Related Research Articles

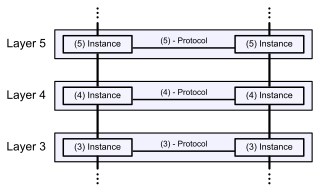

The Open Systems Interconnection model is a conceptual model that characterises and standardises the communication functions of a telecommunication or computing system without regard to its underlying internal structure and technology. Its goal is the interoperability of diverse communication systems with standard communication protocols.

In measurement technology and metrology, calibration is the comparison of measurement values delivered by a device under test with those of a calibration standard of known accuracy. Such a standard could be another measurement device of known accuracy, a device generating the quantity to be measured such as a voltage, a sound tone, or a physical artifact, such as a meter ruler.

The technical meaning of maintenance involves functional checks, servicing, repairing or replacing of necessary devices, equipment, machinery, building infrastructure, and supporting utilities in industrial, business, and residential installations. Over time, this has come to include multiple wordings that describe various cost-effective practices to keep equipment operational; these activities occur either before or after a failure.

ISO/IEC/IEEE 12207Systems and software engineering – Software life cycle processes is an international standard for software lifecycle processes. First introduced in 1995, it aims to be a primary standard that defines all the processes required for developing and maintaining software systems, including the outcomes and/or activities of each process.

Reliability engineering is a sub-discipline of systems engineering that emphasizes the ability of equipment to function without failure. Reliability describes the ability of a system or component to function under stated conditions for a specified period of time. Reliability is closely related to availability, which is typically described as the ability of a component or system to function at a specified moment or interval of time.

A piping and instrumentation diagram (P&ID) is a detailed diagram in the process industry which shows the piping and process equipment together with the instrumentation and control devices.

Integrated logistic support (ILS) is a technology in the system engineering to lower a product life cycle cost and decrease demand for logistics by the maintenance system optimization to ease the product support. Although originally developed for military purposes, it is also widely used in commercial customer service organisations.

IEC 61508 is an international standard published by the International Electrotechnical Commission consisting of methods on how to apply, design, deploy and maintain automatic protection systems called safety-related systems. It is titled Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems.

Asset management refers to a systematic approach to the governance and realization of value from the things that a group or entity is responsible for, over their whole life cycles. It may apply both to tangible assets and to intangible assets. Asset management is a systematic process of developing, operating, maintaining, upgrading, and disposing of assets in the most cost-effective manner.

Operations, administration and management or operations, administration and maintenance are the processes, activities, tools, and standards involved with operating, administering, managing and maintaining any system. This commonly applies to telecommunication, computer networks, and computer hardware.

ISO/IEC 17024: Conformity assessment - General requirements for bodies operating certification of persons is an International Standard which specifies criteria for the operation of a Personnel Certification Body. The standard includes requirements for the development and maintenance of the certification scheme for persons upon which the certification is based.

Transport standards organisations is an article transport Standards organisations, consortia and groups that are involved in producing and maintaining standards that are relevant to the global transport technology, transport journey planning and transport ticket/retailing industry. Transport systems are inherently distributed systems with complex information requirements. Robust modern standards for transport data are important for the safe and efficient operation of transport systems. These include:

Manufacturing execution systems (MES) are computerized systems used in manufacturing to track and document the transformation of raw materials to finished goods. MES provides information that helps manufacturing decision makers understand how current conditions on the plant floor can be optimized to improve production output. MES works as real time monitoring system to enable the control of multiple elements of the production process.

The Generating Availability Data System (GADS) is a database produced by the North American Electric Reliability Corporation (NERC). It includes annual summary reports comprising the statistics for power stations in the United States and Canada.

A drilling riser is a conduit that provides a temporary extension of a subsea oil well to a surface drilling facility. Drilling risers are categorised into two types: marine drilling risers used with subsea blowout preventer (BOP) and generally used by floating drilling vessels; and tie-back drilling risers used with a surface BOP and generally deployed from fixed platforms or very stable floating platforms like a spar or tension leg platform (TLP).

ISO 2146 is an ISO standard defining an information model for "registry services for libraries and related organisations". Operating at a higher level than item-level standards such as MARC, it takes as principal elements parties, collections, services and activities

Integrated vehicle health management (IVHM) or integrated system health management (ISHM) is the unified capability of systems to assess the current or future state of the member system health and integrate that picture of system health within a framework of available resources and operational demand.

Construction Operations Building Information Exchange (COBie) is a United States-based specification relating to managed asset information including space and equipment. It is closely associated with building information modeling (BIM) approaches to design, construction, and management of built assets.

ISO/IEC 27001 is an international standard on how to manage information security. The standard was originally published jointly by the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) in 2005 and then revised in 2013. It details requirements for establishing, implementing, maintaining and continually improving an information security management system (ISMS) – the aim of which is to help organizations make the information assets they hold more secure. A European update of the standard was published in 2017. Organizations that meet the standard's requirements can choose to be certified by an accredited certification body following successful completion of an audit. The effectiveness of the ISO/IEC 27001 certification process and the overall standard has been addressed in a recent large-scale study.

The Offshore and Onshore Reliability Data (OREDA) project was established in 1981 in cooperation with the Norwegian Petroleum Directorate. It is "one of the main reliability data sources for the oil and gas industry" and considered "a unique data source on failure rates, failure mode distribution and repair times for equipment used in the offshore industr[y]. OREDA's original objective was the collection of petroleum industry safety equipment reliability data. The current organization, as a cooperating group of several petroleum and natural gas companies, was established in 1983, and at the same time the scope of OREDA was extended to cover reliability data from a wide range of equipment used in oil and gas exploration and production (E&P). OREDA primarily covers offshore, subsea and topside equipment, but does also include some onshore E&P, and some downstream equipment as well.