A loom is a device used to weave cloth and tapestry. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. The precise shape of the loom and its mechanics may vary, but the basic function is the same.

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal threads are called the warp and the lateral threads are the weft, woof, or filling. The method in which these threads are interwoven affects the characteristics of the cloth. Cloth is usually woven on a loom, a device that holds the warp threads in place while filling threads are woven through them. A fabric band that meets this definition of cloth can also be made using other methods, including tablet weaving, back strap loom, or other techniques that can be done without looms.

Ikat is a dyeing technique originating from Indonesia used to pattern textiles that employs resist dyeing on the yarns prior to dyeing and weaving the fabric.

Warp and weft are the two basic components used in weaving to turn thread or yarn into fabric. The lengthwise or longitudinal warp yarns are held stationary in tension on a frame or loom while the transverse weft is drawn through and inserted over and under the warp. A single thread of the weft crossing the warp is called a pick. Terms vary. Each individual warp thread in a fabric is called a warp end or end.

Damask is a reversible patterned fabric of silk, wool, linen, cotton, or synthetic fibers, with a pattern formed by weaving. Damasks are woven with one warp yarn and one weft yarn, usually with the pattern in warp-faced satin weave and the ground in weft-faced or sateen weave. Twill damasks include a twill-woven ground or pattern.

Jamdani is a fine muslin textile produced for centuries in South Rupshi of Narayanganj district on the bank of Shitalakhwa river in what was Bengal and eventually became Bangladesh - see Partition of India.

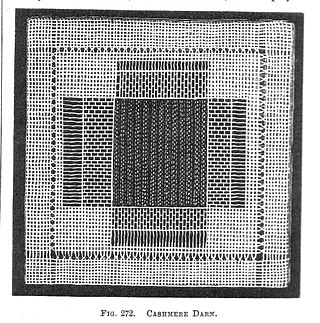

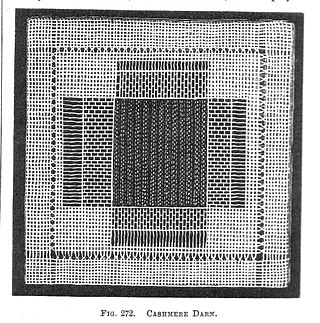

Darning is a sewing technique for repairing holes or worn areas in fabric or knitting using needle and thread alone. It is often done by hand, but it is also possible to darn with a sewing machine. Hand darning employs the darning stitch, a simple running stitch in which the thread is "woven" in rows along the grain of the fabric, with the stitcher reversing direction at the end of each row, and then filling in the framework thus created, as if weaving. Darning is a traditional method for repairing fabric damage or holes that do not run along a seam, and where patching is impractical or would create discomfort for the wearer, such as on the heel of a sock.

Textile Manufacturing or Textile Engineering is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods such as clothing, household items, upholstery and various industrial products.

Paithani is a variety of sari, named after the Paithan town in Aurangabad district from state of Maharashtra in India where the sari was first made by hand. Present day Yeola town in Nashik, Maharashtra is the largest manufacturer of Paithani.

A selvage or selvedge is a "self-finished" edge of a piece of fabric which keeps it from unraveling and fraying. The term "self-finished" means that the edge does not require additional finishing work, such as hem or bias tape, to prevent fraying.

Silk In India, about 97% of the raw mulberry silk is produced in the Indian states of Karnataka, Andhra Pradesh, Tamil Nadu and West Bengal. Mysore and North Bangalore, the upcoming site of a US$20 million "Silk City", contribute to a majority of silk production. Another emerging silk producer is Tamil Nadu where mulberry cultivation is concentrated in Salem, Erode and Dharmapuri districts. Hyderabad, Andhra Pradesh and Gobichettipalayam, Tamil Nadu were the first locations to have automated silk reeling units.

The manufacture of textiles is one of the oldest of human technologies. To make textiles, the first requirement is a source of fiber from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving, which turns yarn into cloth. The machine used for weaving is the loom. For decoration, the process of colouring yarn or the finished material is dyeing. For more information of the various steps, see textile manufacturing.

Textile manufacturing is one of the oldest human activities. The oldest known textiles date back to about 5000 B.C. In order to make textiles, the first requirement is a source of fibre from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving to create cloth. The machine used for weaving is the loom. Cloth is finished by what are described as wet process to become fabric. The fabric may be dyed, printed or decorated by embroidering with coloured yarns.

A Sambalpuri sari is a traditional handwoven bandha (ikat) sari wherein the warp and the weft are tie-dyed before weaving. It is produced in the Sambalpur, Balangir, Bargarh, Boudh and Sonepur districts of Odisha, India. The sari is a traditional female garment in the Indian subcontinent consisting of a strip of unstitched cloth ranging from four to nine metres in length that is draped over the body in various styles.

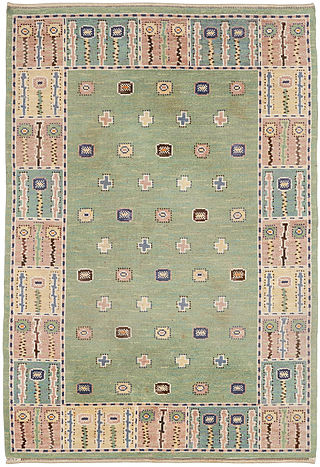

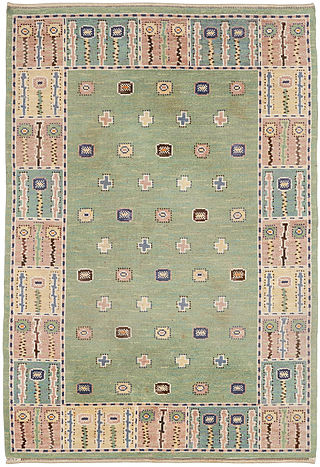

Carpets and rugs have been handmade in Sweden for centuries, taking on many different forms and functions over the course of time. Rugs woven in the traditional Oriental manner, especially in the Ottoman Empire and points east, were originally brought to Sweden over trade routes as early as the early Middle Ages. In the centuries that followed, Swedish rug-makers often infused their works with themes and motifs traditionally found in Oriental rugs. Eventually, Swedish rug-makers would begin to use Oriental rug-making techniques, but themes and motifs more consistent with the artistic and cultural heritage of Sweden. By the early modern periods, rugs had long been an important avenue of art – especially folk art – in Swedish culture. By the beginning of the twentieth century, the craft was seen as being an important artistic and cultural practice throughout Sweden, and designers began to make rugs that had a broad international appeal. Swedish rugs from the mid-twentieth century remain among the most desirable and sought after in the rug world.

Handloom saris are a traditional textile art of Bangladesh and India. The production of handloom saris are important for economic development in rural India.

Odisha Ikat, is a kind of ikat known as Bandhakala and Bandha, a resist dyeing technique, originating from Indian state of Odisha. Traditionally known as "Bandhakala"', "Bandha", '"Bandha of Odisha", it is a geographically tagged product of Odisha since 2007. It is made through a process of tie-dying the warp and weft threads to create the design on the loom prior to weaving. It is unlike any other ikat woven in the rest of the country because of its design process, which has been called "poetry on the loom". This design is in vogue only at the western and eastern regions of Odisha; similar designs are produced by community groups called the Bhulia, Kostha Asani, and Patara. The fabric gives a striking curvilinear appearance. Saris made out of this fabric feature bands of brocade in the borders and also at the ends, called anchal or pallu. Its forms are purposefully feathered, giving the edges a "hazy and fragile" appearance. There are different kinds of bandha saris made in Odisha, notably Khandua, Sambalpuri, Pasapali, Kataki and Manibandhi.

Kotpad Handloom is a vegetable-dyed fabric woven by the tribal weavers of the Mirgan community of Kotpad village in Koraput district, Odisha, India. Cotton sarees with solid border and Pata Anchal, duppatta with typical Buties / motifs, Scolrfs on cotton, silk, handloom stoles, and dress materials are all dyed with organic dyes. The natural dye is manufactured from the aul tree grown in this area. The Kotpad tussar silk saree with tribal art and Kotpad handloom fabrics with natural color is its specialty.

The Khalili Collection of Swedish Textiles is a private collection of textile art assembled by the British-Iranian scholar, collector and philanthropist Nasser D. Khalili. The collection was built up over a period of 25 years and contains 100 works. It is one of eight collections assembled, conserved, published and exhibited by Khalili, each of which is considered among the most important in its field. In 2008 it was described as "the only extensive collection of Swedish flatweaves outside the country". The collection consists mostly of textile panels, cushion and bed covers from the Scania region of southern Sweden, dating in the main from a hundred-year period between the mid-18th and mid-19th centuries. The majority of the pieces in the collection were made for wedding ceremonies in the region. While they played a part in the ceremonies, they were also a reflection of the artistry and skill of the weaver. Their designs often consist of symbolic illustrations of fertility and long life. Khalili writes that he created the collection because of the tendency of art historians and the public to undervalue art whose creators are anonymous.

The swivel weave is a weaving technique that incorporates a decorative element into the fabric by using small shuttles that insert additional weft thread around selected warp threads, while the main weft thread forms the fabric's structure. This method differs from the plain weave, which lacks this decorative aspect.