| Thermodynamics |

|---|

|

This timeline of heat engine technology describes how heat engines have been known since antiquity but have been made into increasingly useful devices since the 17th century as a better understanding of the processes involved was gained. A heat engine is any system that converts heat to mechanical energy, which can then be used to do mechanical work.They continue to be developed today.

Contents

- Pre-17th century

- 17th century

- 18th century

- 19th century

- 20th century

- 21st century

- See also

- References

- Citations

- Sources

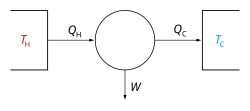

In engineering and thermodynamics, a heat engine performs the conversion of heat energy to mechanical work by exploiting the temperature gradient between a hot "source" and a cold "sink". Heat is transferred to the sink from the source, and in this process some of the heat is converted into work.

A heat pump is a heat engine run in reverse. Work is used to create a heat differential. The timeline includes devices classed as both engines and pumps, as well as identifying significant leaps in human understanding.