In physics, cryogenics is the production and behaviour of materials at very low temperatures.

Refrigeration is any of various types of cooling of a space, substance, or system to lower and/or maintain its temperature below the ambient one. Refrigeration is an artificial, or human-made, cooling method.

The following is a timeline of low-temperature technology and cryogenic technology. It also lists important milestones in thermometry, thermodynamics, statistical physics and calorimetry, that were crucial in development of low temperature systems.

A cryopump or a "cryogenic pump" is a vacuum pump that traps gases and vapours by condensing them on a cold surface, but are only effective on some gases. The effectiveness depends on the freezing and boiling points of the gas relative to the cryopump's temperature. They are sometimes used to block particular contaminants, for example in front of a diffusion pump to trap backstreaming oil, or in front of a McLeod gauge to keep out water. In this function, they are called a cryotrap, waterpump or cold trap, even though the physical mechanism is the same as for a cryopump.

Magnetic refrigeration is a cooling technology based on the magnetocaloric effect. This technique can be used to attain extremely low temperatures, as well as the ranges used in common refrigerators.

A 3He/4He dilution refrigerator is a cryogenic device that provides continuous cooling to temperatures as low as 2 mK, with no moving parts in the low-temperature region. The cooling power is provided by the heat of mixing of the helium-3 and helium-4 isotopes.

A superconducting magnet is an electromagnet made from coils of superconducting wire. They must be cooled to cryogenic temperatures during operation. In its superconducting state the wire has no electrical resistance and therefore can conduct much larger electric currents than ordinary wire, creating intense magnetic fields. Superconducting magnets can produce stronger magnetic fields than all but the strongest non-superconducting electromagnets, and large superconducting magnets can be cheaper to operate because no energy is dissipated as heat in the windings. They are used in MRI instruments in hospitals, and in scientific equipment such as NMR spectrometers, mass spectrometers, fusion reactors and particle accelerators. They are also used for levitation, guidance and propulsion in a magnetic levitation (maglev) railway system being constructed in Japan.

Thermoacoustics is the interaction between temperature, density and pressure variations of acoustic waves. Thermoacoustic heat engines can readily be driven using solar energy or waste heat and they can be controlled using proportional control. They can use heat available at low temperatures which makes it ideal for heat recovery and low power applications. The components included in thermoacoustic engines are usually very simple compared to conventional engines. The device can easily be controlled and maintained.

A refrigerator designed to reach cryogenic temperatures is often called a cryocooler. The term is most often used for smaller systems, typically table-top size, with input powers less than about 20 kW. Some can have input powers as low as 2–3 W. Large systems, such as those used for cooling the superconducting magnets in particle accelerators are more often called cryogenic refrigerators. Their input powers can be as high as 1 MW. In most cases cryocoolers use a cryogenic fluid as the working substance and employ moving parts to cycle the fluid around a thermodynamic cycle. The fluid is typically compressed at room temperature, precooled in a heat exchanger, then expanded at some low temperature. The returning low-pressure fluid passes through the heat exchanger to precool the high-pressure fluid before entering the compressor intake. The cycle is then repeated.

A cryostat is a device used to maintain low cryogenic temperatures of samples or devices mounted within the cryostat. Low temperatures may be maintained within a cryostat by using various refrigeration methods, most commonly using cryogenic fluid bath such as liquid helium. Hence it is usually assembled into a vessel, similar in construction to a vacuum flask or Dewar. Cryostats have numerous applications within science, engineering, and medicine.

A refrigerator, commonly fridge, is a commercial and home appliance consisting of a thermally insulated compartment and a heat pump that transfers heat from its inside to its external environment so that its inside is cooled to a temperature below the room temperature. Refrigeration is an essential food storage technique around the world. The low temperature reduces the reproduction rate of bacteria, so the refrigerator lowers the rate of spoilage. A refrigerator maintains a temperature a few degrees above the freezing point of water. The optimal temperature range for perishable food storage is 3 to 5 °C. A freezer is a specialized refrigerator, or portion of a refrigerator, that maintains its contents’ temperature below the freezing point of water. The refrigerator replaced the icebox, which had been a common household appliance for almost a century and a half. The United States Food and Drug Administration recommends that the refrigerator be kept at or below 4 °C (40 °F) and that the freezer be regulated at −18 °C (0 °F).

An absorption refrigerator is a refrigerator that uses a heat source to provide the energy needed to drive the cooling process. Solar energy, burning a fossil fuel, waste heat from factories, and district heating systems are examples of convenient heat sources that can be used. An absorption refrigerator uses two coolants: the first coolant performs evaporative cooling and then is absorbed into the second coolant; heat is needed to reset the two coolants to their initial states. Absorption refrigerators are commonly used in recreational vehicles (RVs), campers, and caravans because the heat required to power them can be provided by a propane fuel burner, by a low-voltage DC electric heater or by a mains-powered electric heater. Absorption refrigerators can also be used to air-condition buildings using the waste heat from a gas turbine or water heater in the building. Using waste heat from a gas turbine makes the turbine very efficient because it first produces electricity, then hot water, and finally, air-conditioning—trigeneration.

Economizers, or economisers (UK), are mechanical devices intended to reduce energy consumption, or to perform useful function such as preheating a fluid. The term economizer is used for other purposes as well. Boiler, power plant, heating, refrigeration, ventilating, and air conditioning (HVAC) may all use economizers. In simple terms, an economizer is a heat exchanger.

Thermodynamic heat pump cycles or refrigeration cycles are the conceptual and mathematical models for heat pump, air conditioning and refrigeration systems. A heat pump is a mechanical system that transmits heat from one location at a certain temperature to another location at a higher temperature. Thus a heat pump may be thought of as a "heater" if the objective is to warm the heat sink, or a "refrigerator" or “cooler” if the objective is to cool the heat source. The operating principles in both cases are the same; energy is used to move heat from a colder place to a warmer place.

The Hampson–Linde cycle is a process for the liquefaction of gases, especially for air separation. William Hampson and Carl von Linde independently filed for patents of the cycle in 1895: Hampson on 23 May 1895 and Linde on 5 June 1895.

Regenerative cooling is a method of cooling gases in which compressed gas is cooled by allowing it to expand and thereby take heat from the surroundings. The cooled expanded gas then passes through a heat exchanger where it cools the incoming compressed gas.

Applications of the Stirling engine range from mechanical propulsion to heating and cooling to electrical generation systems. A Stirling engine is a heat engine operating by cyclic compression and expansion of air or other gas, the "working fluid", at different temperature levels such that there is a net conversion of heat to mechanical work. The Stirling cycle heat engine can also be driven in reverse, using a mechanical energy input to drive heat transfer in a reversed direction.

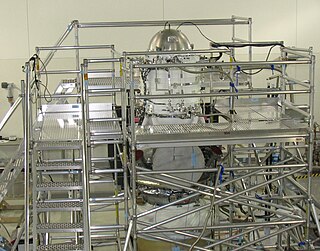

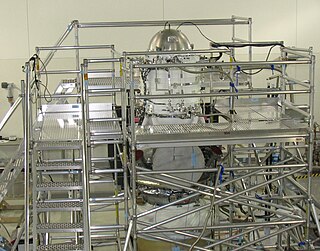

MIRI, or the Mid-Infrared Instrument, is an instrument on the James Webb Space Telescope. MIRI is a camera and a spectrograph that observes mid to long infrared radiation from 5 to 28 microns. It also has coronagraphs, especially for observing exoplanets. Whereas most of the other instruments on Webb can see from the start of near infrared, or even as short as orange visible light, MIRI can see longer wavelength light.

A cascade refrigeration cycle is a multi-stage thermodynamic cycle. An example two-stage process is shown at right. The cascade cycle is often employed for devices such as ULT freezers.

Michael Petach was an American engineer who made contributions in the fields of cryogenics and thermoacoustics in developing systems for space applications. He worked as an engineer for Northrop Grumman. His notable work revolved around developing cryocoolers and the traveling-wave thermoacoustic electric generator, a technology that enhances the efficiency of power generation for spacecraft. He contributed to the development of the cryocooler system for the James Webb Space Telescope's Mid-Infrared Instrument (MIRI) and worked on cryocooler concepts for the Origins Space Telescope.