A wing is a type of fin that produces both lift and drag while moving through air. Wings are defined by two shape characteristics, an airfoil section and a planform. Wing efficiency is expressed as lift-to-drag ratio, which compares the benefit of lift with the air resistance of a given wing shape, as it flies. Aerodynamics is the study of wing performance in air.

A fixed-wing aircraft is a heavier-than-air aircraft, such as an airplane, which is capable of flight using aerodynamic lift. Fixed-wing aircraft are distinct from rotary-wing aircraft, and ornithopters. The wings of a fixed-wing aircraft are not necessarily rigid; kites, hang gliders, variable-sweep wing aircraft, and airplanes that use wing morphing are all classified as fixed wing.

Aeroelasticity is the branch of physics and engineering studying the interactions between the inertial, elastic, and aerodynamic forces occurring while an elastic body is exposed to a fluid flow. The study of aeroelasticity may be broadly classified into two fields: static aeroelasticity dealing with the static or steady state response of an elastic body to a fluid flow, and dynamic aeroelasticity dealing with the body's dynamic response.

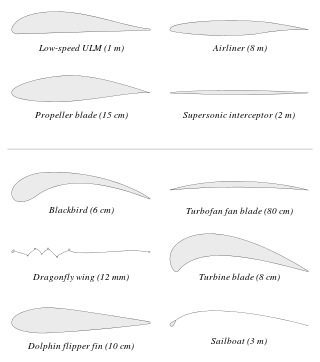

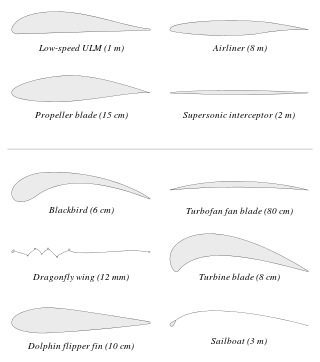

An airfoil or aerofoil is a streamlined body that is capable of generating significantly more lift than drag. Wings, sails and propeller blades are examples of airfoils. Foils of similar function designed with water as the working fluid are called hydrofoils.

Elevons or tailerons are aircraft control surfaces that combine the functions of the elevator and the aileron, hence the name. They are frequently used on tailless aircraft such as flying wings. An elevon that is not part of the main wing, but instead is a separate tail surface, is a stabilator.

A conventional fixed-wing aircraft flight control system (AFCS) consists of flight control surfaces, the respective cockpit controls, connecting linkages, and the necessary operating mechanisms to control an aircraft's direction in flight. Aircraft engine controls are also considered flight controls as they change speed.

Elevators are flight control surfaces, usually at the rear of an aircraft, which control the aircraft's pitch, and therefore the angle of attack and the lift of the wing. The elevators are usually hinged to the tailplane or horizontal stabilizer. They may be the only pitch control surface present, and are sometimes located at the front of the aircraft or integrated into a rear "all-moving tailplane", also called a slab elevator or stabilator.

A flap is a high-lift device used to reduce the stalling speed of an aircraft wing at a given weight. Flaps are usually mounted on the wing trailing edges of a fixed-wing aircraft. Flaps are used to reduce the take-off distance and the landing distance. Flaps also cause an increase in drag so they are retracted when not needed.

A flaperon on an aircraft's wing is a type of control surface that combines the functions of both flaps and ailerons. Some smaller kitplanes have flaperons for reasons of simplicity of manufacture, while some large commercial aircraft such as the Boeing 747, 767, 777, and 787 may have a flaperon between the flaps and aileron. The 787 has a configuration known as a SpoileFlaperon that combines the action of spoilers, flaps and ailerons into one control surface.

Variable camber is a feature of some of aircraft wings that changes the camber of the main aerofoil during flight.

In aeronautics and aeronautical engineering, camber is the asymmetry between the two acting surfaces of an airfoil, with the top surface of a wing commonly being more convex. An airfoil that is not cambered is called a symmetric airfoil. The benefits of cambering were discovered and first utilized by George Cayley in the early 19th century.

The X-53 Active Aeroelastic Wing (AAW) development program is a completed American research project that was undertaken jointly by the Air Force Research Laboratory (AFRL), Boeing Phantom Works and NASA's Dryden Flight Research Center, where the technology was flight tested on a modified McDonnell Douglas F/A-18 Hornet. Active Aeroelastic Wing Technology is a technology that integrates wing aerodynamics, controls, and structure to harness and control wing aeroelastic twist at high speeds and dynamic pressures. By using multiple leading and trailing edge controls like "aerodynamic tabs", subtle amounts of aeroelastic twist can be controlled to provide large amounts of wing control power, while minimizing maneuver air loads at high wing strain conditions or aerodynamic drag at low wing strain conditions. This program was the first full-scale proof of AAW technology.

The Parker variable wing is a wing configuration in biplane or triplane aircraft designed by H.F. Parker in 1920. His design allows a supplement in lift while landing or taking-off. The system is depicted in the figure. The figure shows the biplane configuration. The lower airfoil is rigid. The upper airfoil is flexible. At high angle of attack the flow over the lower airfoil will cause the airflow to bend up and create an upward force at the lower surface of the upper airfoil. This upward force will cause the flexible section to be pushed upward. The flexible wing section is held at points A and B. The trailing edge is rigid and can rotate about point B. Due to this effect the camber of the airfoil is increased, and hence the lift it creates is increased.

A wingsail, twin-skin sail or double skin sail is a variable-camber aerodynamic structure that is fitted to a marine vessel in place of conventional sails. Wingsails are analogous to airplane wings, except that they are designed to provide lift on either side to accommodate being on either tack. Whereas wings adjust camber with flaps, wingsails adjust camber with a flexible or jointed structure. Wingsails are typically mounted on an unstayed spar—often made of carbon fiber for lightness and strength. The geometry of wingsails provides more lift, and a better lift-to-drag ratio, than traditional sails. Wingsails are more complex and expensive than conventional sails.

The wing configuration of a fixed-wing aircraft is its arrangement of lifting and related surfaces.

A slat is an aerodynamic surface on the leading edge of the wing of a fixed-wing aircraft. When retracted, the slat lies flush with the rest of the wing. A slat is deployed by sliding forward, opening a slot between the wing and the slat. Air from below the slat flows through the slot and replaces the boundary layer that has travelled at high speed around the leading edge of the slat, losing a significant amount of its kinetic energy due to skin friction drag. When deployed, slats allow the wings to operate at a higher angle of attack before stalling. With slats deployed an aircraft can fly at slower speeds, allowing it to take off and land in shorter distances. They are used during takeoff and landing and while performing low-speed maneuvers which may take the aircraft close to a stall. Slats are retracted in normal flight to minimize drag.

In aeronautics, a flexible wing is an airfoil or aircraft wing which can deform in flight.

In aeronautics, Distributed propulsion is an arrangement in which the propulsive and related air flows are distributed over the aerodynamic surfaces of an aircraft. The purpose is to improve the craft's aerodynamic, propulsive and/or structural efficiency over an equivalent conventional design.

Adaptive Compliant Trailing Edge (ACTE) is a research project on shape-changing flaps for aircraft wings, intended to reduce the aircraft's fuel costs and reduce noise during take-off and landing. It is a join effort by NASA and the U.S. Air Force Research Laboratory and first airborne tests have been conducted in late 2014.

The General Dynamics–Boeing AFTI/F-111A Aardvark is a research aircraft modified from a General Dynamics F-111 Aardvark to test a Boeing-built supercritical mission adaptive wing (MAW). This MAW, in contrast to standard control surfaces, could smoothly change the shape of its airfoil in flight.