Geotechnical engineering, also known as geotechnics, is the branch of civil engineering concerned with the engineering behavior of earth materials. It uses the principles of soil mechanics and rock mechanics to solve its engineering problems. It also relies on knowledge of geology, hydrology, geophysics, and other related sciences.

The cone penetration or cone penetrometer test (CPT) is a method used to determine the geotechnical engineering properties of soils and delineating soil stratigraphy. It was initially developed in the 1950s at the Dutch Laboratory for Soil Mechanics in Delft to investigate soft soils. Based on this history it has also been called the "Dutch cone test". Today, the CPT is one of the most used and accepted soil methods for soil investigation worldwide.

The angle of repose, or critical angle of repose, of a granular material is the steepest angle of descent or dip relative to the horizontal plane on which the material can be piled without slumping. At this angle, the material on the slope face is on the verge of sliding. The angle of repose can range from 0° to 90°. The morphology of the material affects the angle of repose; smooth, rounded sand grains cannot be piled as steeply as can rough, interlocking sands. The angle of repose can also be affected by additions of solvents. If a small amount of water is able to bridge the gaps between particles, electrostatic attraction of the water to mineral surfaces increases the angle of repose, and related quantities such as the soil strength.

Soil liquefaction occurs when a cohesionless saturated or partially saturated soil substantially loses strength and stiffness in response to an applied stress such as shaking during an earthquake or other sudden change in stress condition, in which material that is ordinarily a solid behaves like a liquid. In soil mechanics, the term "liquefied" was first used by Allen Hazen in reference to the 1918 failure of the Calaveras Dam in California. He described the mechanism of flow liquefaction of the embankment dam as:

If the pressure of the water in the pores is great enough to carry all the load, it will have the effect of holding the particles apart and of producing a condition that is practically equivalent to that of quicksand... the initial movement of some part of the material might result in accumulating pressure, first on one point, and then on another, successively, as the early points of concentration were liquefied.

A beam is a structural element that primarily resists loads applied laterally across the beam's axis. Its mode of deflection is primarily by bending, as loads produce reaction forces at the beam's support points and internal bending moments, shear, stresses, strains, and deflections. Beams are characterized by their manner of support, profile, equilibrium conditions, length, and material.

Earthworks are engineering works created through the processing of parts of the earth's surface involving quantities of soil or unformed rock.

Structural health monitoring (SHM) involves the observation and analysis of a system over time using periodically sampled response measurements to monitor changes to the material and geometric properties of engineering structures such as bridges and buildings.

In geotechnical engineering, soil compaction is the process in which stress applied to a soil causes densification as air is displaced from the pores between the soil grains. When stress is applied that causes densification due to water being displaced from between the soil grains, then consolidation, not compaction, has occurred. Normally, compaction is the result of heavy machinery compressing the soil, but it can also occur due to the passage of, for example, animal feet.

Geotechnical investigations are performed by geotechnical engineers or engineering geologists to obtain information on the physical properties of soil earthworks and foundations for proposed structures and for repair of distress to earthworks and structures caused by subsurface conditions; this type of investigation is called a site investigation. Geotechnical investigations are also used to measure the thermal resistance of soils or backfill materials required for underground transmission lines, oil and gas pipelines, radioactive waste disposal, and solar thermal storage facilities. A geotechnical investigation will include surface exploration and subsurface exploration of a site. Sometimes, geophysical methods are used to obtain data about sites. Subsurface exploration usually involves soil sampling and laboratory tests of the soil samples retrieved.

A triaxial shear test is a common method to measure the mechanical properties of many deformable solids, especially soil and rock, and other granular materials or powders. There are several variations on the test.

A deep foundation is a type of foundation that transfers building loads to the earth farther down from the surface than a shallow foundation does to a subsurface layer or a range of depths. A pile or piling is a vertical structural element of a deep foundation, driven or drilled deep into the ground at the building site.

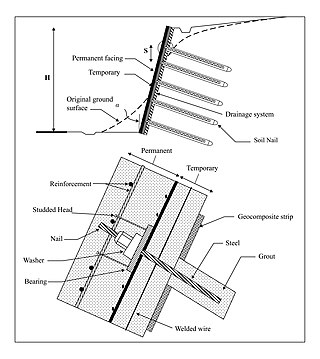

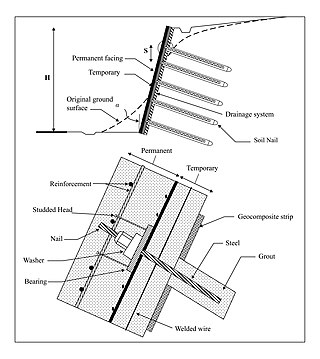

Soil nailing is a remedial construction measure to treat unstable natural soil slopes or unstable man-made (fill) slopes as a construction technique that allows the safe over-steepening of new or existing soil slopes. The technique involves the insertion of relatively slender reinforcing elements into the slope – often general purpose reinforcing bars (rebar) although proprietary solid or hollow-system bars are also available. Solid bars are usually installed into pre-drilled holes and then grouted into place using a separate grout line, whereas hollow bars may be drilled and grouted simultaneously by the use of a sacrificial drill bit and by pumping grout down the hollow bar as drilling progresses. Kinetic methods of firing relatively short bars into soil slopes have also been developed.

Dynamic load testing is a method to assess a pile's bearing capacity by applying a dynamic load to the pile head while recording acceleration and strain on the pile head. Dynamic load testing is a high strain dynamic test which can be applied after pile installation for concrete piles. For steel or timber piles, dynamic load testing can be done during installation or after installation.

National Center for Research on Earthquake Engineering is an organisation in Da'an District, Taipei, Taiwan.

Cellular confinement systems (CCS)—also known as geocells—are widely used in construction for erosion control, soil stabilization on flat ground and steep slopes, channel protection, and structural reinforcement for load support and earth retention. Typical cellular confinement systems are geosynthetics made with ultrasonically welded high-density polyethylene (HDPE) strips or novel polymeric alloy (NPA)—and expanded on-site to form a honeycomb-like structure—and filled with sand, soil, rock, gravel or concrete.

The Statnamic load test is a type of test for assessing the load-carrying capacity of deep foundations which is faster and less expensive than the static load test. The Statnamic test was conceived in 1985, with the first prototype tests carried out in 1988 through collaboration between Berminghammer Foundation Equipment of Canada and TNO Building Research of the Netherlands. Guidance on rapid load pile testing can be found in: Methods for Axial Compressive Force Pulse (Rapid) Testing of Deep Foundations. Sanken D7383 - 08 Standard Test.

The Bridge Software Institute is headquartered at the University of Florida (UF) in Gainesville, Florida. It was established in January 2000 to oversee the development of bridge related software products at UF. Today, Bridge Software Institute products are used by engineers nationwide, both in state Departments of Transportation and leading private consulting firms. Bridge Software Institute software is also used for the analysis of bridges in various countries by engineers around the world.

Solid waste landfills can be affected by seismic activity. The tension in a landfill liner rises significantly during an earthquake, and can lead to stretching or tearing of the material. The top of the landfill may crack, and methane collection systems can be moved relative to the cover.

This information sets out some of the basic considerations taken into account by the lifting design engineer.

Offshore geotechnical engineering is a sub-field of geotechnical engineering. It is concerned with foundation design, construction, maintenance and decommissioning for human-made structures in the sea. Oil platforms, artificial islands and submarine pipelines are examples of such structures. The seabed has to be able to withstand the weight of these structures and the applied loads. Geohazards must also be taken into account. The need for offshore developments stems from a gradual depletion of hydrocarbon reserves onshore or near the coastlines, as new fields are being developed at greater distances offshore and in deeper water, with a corresponding adaptation of the offshore site investigations. Today, there are more than 7,000 offshore platforms operating at a water depth up to and exceeding 2000 m. A typical field development extends over tens of square kilometers, and may comprise several fixed structures, infield flowlines with an export pipeline either to the shoreline or connected to a regional trunkline.