A valve is a device or natural object that regulates, directs or controls the flow of a fluid by opening, closing, or partially obstructing various passageways. Valves are technically fittings, but are usually discussed as a separate category. In an open valve, fluid flows in a direction from higher pressure to lower pressure. The word is derived from the Latin valva, the moving part of a door, in turn from volvere, to turn, roll.

A diving cylinder or diving gas cylinder is a gas cylinder used to store and transport high pressure gas used in diving operations. This may be breathing gas used with a scuba set, in which case the cylinder may also be referred to as a scuba cylinder, scuba tank or diving tank. When used for an emergency gas supply for surface supplied diving or scuba, it may be referred to as a bailout cylinder or bailout bottle. It may also be used for surface-supplied diving or as decompression gas. A diving cylinder may also be used to supply inflation gas for a dry suit or buoyancy compensator. Cylinders provide gas to the diver through the demand valve of a diving regulator or the breathing loop of a diving rebreather.

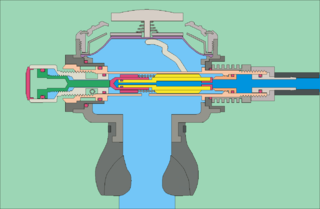

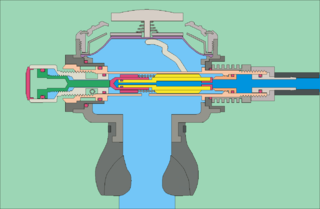

A diving regulator or underwater diving regulator is a pressure regulator that controls the pressure of breathing gas for underwater diving. The most commonly recognised application is to reduce pressurized breathing gas to ambient pressure and deliver it to the diver, but there are also other types of gas pressure regulator used for diving applications. The gas may be air or one of a variety of specially blended breathing gases. The gas may be supplied from a scuba cylinder carried by the diver, in which case it is called a scuba regulator, or via a hose from a compressor or high-pressure storage cylinders at the surface in surface-supplied diving. A gas pressure regulator has one or more valves in series which reduce pressure from the source, and use the downstream pressure as feedback to control the delivered pressure, or the upstream pressure as feedback to prevent excessive flow rates, lowering the pressure at each stage.

The GM Ecotec engine, also known by its codename L850, is a family of all-aluminium inline-four engines, displacing between 1.4 and 2.5 litres. Confusingly, the Ecotec name was also applied to both the Buick V6 Engine when used in Holden Vehicles, as well as the final DOHC derivatives of the previous GM Family II engine; the architecture was substantially re-engineered for this new Ecotec application produced since 2000. This engine family replaced the GM Family II engine, the GM 122 engine, the Saab H engine, and the Quad 4 engine. It is manufactured in multiple locations, to include Spring Hill Manufacturing, in Spring Hill, Tennessee, with engine blocks and cylinder heads cast at Saginaw Metal Casting Operations in Saginaw, Michigan.

A hose is a flexible hollow tube designed to carry fluids from one location to another. Hoses are also sometimes called pipes, or more generally tubing. The shape of a hose is usually cylindrical.

In automotive engineering, an exhaust manifold collects the exhaust gases from multiple cylinders into one pipe. The word manifold comes from the Old English word manigfeald and refers to the folding together of multiple inputs and outputs.

Ultra-high vacuum is the vacuum regime characterised by pressures lower than about 1×10−6 pascals. UHV conditions are created by pumping the gas out of a UHV chamber. At these low pressures the mean free path of a gas molecule is greater than approximately 40 km, so the gas is in free molecular flow, and gas molecules will collide with the chamber walls many times before colliding with each other. Almost all molecular interactions therefore take place on various surfaces in the chamber.

A gas cylinder is a pressure vessel for storage and containment of gases at above atmospheric pressure. High-pressure gas cylinders are also called bottles. Inside the cylinder the stored contents may be in a state of compressed gas, vapor over liquid, supercritical fluid, or dissolved in a substrate material, depending on the physical characteristics of the contents. A typical gas cylinder design is elongated, standing upright on a flattened bottom end, with the valve and fitting at the top for connecting to the receiving apparatus.

An inlet manifold or intake manifold is the part of an internal combustion engine that supplies the fuel/air mixture to the cylinders. The word manifold comes from the Old English word manigfeald and refers to the multiplying of one (pipe) into many.

An exhaust system is used to guide reaction exhaust gases away from a controlled combustion inside an engine or stove. The entire system conveys burnt gases from the engine and includes one or more exhaust pipes. Depending on the overall system design, the exhaust gas may flow through one or more of the following:

A solenoid valve is an electromechanically operated valve.

A surface condenser is a water-cooled shell and tube heat exchanger installed to condense exhaust steam from a steam turbine in thermal power stations. These condensers are heat exchangers which convert steam from its gaseous to its liquid state at a pressure below atmospheric pressure. Where cooling water is in short supply, an air-cooled condenser is often used. An air-cooled condenser is however, significantly more expensive and cannot achieve as low a steam turbine exhaust pressure as a water-cooled surface condenser.

A pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; hollow pipe is far stiffer per unit weight than solid members.

The SAE steel grades system is a standard alloy numbering system for steel grades maintained by SAE International.

A scuba manifold is a device incorporating one or more valves and one or more gas outlets with scuba regulator connections, used to connect two or more diving cylinders containing breathing gas, providing a greater amount of gas for longer dive times or deeper dives. An isolation manifold allows the connection between the cylinders to be closed in the case of a leak from one of the cylinders or its valve or regulator, conserving the gas in the other cylinder. Diving with two or more cylinders is often associated with technical diving. Almost all manifold assemblies include one cylinder valve for each cylinder, and the overwhelming majority are for two cylinders.

The Mitsubishi 4B1 engine is a range of all-alloy straight-4 piston engines built at Mitsubishi's Japanese "World Engine" powertrain plant in Shiga on the basis of the Global Engine Manufacturing Alliance (GEMA). Although the basic designs of the various engines are the same, their exact specifications are individually tailored for each partner. The cylinder block and other basic structural parts of the engine were jointly developed by the GEMA companies, but the intake and exhaust manifolds, the cylinder head's intake and exhaust ports, and other elements related to engine tuning were independently developed by Mitsubishi.

A fitting or adapter is used in pipe systems to connect sections of pipe or tube, adapt to different sizes or shapes, and for other purposes such as regulating fluid flow. These fittings are used in plumbing to manipulate the conveyance of fluids such as water for potatory, irrigational, sanitary, and refrigerative purposes, gas, petroleum, liquid waste, or any other liquid or gaseous substances required in domestic or commercial environments, within a system of pipes or tubes, connected by various methods, as dictated by the material of which these are made, the material being conveyed, and the particular environmental context in which they will be used, such as soldering, mortaring, caulking, Plastic welding, welding, friction fittings, threaded fittings, and compression fittings.

Orbital welding is a specialized area of welding whereby the arc is rotated mechanically through 360° around a static workpiece, an object such as a pipe, in a continuous process. The process was developed to address the issue of operator error in gas tungsten arc welding processes (GTAW), to support uniform welding around a pipe that would be significantly more difficult using a manual welding process, and to ensure high quality repeatable welds that would meet more stringent weld criteria set by ASME. In orbital welding, computer-controlled process runs with little intervention from the operator.

Corrosion monitoring is the use of a corrator or set of methods and equipment to provide offline or online information about corrosion rate expressed in mpy. - for better care and to take or improve preventive measures to combat and protect against corrosion. In this article, the difference between corrosion monitoring and corrosion protection, its difference with corrosion inspection and also the relationship between them, as well as online corrosion monitoring methods, equipment used and applications of each of them, are presented.

The mechanism of diving regulators is the arrangement of components and function of gas pressure regulators used in the systems which supply breathing gases for underwater diving. Both free-flow and demand regulators use mechanical feedback of the downstream pressure to control the opening of a valve which controls gas flow from the upstream, high-pressure side, to the downstream, low-pressure side of each stage. Flow capacity must be sufficient to allow the downstream pressure to be maintained at maximum demand, and sensitivity must be appropriate to deliver maximum required flow rate with a small variation in downstream pressure, and for a large variation in supply pressure, without instability of flow. Open circuit scuba regulators must also deliver against a variable ambient pressure. They must be robust and reliable, as they are life-support equipment which must function in the relatively hostile seawater environment, and the human interface must be comfortable over periods of several hours.