A dipstick is one of several measurement devices.

A falling weight deflectometer (FWD) is a testing device used by civil engineers to evaluate the physical properties of pavement in highways, local roads, airport pavements, harbor areas, railway tracks and elsewhere. The data acquired from FWDs is primarily used to estimate pavement structural capacity, to facilitate overlay design or determine if a pavement is being overloaded. Depending on its design, a FWD may be contained within a towable trailer or it may be built into a self-propelled vehicle such as a truck or van. Comprehensive road survey vehicles typically consist of a FWD mounted on a heavy truck together with a ground-penetrating radar and impact attenuator.

Weigh-in-motion or weighing-in-motion (WIM) devices are designed to capture and record the axle weights and gross vehicle weights as vehicles drive over a measurement site. Unlike static scales, WIM systems are capable of measuring vehicles traveling at a reduced or normal traffic speed and do not require the vehicle to come to a stop. This makes the weighing process more efficient, and, in the case of commercial vehicles, allows for trucks under the weight limit to bypass static scales or inspection.

The AASHO Road Test was a series of experiments carried out by the American Association of State Highway and Transportation Officials (AASHTO), to determine how traffic contributed to the deterioration of highway pavements.

A rut is a depression or groove worn into a road or path by the travel of wheels or skis. Ruts can be formed by wear, as from studded snow tires common in cold climate areas, or they can form through the deformation of the asphalt concrete, pavement or subbase material. In modern roads the main cause is heavily loaded trucks. These heavy loaded trucks imprint their tire impressions on roads over time, causing ruts. Rut is a common pavement distress and is often used in pavement performance modeling.

The pavement condition index (PCI) is a numerical index between 0 and 100, which is used to indicate the general condition of a pavement section. The PCI is widely used in transportation civil engineering and asset management, and many municipalities use it to measure the performance of their road infrastructure and their levels of service. It is a statistical measure and requires manual survey of the pavement. This index was originally developed by the United States Army Corps of Engineers as an airfield pavement rating system, but later modified for roadway pavements and standardized by the ASTM. The surveying processes and calculation methods have been documented and standardized by ASTM for both roads and airport pavements:

A road is a thoroughfare, route, or way on land between two places that has been surfaced or otherwise improved to allow travel by foot or some form of conveyance, including a motor vehicle, cart, bicycle, or horse. Roads have been adapted to a large range of structures and types in order to achieve a common goal of transportation under a large and wide range of conditions. The specific purpose, mode of transport, material and location of a road determine the characteristics it must have in order to maximize its usefulness. Following is one classification scheme.

Road slipperiness is a condition of low skid resistance due to insufficient road friction. It is a result of snow, ice, water, loose material and the texture of the road surface on the traction produced by the wheels of a vehicle.

Pavement management is the process of planning the maintenance and repair of a network of roadways or other paved facilities in order to optimize pavement conditions over the entire network.

Road surface textures are deviations from a planar and smooth surface, affecting the vehicle/tyre interaction. Pavement texture is divided into: microtexture with wavelengths from 0 mm to 0.5 millimetres (0.020 in), macrotexture with wavelengths from 0.5 millimetres (0.020 in) to 50 millimetres (2.0 in) and megatexture with wavelengths from 50 millimetres (2.0 in) to 500 millimetres (20 in).

An air data boom provides air pressure, temperature, and airflow direction data to data acquisition systems for the computation of air, ground, and water vehicle orientation, speed, altitude/depth, and related information. Air data booms can be used as primary sensors or as a "measurement standard" of which primary sensors and instruments are compared to.

Bleeding or flushing is shiny, black surface film of asphalt on the road surface caused by upward movement of asphalt in the pavement surface. Common causes of bleeding are too much asphalt in asphalt concrete, hot weather, low space air void content and quality of asphalt. Bleeding is a safety concern since it results in a very smooth surface, without the texture required to prevent hydroplaning. Road performance measures such as IRI cannot capture the existence of bleeding as it does not increase the surface roughness. But other performance measures such as PCI do include bleeding.

The Transportation Research Center (TRC) is North America's largest multi-user automotive proving ground. It is operated by TRC Inc. The center occupies 4,500 acres in East Liberty, Ohio, about 40 miles northwest of Columbus, Ohio. These 4,500 acres are split between the main TRC property and a rural road/ATV course located approximately 2.5 miles from the main property.

Pavement performance modeling or pavement deterioration modeling is the study of pavement deterioration throughout its life-cycle. The health of pavement is assessed using different performance indicators. Some of the most well-known performance indicators are Pavement Condition Index (PCI), International Roughness Index (IRI) and Present Serviceability Index (PSI), but sometimes a single distress such as rutting or the extent of crack is used. Among the most frequently used methods for pavement performance modeling are mechanistic models, mechanistic-empirical models, survival curves and Markov models. Recently, machine learning algorithms have been used for this purpose as well. Most studies on pavement performance modeling are based on IRI.

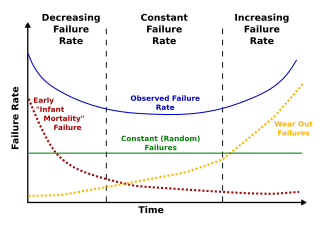

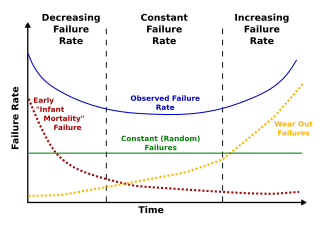

Deterioration modeling is the process of modeling and predicting the physical conditions of equipment, structures, infrastructure or any other physical assets. The condition of infrastructure is represented either using a deterministic index or the probability of failure. Examples of such performance measures are pavement condition index for roads or bridge condition index for bridges. For probabilistic measures, which are the focus of reliability theory, probability of failure or reliability index are used. Deterioration models are instrumental to infrastructure asset management and are the basis for maintenance and rehabilitation decision-making. The condition of all physical infrastructure degrade over time. A deterioration model can help decision-makers to understand how fast the condition drops or violates a certain threshold.

Levels of service (LOS) is a term in asset management referring to the quality of a given service. Defining and measuring levels of service is a key activity in developing infrastructure asset management plans. Levels of service may be tied to physical performance of assets or be defined via customer expectation and satisfaction. The latter is more service-centric rather than asset-centric. For instance, when measuring the LOS of a road, it could be measured by a physical performance indicator such as Pavement Condition Index (PCI) or by a measure related to customer satisfaction such as the number of complaints per month about that certain road section. Or in the case of traffic level of service, it could be measured by the geometry of road or by travel time of the vehicles, which reflects the quality of traffic flow. So, levels of service can have multiple facets: customer satisfaction, environmental requirements and legal requirements.

Pavement crack refers to a variety of types of pavement distresses that occur on the surface of pavements. Different types of pavements develop different cracks. Type of cracking is also correlated with the type of climate and traffic. Sometimes the cracks are aggregated using an index such as Crack index, and sometimes they are merged with other distresses and are reported using Pavement Condition Index.

The rolling straight-edge is an instrument used to measure the surface regularity of roads and similar structures such as airport runways. It consists of a straightedge of a fixed distance mounted on wheels with a sensor at the centrepoint measuring deviation in height. It is rolled along the road surface and set to specific trigger levels which can be logged automatically or by means of an audible alarm. The rolling straight-edge was developed by the British Road Research Laboratory to replace earlier manual methods of measurement using rulers. It has been used by several countries and remains in use in the United Kingdom, Germany and Taiwan.

Granular base equivalency or granular base equivalence (GBE) is a measure of total pavement thickness. Since pavement is composed of multiple layers with different physical properties, its total thickness is measured by GBE. GBE translates the thickness of different road layers to a number using a set of coefficients. So, to calculate the GBE, the depth of each layer should be multiplied by the granular equivalency factor for the material in that layer. In the next step the sum of the converted layer thicknesses is calculated. This sum is called granular base equivalency, which is a popular and important measure in pavement design and pavement performance modeling.

The present serviceability index (PSI) is a pavement performance measure. Introduced by the American Association of State Highway and Transportation Officials (AASHTO), the PSI is one of the most widely used pavement performance indicators after pavement condition index (PCI) and international roughness index (IRI). This performance indicator ranges between 0 and 5, 0 representing a failed pavement and 5 an excellent one. Since the PSI entails slope variance, it is correlated with performance indicators related to roughness such as IRI.