| |||

| |||

| |||

| Names | |||

|---|---|---|---|

| IUPAC name Styrene [1] | |||

| Systematic IUPAC name Ethenylbenzene [2] | |||

| Other names | |||

| Identifiers | |||

3D model (JSmol) | |||

| 1071236 | |||

| ChEBI | |||

| ChEMBL | |||

| ChemSpider | |||

| ECHA InfoCard | 100.002.592 | ||

| EC Number |

| ||

| 2991 | |||

| KEGG | |||

PubChem CID | |||

| RTECS number |

| ||

| UNII | |||

| UN number | 2055 | ||

CompTox Dashboard (EPA) | |||

| |||

| |||

| Properties | |||

| C8H8 | |||

| Molar mass | 104.15 g/mol | ||

| Appearance | colorless oily liquid | ||

| Odor | sweet and floral [3] | ||

| Density | 0.909 g/cm3 | ||

| Melting point | −30 °C (−22 °F; 243 K) | ||

| Boiling point | 145 °C (293 °F; 418 K) | ||

| 0.03% (20 °C) [3] | |||

| log P | 2.70 [4] | ||

| Vapor pressure | 5 mmHg (20 °C) [3] | ||

| −6.82×10−5 cm3/mol | |||

Refractive index (nD) | 1.5469 | ||

| Viscosity | 0.762 cP at 20 °C | ||

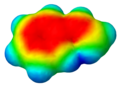

| Structure | |||

| 0.13 D | |||

| Hazards | |||

| Occupational safety and health (OHS/OSH): | |||

Main hazards | flammable, toxic, probably carcinogenic | ||

| GHS labelling: | |||

| |||

| Danger | |||

| H226, H315, H319, H332, H361, H372 | |||

| P201, P202, P210, P233, P240, P241, P242, P243, P260, P261, P264, P270, P271, P280, P281, P302+P352, P303+P361+P353, P304+P312, P304+P340, P305+P351+P338, P308+P313, P312, P314, P321, P332+P313, P337+P313, P362, P370+P378, P403+P235, P405, P501 | |||

| NFPA 704 (fire diamond) | |||

| Flash point | 31 °C (88 °F; 304 K) | ||

| Explosive limits | 0.9–6.8% [3] | ||

| Lethal dose or concentration (LD, LC): | |||

LC50 (median concentration) | 2194 ppm (mouse, 4 h) 5543 ppm (rat, 4 h) [5] | ||

LCLo (lowest published) | 10,000 ppm (human, 30 min) 2771 ppm (rat, 4 h) [5] | ||

| NIOSH (US health exposure limits): | |||

PEL (Permissible) | TWA 100 ppm C 200 ppm 600 ppm (5-minute maximum peak in any 3 hours) [3] | ||

REL (Recommended) | TWA 50 ppm (215 mg/m3) ST 100 ppm (425 mg/m3) [3] | ||

IDLH (Immediate danger) | 700 ppm [3] | ||

| Safety data sheet (SDS) | SDS | ||

| Related compounds | |||

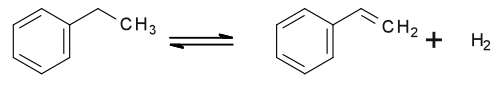

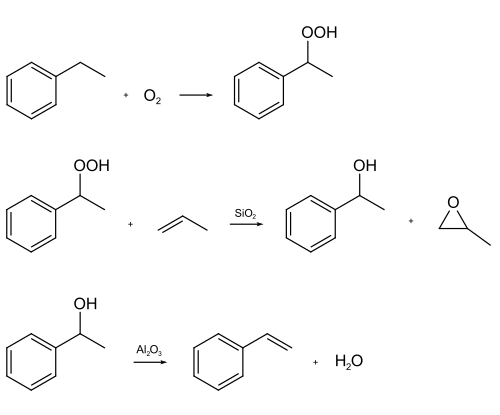

Related styrenes; related aromatic compounds | polystyrene, stilbene; ethylbenzene | ||

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |||

Styrene is an organic compound with the chemical formula C6H5CH=CH2. Its structure consists of a vinyl group as substituent on benzene. Styrene is a colorless, oily liquid, although aged samples can appear yellowish. The compound evaporates easily and has a sweet smell, although high concentrations have a less pleasant odor.[ vague ] Styrene is the precursor to polystyrene and several copolymers, and is typically made from benzene for this purpose. Approximately 25 million tonnes of styrene were produced in 2010, [6] increasing to around 35 million tonnes by 2018.