Crochet is a process of creating textiles by using a crochet hook to interlock loops of yarn, thread, or strands of other materials. The name is derived from the French term crochet, which means 'hook'. Hooks can be made from different materials, sizes, and types. The key difference between crochet and knitting, beyond the implements used for their production, is that each stitch in crochet is completed before you begin the next one, while knitting keeps many stitches open at a time. Some variant forms of crochet, such as Tunisian crochet and Broomstick lace, do keep multiple crochet stitches open at a time.

Knitting is a method for production of textile fabrics by interlacing yarn loops with loops of the same or other yarns. It is used to create many types of garments. Knitting may be done by hand or by machine.

A knitting needle or knitting pin is a tool in hand-knitting to produce knitted fabrics. They generally have a long shaft and taper at their end, but they are not nearly as sharp as sewing needles. Their purpose is two-fold. The long shaft holds the active (unsecured) stitches of the fabric, to prevent them from unravelling, whereas the tapered ends are used to form new stitches. Most commonly, a new stitch is formed by inserting the tapered end through an active stitch, catching a loop of fresh yarn and drawing it through the stitch; this secures the initial stitch and forms a new active stitch in its place. In specialized forms of knitting the needle may be passed between active stitches being held on another needle, or indeed between/through inactive stitches that have been knit previously.

Knitting is the process of using two or more needles to pull and loop yarn into a series of interconnected loops in order to create a finished garment or some other type of fabric. The word is derived from knot, thought to originate from the Dutch verb knutten, which is similar to the Old English cnyttan, "to knot". Its origins lie in the basic human need for clothing for protection against the elements. More recently, hand knitting has become less a necessary skill and more of a hobby.

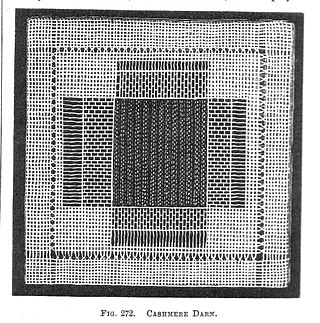

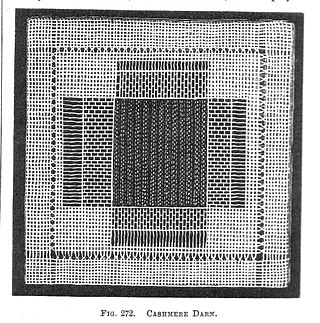

Darning is a sewing technique for repairing holes or worn areas in fabric or knitting using needle and thread alone. It is often done by hand, but using a sewing machine is also possible. Hand darning employs the darning stitch, a simple running stitch in which the thread is "woven" in rows along the grain of the fabric, with the stitcher reversing direction at the end of each row, and then filling in the framework thus created, as if weaving. Darning is a traditional method for repairing fabric damage or holes that do not run along a seam, and where patching is impractical or would create discomfort for the wearer, such as on the heel of a sock.

Piqué, or marcella, is a weaving style normally used with cotton yarn which is characterized by raised parallel cords or geometric designs in the fabric. Piqué fabrics vary from semi-sheer dimity to heavy weight waffle cloth. Twilled cotton and corded cotton are close relatives.

The term "gauge" is used in knitting to describe the fineness size of knitting machines. It is used in both hand knitting and machine knitting. The phrase in both instances refers to the number of stitches per inch rather than the size of the finished article of clothing. The gauge is calculated by counting the stitches or needles across a number of inches, then dividing by the sample's width in inches.

Combined knitting or combination knitting is a knitting method that combines elements of Eastern-style knitting with the Western techniques. The name was suggested by Mary Thomas in her 1938 book "Mary Thomas's Knitting Book", where she described the method as "..the better way to work in Flat Knitting. The resulting fabric is more even and closer in construction." By wrapping the yarn the opposite way while purling, the knitter changes the orientation of the resulting loops; then the next row's knit stitches can be formed by inserting the needle through the back leg, rather than through the front leg, without twisting the stitch. This method is suitable for all knitted fabrics from the basic Stockinette stitch, to any other technique, such as Fair Isle, circular knitting, or lace knitting.

A knitting machine is a device used to create knitted fabrics in a semi or fully automated fashion. There are numerous types of knitting machines, ranging from simple spool or board templates with no moving parts to highly complex mechanisms controlled by electronics. All, however, produce various types of knitted fabrics, usually either flat or tubular, and of varying degrees of complexity. Pattern stitches can be selected by hand manipulation of the needles, push-buttons and dials, mechanical punch cards, or electronic pattern reading devices and computers.

Lace knitting is a style of knitting characterized by stable holes in the fabric arranged with consideration of aesthetic value. Lace is sometimes considered the pinnacle of knitting, because of its complexity and because woven fabrics cannot easily be made to have holes. Famous examples include the Orenburg shawl and the wedding ring shawl of Shetland knitting, a shawl so fine that it could be drawn through a wedding ring. Shetland knitted lace became extremely popular in Victorian England when Queen Victoria became a Shetland lace enthusiast. Her enthusiasm resulted i.a. in her choosing knitted lacework for presents; e.g. when in ca. 1897 the Queen gave a lace shawl as a present to American abolitionist Harriet Tubman. From there, knitting patterns for the shawls were printed in English women's magazines where they were copied in Iceland with single ply wool.

In knitting, an increase is the creation of one or more new stitches, which may be done by various methods that create distinctive effects in the fabric. Most knitting increases either lean towards the left or the right.

Warp knitting is defined as a loop-forming process in which the yarn is fed into the knitting zone, parallel to the fabric selvage. It forms vertical loops in one course and then moves diagonally to knit the next course. Thus the yarns zigzag from side to side along the length of the fabric. Each stitch in a course is made by many different yarns. Each stitch in one wale is made by several different yarns.

Knitted fabric is a textile that results from knitting, the process of inter-looping of yarns or inter-meshing of loops. Its properties are distinct from woven fabric in that it is more flexible and can be more readily constructed into smaller pieces, making it ideal for socks and hats.

The manufacture of textiles is one of the oldest of human technologies. To make textiles, the first requirement is a source of fiber from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving, with color and patterns, which turns it into cloth. The machine used for weaving is the loom. For decoration, the process of coloring yarn or the finished material is dyeing. For more information of the various steps, see textile manufacturing.

Hand knitting is a form of knitting, in which the knitted fabric is produced by hand using needles.

Ottoman is a widthways-ribbed textile with pronounced, raised 'ribs' along its wale and course. Similar to grosgrain, Ottoman is known as a corded fabric, using a thicker yarn in the course rather than the wale to create raised stripes running across the width of the fabric.

Jersey is a knit fabric used predominantly for clothing manufacture. It was originally made of wool, but is now made of wool, cotton and synthetic fibers.

Textile manufacturing is one of the oldest human activities. The oldest known textiles date back to about 5000 B.C. In order to make textiles, the first requirement is a source of fibre from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving to create cloth. The machine used for weaving is the loom. Cloth is finished by what are described as wet process to become fabric. The fabric may be dyed, printed or decorated by embroidering with coloured yarns.

Sewing is the craft of fastening or attaching objects using stitches made with needle and thread. Sewing is one of the oldest of the textile arts, arising in the Paleolithic Era. Although usually associated with clothing and household linens, sewing is used in a variety of crafts and industries, including shoemaking, upholstery, sailmaking, bookbinding and the manufacturing of some kinds of sporting goods. Sewing is the fundamental process underlying a variety of textile arts and crafts, including embroidery, tapestry, quilting, appliqué and patchwork.

Ponte is a thick, double knit fabric design produced on double jersey knitting machines. It is one of the firm, stable structures of knits with a subtle sheen. This fabric is heavier and thicker than a regular jersey. As with most of the other double knit designs, Ponte is reversible. The fabric is also known as ''Ponte di Roma.''