wool, a tightly woven fabric originally waterproof and used to make suits, overcoats, trousers, uniforms, windbreakers, outerwear and other garments.

Flannel is a soft woven fabric, of various fineness. Flannel was originally made from carded wool or worsted yarn, but is now often made from either wool, cotton, or synthetic fiber. Flannel is commonly used to make tartan clothing, blankets, bed sheets, and sleepwear.

Dyeing is the application of dyes or pigments on textile materials such as fibers, yarns, and fabrics with the goal of achieving color with desired color fastness. Dyeing is normally done in a special solution containing dyes and particular chemical material. Dye molecules are fixed to the fiber by absorption, diffusion, or bonding with temperature and time being key controlling factors. The bond between dye molecule and fiber may be strong or weak, depending on the dye used. Dyeing and printing are different applications; in printing, color is applied to a localized area with desired patterns. In dyeing, it is applied to the entire textile.

Damask is a reversible patterned fabric of silk, wool, linen, cotton, or synthetic fibers, with a pattern formed by weaving. Damasks are woven with one warp yarn and one weft yarn, usually with the pattern in warp-faced satin weave and the ground in weft-faced or sateen weave. Twill damasks include a twill-woven ground or pattern.

A bathrobe, also known as a housecoat or a dressing gown, is a loose-fitting outer garment worn by people, often after washing the body or around a pool. A bathrobe is considered to be very informal clothing, and is not worn with everyday clothes.

Crêpe, also spelled crepe or crape is a silk, wool, or synthetic fiber fabric with a distinctively crisp and crimped appearance. The term "crape" typically refers to a form of the fabric associated specifically with mourning. Crêpe was also historically called "crespe" or "crisp".

The manufacture of textiles is one of the oldest of human technologies. To make textiles, the first requirement is a source of fiber from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving, which turns yarn into cloth. The machine used for weaving is the loom. For decoration, the process of colouring yarn or the finished material is dyeing. For more information of the various steps, see textile manufacturing.

Grosgrain is a type of fabric or ribbon defined by the fact that its weft is heavier than its warp, creating prominent transverse ribs. Grosgrain is a plain weave corded fabric, with heavier cords than poplin but lighter than faille, and is known for being a firm, close-woven, fine-corded fabric. Grosgrain has a dull appearance, with little luster in comparison to many fabric weaves, such as satin, often used for ribbons; however, it is comparatively very strong. Grosgrain fabric is most commonly available in black, but grosgrain ribbon comes in a large variety of colors and patterns. The ribbon is very similar to Petersham ribbon in its appearance, but it does not have the ability to follow the curves of a surface or edge the way that the latter does.

A staple fiber is a textile fiber of discrete length. The opposite is a filament fiber, which comes in continuous lengths. Staple length is a characteristic fiber length of a sample of staple fibers. It is an essential criterion in yarn spinning, and aids in cohesion and twisting. Compared to synthetic fibers, natural fibers tend to have different and shorter lengths. The quality of natural fibers like cotton is categorized on staple length such as short, medium, long-staple, and extra long. Gossypium barbadense, one of several cotton species, produces extra-long staple fibers. The staple fibers may be obtained from natural and synthetic sources. In the case of synthetics and blends, the filament yarns are cut to a predetermined length.

Novelty yarns include a wide variety of yarns made with unusual features, structure or fiber composition such as slubs, inclusions, metallic or synthetic fibers, laddering and varying thickness introduced during production. Some linens, wools to be woven into tweed, and the uneven filaments of some types of silk are allowed to retain their normal irregularities, producing the characteristic uneven surface of the finished fabric. Man-made fibres, which can be modified during production, are especially adaptable for special effects such as crimping and texturizing.

In textile manufacturing, finishing refers to the processes that convert the woven or knitted cloth into a usable material and more specifically to any process performed after dyeing the yarn or fabric to improve the look, performance, or "hand" (feel) of the finish textile or clothing. The precise meaning depends on context.

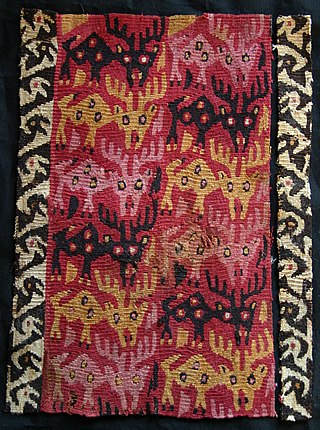

Textile arts of indigenous peoples of the Americas are decorative, utilitarian, ceremonial, or conceptual artworks made from plant, animal, or synthetic fibers by native peoples of both North and South America.

Wet Processing Engineering is one of the major streams in Textile Engineering or Textile manufacturing which refers to the engineering of textile chemical processes and associated applied science. The other three streams in textile engineering are yarn engineering, fabric engineering, and apparel engineering. The processes of this stream are involved or carried out in an aqueous stage. Hence, it is called a wet process which usually covers pre-treatment, dyeing, printing, and finishing.

A blend is a mixture of two or more fibers. In yarn spinning, different compositions, lengths, diameters, or colors may be combined to create a blend. Blended textiles are fabrics or yarns produced with a combination of two or more types of different fibers, or yarns to obtain desired traits and aesthetics. Blending is possible at various stages of textile manufacturing. The term, blend, refers to spun fibers or a fabric composed of such fibers. There are several synonymous terms: a combination yarn is made up of two strands of different fibers twisted together to form a ply; a mixture or mixed cloth refers to blended cloths in which different types of yarns are used in warp and weft sides.

References

- 1 2 "the online dictionary/thesaurus/satinets". the online dictionary. Retrieved 2007-11-10.

- ↑ Marvin, AP (1879). History of Worcester County, Massachusetts, Embracing a Comprehensive History of the County from its earliest beginnings to the present time; Vol. lI. Boston, MA: CF Jewitt and Company. p. 146.