Related Research Articles

Management science is a wide and interdisciplinary study of solving complex problems and making strategic decisions as it pertains to institutions, corporations, governments and other types of organizational entities. It is closely related to management, economics, business, engineering, management consulting, and other fields. It uses various scientific research-based principles, strategies, and analytical methods including mathematical modeling, statistics and numerical algorithms and aims to improve an organization's ability to enact rational and accurate management decisions by arriving at optimal or near optimal solutions to complex decision problems.

In commerce, supply chain management (SCM) deals with a system of procurement, operations management, logistics and marketing channels, through which raw materials can be developed into finished products and delivered to their end customers. A more narrow definition of supply chain management is the "design, planning, execution, control, and monitoring of supply chain activities with the objective of creating net value, building a competitive infrastructure, leveraging worldwide logistics, synchronising supply with demand and measuring performance globally". This can include the movement and storage of raw materials, work-in-process inventory, finished goods, and end to end order fulfilment from the point of origin to the point of consumption. Interconnected, interrelated or interlinked networks, channels and node businesses combine in the provision of products and services required by end customers in a supply chain.

Operations research, often shortened to the initialism OR, is a discipline that deals with the development and application of analytical methods to improve decision-making. The term management science is occasionally used as a synonym.

Logistics engineering is a field of engineering dedicated to the scientific organization of the purchase, transport, storage, distribution, and warehousing of materials and finished goods. Logistics engineering is a complex science that considers trade-offs in component/system design, repair capability, training, spares inventory, demand history, storage and distribution points, transportation methods, etc., to ensure the "thing" is where it's needed, when it's needed, and operating the way it's needed all at an acceptable cost.

A supply chain, sometimes expressed as a "supply-chain", is a complex logistics system that consists of facilities that convert raw materials into finished products and distribute them to end consumers or end customers. Meanwhile, supply chain management deals with the flow of goods within the supply chain in the most efficient manner.

Vendor-managed inventory (VMI) is an inventory management practice in which a supplier of goods, usually the manufacturer, is responsible for optimizing the inventory held by a distributor.

Process engineering is the understanding and application of the fundamental principles and laws of nature that allow humans to transform raw material and energy into products that are useful to society, at an industrial level. By taking advantage of the driving forces of nature such as pressure, temperature and concentration gradients, as well as the law of conservation of mass, process engineers can develop methods to synthesize and purify large quantities of desired chemical products. Process engineering focuses on the design, operation, control, optimization and intensification of chemical, physical, and biological processes. Process engineering encompasses a vast range of industries, such as agriculture, automotive, biotechnical, chemical, food, material development, mining, nuclear, petrochemical, pharmaceutical, and software development. The application of systematic computer-based methods to process engineering is "process systems engineering".

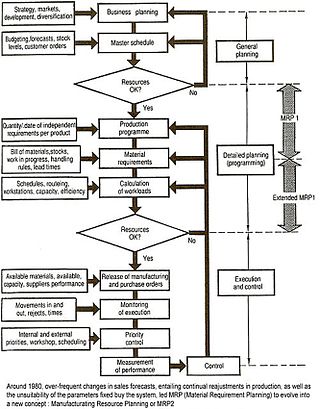

Manufacturingresource planning is a method for the effective planning of all resources of a manufacturing company. Ideally, it addresses operational planning in units, financial planning, and has a simulation capability to answer "what-if" questions and is an extension of closed-loop MRP.

Operations management is concerned with designing and controlling the production of goods and services, ensuring that businesses are efficient in using resources to meet customer requirements.

Inventory control or stock control can be broadly defined as "the activity of checking a shop's stock". It is the process of ensuring that the right amount of supply is available within a business. However, a more focused definition takes into account the more science-based, methodical practice of not only verifying a business's inventory but also maximising the amount of profit from the least amount of inventory investment without affecting customer satisfaction. Other facets of inventory control include forecasting future demand, supply chain management, production control, financial flexibility, purchasing data, loss prevention and turnover, and customer satisfaction.

Financial modeling is the task of building an abstract representation of a real world financial situation. This is a mathematical model designed to represent the performance of a financial asset or portfolio of a business, project, or any other investment.

The term demand chain has been used in a business and management context as contrasting terminology alongside, or in place of, "supply chain". Madhani suggests that the demand chain "comprises all the demand processes necessary to understand, create, and stimulate customer demand". Cranfield School of Management academic Martin Christopher has suggested that "ideally the supply chain should become a demand chain", explaining that ideally all product logistics and processing should occur "in response to a known customer requirement".

Supply-chain optimization (SCO) aims to ensure the optimal operation of a manufacturing and distribution supply chain. This includes the optimal placement of inventory within the supply chain, minimizing operating costs including manufacturing costs, transportation costs, and distribution costs. Optimization often involves the application of mathematical modelling techniques using computer software. It is often considered to be part of supply chain engineering, although the latter is mainly focused on mathematical modelling approaches, whereas supply chain optimization can also be undertaken using qualitative, management based approaches.

Revenue management is a discipline to maximize profit by optimizing rate (ADR) and occupancy (Occ). In its day to day application the maximization of RevPAR is paramount.

Integrated business planning (IBP) is a process for translating desired business outcomes into financial and operational resource requirements, with the overarching objective of maximizing profit and / or cash flow, while cutting down risk. The business outcomes, on which IBP processes focus, can be expressed in terms of the achievement of the following types of targets:

Pricing science is the application of social and business science methods to the problem of setting prices. Methods include economic modeling, statistics, econometrics, mathematical programming. This discipline had its origins in the development of yield management in the airline industry in the 1980s, and has since spread to many other sectors and pricing contexts, including yield management in other travel industry sectors, media, retail, manufacturing and distribution.

Material theory is the sub-specialty within operations research and operations management that is concerned with the design of production/inventory systems to minimize costs: it studies the decisions faced by firms and the military in connection with manufacturing, warehousing, supply chains, spare part allocation and so on and provides the mathematical foundation for logistics. The inventory control problem is the problem faced by a firm that must decide how much to order in each time period to meet demand for its products. The problem can be modeled using mathematical techniques of optimal control, dynamic programming and network optimization. The study of such models is part of inventory theory.

Industrial engineering is an engineering profession that is concerned with the optimization of complex processes, systems, or organizations by developing, improving and implementing integrated systems of people, money, knowledge, information and equipment. Industrial engineering is central to manufacturing operations.

Petrolsoft Corporation (1989–2000) was a supply chain management software company with a focus on the petroleum industry. Petrolsoft Corporation was founded at Stanford University in 1989 by Bill Miller and David Gamboa as Petrolsoft Software Group. It was later incorporated in 1992. Petrolsoft introduced demand-driven inventory management to the petroleum industry.

Industrial and production engineering (IPE) is an interdisciplinary engineering discipline that includes manufacturing technology, engineering sciences, management science, and optimization of complex processes, systems, or organizations. It is concerned with the understanding and application of engineering procedures in manufacturing processes and production methods. Industrial engineering dates back all the way to the industrial revolution, initiated in 1700s by Sir Adam Smith, Henry Ford, Eli Whitney, Frank Gilbreth and Lilian Gilbreth, Henry Gantt, F.W. Taylor, etc. After the 1970s, industrial and production engineering developed worldwide and started to widely use automation and robotics. Industrial and production engineering includes three areas: Mechanical engineering, industrial engineering, and management science.

References

- 1 2 3 4 5 Ravindran, Ravi; Warsing, Donald Jr. (2017). Supply chain engineering : models and applications. CRC Press. ISBN 9781138077720.

- 1 2 3 4 Goetschalckx, Marc (11 August 2011). Supply chain engineering. Springer. ISBN 978-1-4419-6512-7.

- 1 2 Dolgui, Alexander; Proth, Jean-Marie (2 June 2010). Supply chain engineering : useful methods and techniques. Springer. ISBN 978-1-84996-017-5.