Related Research Articles

Cellulose is an organic compound with the formula (C

6H

10O

5)

n, a polysaccharide consisting of a linear chain of several hundred to many thousands of β(1→4) linked D-glucose units. Cellulose is an important structural component of the primary cell wall of green plants, many forms of algae and the oomycetes. Some species of bacteria secrete it to form biofilms. Cellulose is the most abundant organic polymer on Earth. The cellulose content of cotton fiber is 90%, that of wood is 40–50%, and that of dried hemp is approximately 57%.

Cavitation is a phenomenon in which the static pressure of a liquid reduces to below the liquid's vapour pressure, leading to the formation of small vapor-filled cavities in the liquid. When subjected to higher pressure, these cavities, called "bubbles" or "voids", collapse and can generate shock waves that may damage machinery. These shock waves are strong when they are very close to the imploded bubble, but rapidly weaken as they propagate away from the implosion. Cavitation is a significant cause of wear in some engineering contexts. Collapsing voids that implode near to a metal surface cause cyclic stress through repeated implosion. This results in surface fatigue of the metal, causing a type of wear also called "cavitation". The most common examples of this kind of wear are to pump impellers, and bends where a sudden change in the direction of liquid occurs. Cavitation is usually divided into two classes of behavior: inertial cavitation and non-inertial cavitation.

An emulsion is a mixture of two or more liquids that are normally immiscible owing to liquid-liquid phase separation. Emulsions are part of a more general class of two-phase systems of matter called colloids. Although the terms colloid and emulsion are sometimes used interchangeably, emulsion should be used when both phases, dispersed and continuous, are liquids. In an emulsion, one liquid is dispersed in the other. Examples of emulsions include vinaigrettes, homogenized milk, liquid biomolecular condensates, and some cutting fluids for metal working.

A discrete element method (DEM), also called a distinct element method, is any of a family of numerical methods for computing the motion and effect of a large number of small particles. Though DEM is very closely related to molecular dynamics, the method is generally distinguished by its inclusion of rotational degrees-of-freedom as well as stateful contact and often complicated geometries. With advances in computing power and numerical algorithms for nearest neighbor sorting, it has become possible to numerically simulate millions of particles on a single processor. Today DEM is becoming widely accepted as an effective method of addressing engineering problems in granular and discontinuous materials, especially in granular flows, powder mechanics, and rock mechanics. DEM has been extended into the Extended Discrete Element Method taking heat transfer, chemical reaction and coupling to CFD and FEM into account.

Xanthan gum is a polysaccharide with many industrial uses, including as a common food additive. It is an effective thickening agent, emulsifier, and stabilizer that prevents ingredients from separating. It can be produced from simple sugars using a fermentation process and derives its name from the species of bacteria used, Xanthomonas campestris.

Soft matter or soft condensed matter is a subfield of condensed matter comprising a variety of physical systems that are deformed or structurally altered by thermal or mechanical stress of the magnitude of thermal fluctuations. These materials share an important common feature in that predominant physical behaviors occur at an energy scale comparable with room temperature thermal energy, and that entropy is considered the dominant factor. At these temperatures, quantum aspects are generally unimportant. Soft materials include liquids, colloids, polymers, foams, gels, granular materials, liquid crystals, flesh, and a number of biomaterials. When soft materials interact favorably with surfaces, they become squashed without an external compressive force. Pierre-Gilles de Gennes, who has been called the "founding father of soft matter," received the Nobel Prize in Physics in 1991 for discovering that methods developed for studying order phenomena in simple systems can be generalized to the more complex cases found in soft matter, in particular, to the behaviors of liquid crystals and polymers.

In industrial process engineering, mixing is a unit operation that involves manipulation of a heterogeneous physical system with the intent to make it more homogeneous. Familiar examples include pumping of the water in a swimming pool to homogenize the water temperature, and the stirring of pancake batter to eliminate lumps (deagglomeration).

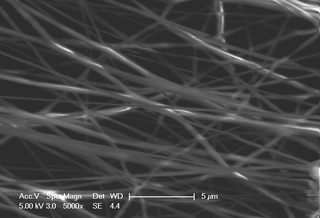

Electrospinning is a fiber production method that uses electric force to draw charged threads of polymer solutions or polymer melts up to fiber diameters in the order of some hundred nanometers. Electrospinning shares characteristics of both electrospraying and conventional solution dry spinning of fibers. The process does not require the use of coagulation chemistry or high temperatures to produce solid threads from solution. This makes the process particularly suited to the production of fibers using large and complex molecules. Electrospinning from molten precursors is also practiced; this method ensures that no solvent can be carried over into the final product.

Sonication is the act of applying sound energy to agitate particles in a sample, for various purposes such as the extraction of multiple compounds from plants, microalgae and seaweeds. Ultrasonic frequencies (> 20 kHz) are usually used, leading to the process also being known as ultrasonication or ultra-sonication.

Deep eutectic solvents or DESs are solutions of Lewis or Brønsted acids and bases which form a eutectic mixture. Deep eutectic solvents are highly tunable through varying the structure or relative ratio of parent components and thus have a wide variety of potential applications including catalytic, separation, and electrochemical processes. The parent components of deep eutectic solvents engage in a complex hydrogen bonding network which results in significant freezing point depression as compared to the parent compounds. The extent of freezing point depression observed in DESs is well illustrated by a mixture of choline chloride and urea in a 1:2 mole ratio. Choline chloride and urea are both solids at room temperature with melting points of 302 °C and 133 °C respectively, yet the combination of the two in a 1:2 molar ratio forms a liquid with a freezing point of 12 °C. DESs share similar properties to ionic liquids such as tunability and lack of flammability yet are distinct in that ionic liquids are neat salts composed exclusively of discrete ions. In contrast to ordinary solvents, such as Volatile Organic Compounds (VOC), DESs are non-flammable, and possess low vapour pressures and toxicity.

The ouzo effect, also known as the louche effect and spontaneous emulsification, is a milky oil-in-water emulsion that is formed when water is added to ouzo and other anise-flavored liqueurs and spirits, such as pastis, rakı, arak, sambuca and absinthe. Such emulsions occur with only minimal mixing and are highly stable.

Chaotic bubbles within physics and mathematics, occur in cases when there are any dynamic processes that generate bubbles that are nonlinear. Many exhibit mathematically chaotic patterns consistent with chaos theory. In most systems, they arise out of a forcing pressure that encounters some kind of resistance or shear factor, but the details vary depending on the particular context.

The CFD-DEM model, or Computational Fluid Dynamics / Discrete Element Method model, is a process used to model or simulate systems combining fluids with solids or particles. In CFD-DEM, the motion of discrete solids or particles phase is obtained by the Discrete Element Method (DEM) which applies Newton's laws of motion to every particle, while the flow of continuum fluid is described by the local averaged Navier–Stokes equations that can be solved using the traditional Computational Fluid Dynamics (CFD) approach. The interactions between the fluid phase and solids phase is modeled by use of Newton's third law.

Environmental Stress Cracking (ESC) is one of the most common causes of unexpected brittle failure of thermoplastic polymers known at present. According to ASTM D883, stress cracking is defined as "an external or internal crack in a plastic caused by tensile stresses less than its short-term mechanical strength". This type of cracking typically involves brittle cracking, with little or no ductile drawing of the material from its adjacent failure surfaces. Environmental stress cracking may account for around 15-30% of all plastic component failures in service. This behavior is especially prevalent in glassy, amorphous thermoplastics. Amorphous polymers exhibit ESC because of their loose structure which makes it easier for the fluid to permeate into the polymer. Amorphous polymers are more prone to ESC at temperature higher than their glass transition temperature (Tg) due to the increased free volume. When Tg is approached, more fluid can permeate into the polymer chains.

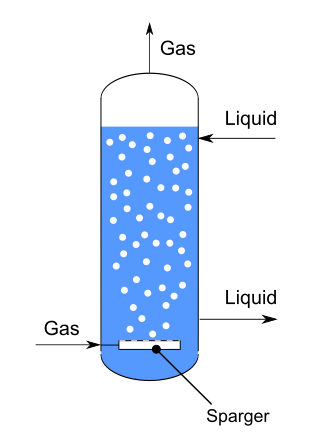

A bubble column reactor is a chemical reactor that belongs to the general class of multiphase reactors, which consists of three main categories: trickle bed reactor, fluidized bed reactor, and bubble column reactor. A bubble column reactor is a very simple device consisting of a vertical vessel filled with water with a gas distributor at the inlet. Due to the ease of design and operation, which does not involve moving parts, they are widely used in the chemical, biochemical, petrochemical, and pharmaceutical industries to generate and control gas-liquid chemical reactions.

Membrane emulsification (ME) is a relatively novel technique for producing all types of single and multiple emulsions for DDS, solid micro carriers for encapsulation of drug or nutrient, solder particles for surface-mount technology, mono dispersed polymer microspheres. Membrane emulsification was introduced by Nakashima and Shimizu in the late 1980s in Japan.

Rakesh Agrawal is a chemical engineer known for contributions to separations, cryogenic gas separation and liquefaction, and for contributions to renewable energy including the conversion of biomass to chemicals and fuels, inorganic solar cell fabrication, and the synergistic use of solar energy. He is the Winthrop E. Stone Distinguished Professor of Chemical Engineering at Purdue University.

Dimitris Drikakis, PhD, FRAeS, CEng, is a Greek-British applied scientist, engineer and university professor. His research is multidisciplinary. It covers fluid dynamics, computational fluid dynamics, acoustics, heat transfer, computational science from molecular to macro scale, materials, machine learning, and emerging technologies. He has applied his research to diverse fields such as Aerospace & Defence, Biomedical, and Energy and Environment Sectors. He received The William Penney Fellowship Award by the Atomic Weapons Establishment to recognise his contributions to compressible fluid dynamics. He was also the winner of NEF's Innovator of the Year Award by the UK's Institute of Innovation and Knowledge Exchange for a new generation carbon capture nanotechnology that uses carbon nanotubes for filtering out carbon dioxide and other gases.

Pillow-plate heat exchangers are a class of fully welded heat exchanger design, which exhibit a wavy, “pillow-shaped” surface formed by an inflation process. Compared to more conventional equipment, such as shell and tube and plate and frame heat exchangers, pillow plates are a quite young technology. Due to their geometric flexibility, they are used as well as “plate-type” heat exchangers and as jackets for cooling or heating of vessels. Pillow plate equipment is currently experiencing increased attention and implementation in process industry.

Deresh RamjugernathFAAS is a South African professor of Engineering Technology & Applied Sciences. He was a Deputy Vice-Chancellor of Research at the University of KwaZulu-Natal (UKZN) and the current Deputy Vice-Chancellor of Learning and Teaching at Stellenbosch University (SU).

References

- ↑ Ryan, David; Simmons, Mark; Baker, Michael (2017). "Determination of the flow field inside a Sonolator liquid whistle using PIV and CFD". Chemical Engineering Science. 163: 123–136. doi: 10.1016/j.ces.2017.01.035 .

- ↑ Ryan, David; Baker, Michael; Kowalski, Adam; Simmons, Mark (2018). "Emulsification using a "Sonolator" liquid whistle: A new correlation for droplet size from pilot-scale experiments" (PDF). Chemical Engineering Science. 189: 369–379. doi: 10.1016/j.ces.2018.06.004 .

- ↑ Ryan, David (2015). Investigation of Fluid Dynamics and Emulsification in Sonolator Liquid Whistles (EngD.). University of Birmingham, UK. Retrieved 1 Sep 2015.