A router is a hand tool or power tool that routs an area in hard material, such as wood or plastic. Routers are mainly used in woodworking, especially cabinetry. Usually they're handheld or fastened, with the cutting end up, in router tables.

A circular saw is a power-saw using a toothed or abrasive disc or blade to cut different materials using a rotary motion spinning around an arbor. A hole saw and ring saw also use a rotary motion but are different from a circular saw. Circular saws may also be loosely used for the blade itself. Circular saws were invented in the late 18th century and were in common use in sawmills in the United States by the middle of the 19th century.

A saw is a tool consisting of a tough blade, wire, or chain with a hard toothed edge. It is used to cut through material, very often wood though sometimes metal or stone. The cut is made by placing the toothed edge against the material and moving it forcefully forth and less forcefully back or continuously forward. This force may be applied by hand, or powered by steam, water, electricity or other power source. An abrasive saw has a powered circular blade designed to cut through metal or ceramic.

Drill bits are cutting tools used to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shapes and can create different kinds of holes in many different materials. In order to create holes drill bits are usually attached to a drill, which powers them to cut through the workpiece, typically by rotation. The drill will grasp the upper end of a bit called the shank in the chuck.

A bandsaw is a power saw with a long, sharp blade consisting of a continuous band of toothed metal stretched between two or more wheels to cut material. They are used principally in woodworking, metalworking, and lumbering, but may cut a variety of materials. Advantages include uniform cutting action as a result of an evenly distributed tooth load, and the ability to cut irregular or curved shapes like a jigsaw. The minimum radius of a curve is determined by the width of the band and its kerf. Most bandsaws have two wheels rotating in the same plane, one of which is powered, although some may have three or four to distribute the load. The blade itself can come in a variety of sizes and tooth pitches, which enables the machine to be highly versatile and able to cut a wide variety of materials including wood, metal and plastic.

A reciprocating saw is a type of machine-powered saw in which the cutting action is achieved through a push-and-pull ("reciprocating") motion of the blade.

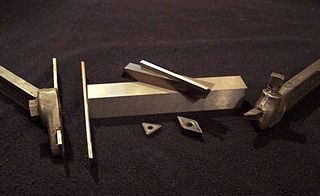

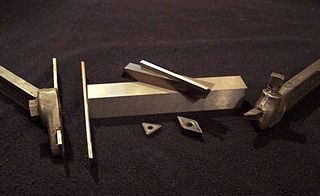

A tool bit is a non-rotary cutting tool used in metal lathes, shapers, and planers. Such cutters are also often referred to by the set-phrase name of single-point cutting tool, as distinguished from other cutting tools such as a saw or water jet cutter. The cutting edge is ground to suit a particular machining operation and may be resharpened or reshaped as needed. The ground tool bit is held rigidly by a tool holder while it is cutting.

Milling cutters are cutting tools typically used in milling machines or machining centres to perform milling operations. They remove material by their movement within the machine or directly from the cutter's shape.

A scroll saw is a small electric or pedal-operated saw used to cut intricate curves in wood, metal, or other materials. The fineness of its blade allows it to cut more delicately than a power jigsaw, and more easily than a hand coping saw or fretsaw. Like those tools, it is capable of creating curves with edges, by pivoting its table.

A tipped tool is any cutting tool in which the cutting edge consists of a separate piece of material that is brazed, welded, or clamped onto a body made of another material. In the types in which the cutter portion is an indexable part clamped by a screw, the cutters are called inserts. Tipped tools allow each part of the tool, the shank and the cutter(s), to be made of the material with the best properties for its job. Common materials for the cutters include cemented carbide, polycrystalline diamond, and cubic boron nitride. Tools that are commonly tipped include milling cutters, tool bits, router bits, and saw blades.

Sharpening stones, water stones or whetstones are used to sharpen the edges of steel tools and implements through grinding and honing.

A diamond tool is a cutting tool with diamond grains fixed on the functional parts of the tool via a bonding material or another method. As diamond is a superhard material, diamond tools have many advantages as compared with tools made with common abrasives such as corundum and silicon carbide.

A diamond blade is a saw blade which has diamonds fixed on its edge for cutting hard or abrasive materials. There are many types of diamond blade, and they have many uses, including cutting stone, concrete, asphalt, bricks, coal balls, glass, and ceramics in the construction industry; cutting semiconductor materials in the IT industry; and cutting gemstones, including diamonds, in the gem industry.

A cold saw is a circular saw designed to cut metal which uses a toothed blade to transfer the heat generated by cutting to the chips created by the saw blade, allowing both the blade and material being cut to remain cool. This is in contrast to an abrasive saw, which abrades the metal and generates a great deal of heat absorbed by the material being cut and saw blade.

Cemented carbide is a hard material used extensively as cutting tool material, as well as other industrial applications. It consists of fine particles of carbide cemented into a composite by a binder metal. Cemented carbides commonly use tungsten carbide (WC), titanium carbide (TiC), or tantalum carbide (TaC) as the aggregate. Mentions of "carbide" or "tungsten carbide" in industrial contexts usually refer to these cemented composites.

Arbor milling is a cutting process which removes material via a multi-toothed cutter. An arbor mill is a type of milling machine characterized by its ability to rapidly remove material from a variety of materials. This milling process is not only rapid but also versatile.

A [power] multi-tool, oscillating tool, or oscillating power tool is a power tool that oscillates, powered by battery or mains. The name "multi-tool" is a reference to the many functions that this tool can perform with the range of attachments available. "Master Tool" is also a trade name used in North America, short for the original tool by Fein called the Multi-Master. Attachments are available for sawing, sanding, rasping, grinding, scraping, cutting, and polishing.

Carbide saws are machine tools for cutting. The saw teeth are made of cemented carbide, so that hard materials can be cut.

A jigsaw is a saw which uses a reciprocating blade to cut irregular curves, such as stenciled designs, in wood, metal, or other materials. Today they are electrically powered and known as scroll saws, and have been largely displaced by portable power jigsaws.

Boat building uses many common house tools such as hammers, crosscut saws, power drills, benches and vises.