Adobe is a building material made from earth and organic materials. Adobe is Spanish for mudbrick. In some English-speaking regions of Spanish heritage, such as the Southwestern United States, the term is used to refer to any kind of earthen construction, or various architectural styles like Pueblo Revival or Territorial Revival. Most adobe buildings are similar in appearance to cob and rammed earth buildings. Adobe is among the earliest building materials, and is used throughout the world.

Geotechnical engineering, also known as geotechnics, is the branch of civil engineering concerned with the engineering behavior of earth materials. It uses the principles of soil mechanics and rock mechanics for the solution of its respective engineering problems. It also relies on knowledge of geology, hydrology, geophysics, and other related sciences. Geotechnical (rock) engineering is a subdiscipline of civil engineering.

Retaining walls are relatively rigid walls used for supporting soil laterally so that it can be retained at different levels on the two sides. Retaining walls are structures designed to restrain soil to a slope that it would not naturally keep to. They are used to bound soils between two different elevations often in areas of terrain possessing undesirable slopes or in areas where the landscape needs to be shaped severely and engineered for more specific purposes like hillside farming or roadway overpasses. A retaining wall that retains soil on the backside and water on the frontside is called a seawall or a bulkhead.

Earthbag construction is an inexpensive building method using mostly local soil to create structures which are both strong and can be quickly built.

Seismic retrofitting is the modification of existing structures to make them more resistant to seismic activity, ground motion, or soil failure due to earthquakes. With better understanding of seismic demand on structures and with our recent experiences with large earthquakes near urban centers, the need of seismic retrofitting is well acknowledged. Prior to the introduction of modern seismic codes in the late 1960s for developed countries and late 1970s for many other parts of the world, many structures were designed without adequate detailing and reinforcement for seismic protection. In view of the imminent problem, various research work has been carried out. State-of-the-art technical guidelines for seismic assessment, retrofit and rehabilitation have been published around the world – such as the ASCE-SEI 41 and the New Zealand Society for Earthquake Engineering (NZSEE)'s guidelines. These codes must be regularly updated; the 1994 Northridge earthquake brought to light the brittleness of welded steel frames, for example.

Geosynthetics are synthetic products used to stabilize terrain. They are generally polymeric products used to solve civil engineering problems. This includes eight main product categories: geotextiles, geogrids, geonets, geomembranes, geosynthetic clay liners, geofoam, geocells and geocomposites. The polymeric nature of the products makes them suitable for use in the ground where high levels of durability are required. They can also be used in exposed applications. Geosynthetics are available in a wide range of forms and materials. These products have a wide range of applications and are currently used in many civil, geotechnical, transportation, geoenvironmental, hydraulic, and private development applications including roads, airfields, railroads, embankments, retaining structures, reservoirs, canals, dams, erosion control, sediment control, landfill liners, landfill covers, mining, aquaculture and agriculture.

An abutment is the substructure at the ends of a bridge span or dam supporting its superstructure. Single-span bridges have abutments at each end which provide vertical and lateral support for the span, as well as acting as retaining walls to resist lateral movement of the earthen fill of the bridge approach. Multi-span bridges require piers to support ends of spans unsupported by abutments. Dam abutments are generally the sides of a valley or gorge, but may be artificial in order to support arch dams such as Kurobe Dam in Japan.

Geotextiles are permeable fabrics which, when used in association with soil, have the ability to separate, filter, reinforce, protect, or drain. Typically made from polypropylene or polyester, geotextile fabrics come in two basic forms: woven and nonwoven.

Landscape products refers to a group of building industry products used by garden designers and landscape architects and exhibited at trade fairs devoted to these industries. It includes: walls, fences, paving, gardening tools, outdoor lighting, water features, fountains, garden furniture, garden ornaments, gazebos, garden buildings, pond liners.

Geocomposite is a composition / combination of two or more geosynthetic materials to perform multiple number of geosynthetic functions for specific civil engineering application(s) the purpose of providing this composition is to minimize the application costs whereas the technical properties of the soil or the geotechnical structure are enhanced.

An earth structure is a building or other structure made largely from soil. Since soil is a widely available material, it has been used in construction since prehistoric times. It may be combined with other materials, compressed and/or baked to add strength.

A geogrid is geosynthetic material used to reinforce soils and similar materials. Soils pull apart under tension. Compared to soil, geogrids are strong in tension. This fact allows them to transfer forces to a larger area of soil than would otherwise be the case.

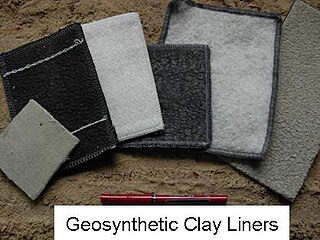

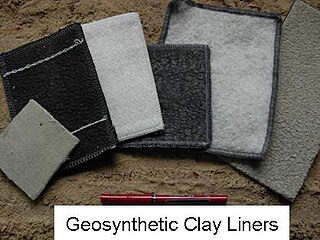

Geosynthetic clay liners (GCLs) are factory manufactured hydraulic barriers consisting of a layer of bentonite or other very low-permeability material supported by geotextiles and/or geomembranes, mechanically held together by needling, stitching, or chemical adhesives. Due to environmental laws, any seepage from landfills must be collected and properly disposed of, otherwise contamination of the surrounding ground water could cause major environmental and/or ecological problems. The lower the hydraulic conductivity the more effective the GCL will be at retaining seepage inside of the landfill. Bentonite composed predominantly (>70%) of montmorillonite or other expansive clays, are preferred and most commonly used in GCLs. A general GCL construction would consist of two layers of geosynthetics stitched together enclosing a layer of natural or processed sodium bentonite. Typically, woven and/or non-woven textile geosynthetics are used, however polyethylene or geomembrane layers or geogrid geotextiles materials have also been incorporated into the design or in place of a textile layer to increase strength. GCLs are produced by several large companies in North America, Europe, and Asia. The United States Environmental Protection Agency currently regulates landfill construction and design in the US through several legislations.

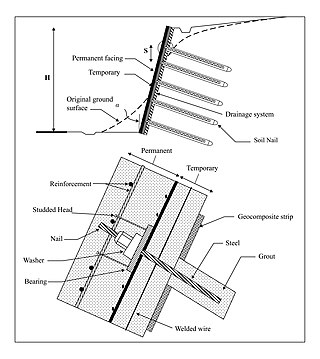

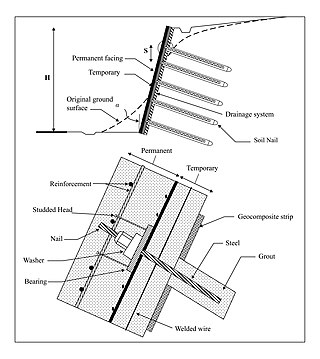

Soil nailing is a remedial construction measure to treat unstable natural soil slopes or unstable man-made (fill) slopes as a construction technique that allows the safe over-steepening of new or existing soil slopes. The technique involves the insertion of relatively slender reinforcing elements into the slope – often general purpose reinforcing bars (rebar) although proprietary solid or hollow-system bars are also available. Solid bars are usually installed into pre-drilled holes and then grouted into place using a separate grout line, whereas hollow bars may be drilled and grouted simultaneously by the use of a sacrificial drill bit and by pumping grout down the hollow bar as drilling progresses. Kinetic methods of firing relatively short bars into soil slopes have also been developed.

Landslide mitigation refers to several man-made activities on slopes with the goal of lessening the effect of landslides. Landslides can be triggered by many, sometimes concomitant causes. In addition to shallow erosion or reduction of shear strength caused by seasonal rainfall, landslides may be triggered by anthropic activities, such as adding excessive weight above the slope, digging at mid-slope or at the foot of the slope. Often, individual phenomena join together to generate instability over time, which often does not allow a reconstruction of the evolution of a particular landslide. Therefore, landslide hazard mitigation measures are not generally classified according to the phenomenon that might cause a landslide. Instead, they are classified by the sort of slope stabilization method used:

Cellular confinement systems (CCS)—also known as geocells—are widely used in construction for erosion control, soil stabilization on flat ground and steep slopes, channel protection, and structural reinforcement for load support and earth retention. Typical cellular confinement systems are geosynthetics made with ultrasonically welded high-density polyethylene (HDPE) strips or novel polymeric alloy (NPA)—and expanded on-site to form a honeycomb-like structure—and filled with sand, soil, rock, gravel or concrete.

A geonet is a geosynthetic material similar in structure to a geogrid, consisting of integrally connected parallel sets of ribs overlying similar sets at various angles for in-plane drainage of liquids or gases. Geonets are often laminated with geotextiles on one or both surfaces and are then referred to as drainage geocomposites. They are competitive with other drainage geocomposites having different core configurations.

Novel polymeric alloy (NPA) is a polymeric alloy composed of polyolefin and thermoplastic engineering polymer with enhanced engineering properties. NPA was developed for use in geosynthetics. One of the first commercial NPA applications was in the manufacturer of polymeric strips used to form Neoloy® cellular confinement systems (geocells).

Jean-Pierre Giroud is a French geotechnical engineer and a pioneer of geosynthetics since 1970. In 1977, he coined the words "geotextile" and "geomembrane", thus initiating the "geo-terminology". He is also a past president of the International Geosynthetics Society, member of the US National Academies, and Chevalier de la Légion d'Honneur.

The Neoloy Geocell is a Cellular Confinement System (geocell) developed and manufactured by PRS Geo-Technologies Ltd. Geocells are extruded in ultrasonically welded strips. The folded strips are opened on-site to form a 3D honeycomb matrix, which is then filled with granular material. The 3D confinement system is used to stabilize soft subgrade soil and reinforce the subbase and base layers in flexible pavements. Cellular confinement is also used for soil protection and erosion control for slopes, including channels, retention walls, reservoirs and landfills.