A computer monitor is an output device that displays information in pictorial or textual form. A discrete monitor comprises a visual display, support electronics, power supply, housing, electrical connectors, and external user controls.

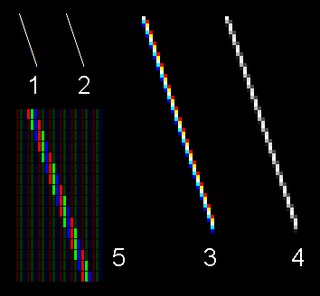

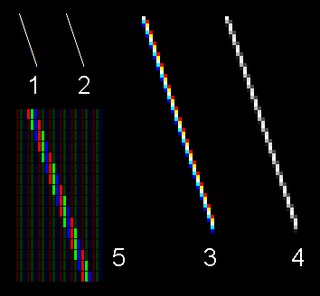

ClearType is Microsoft's implementation of subpixel rendering technology in rendering text in a font system. ClearType attempts to improve the appearance of text on certain types of computer display screens by sacrificing color fidelity for additional intensity variation. This trade-off is asserted to work well on LCD flat panel monitors.

Electronic paper or intelligent paper, is a display device that reflects ambient light, mimicking the appearance of ordinary ink on paper – unlike conventional flat-panel displays which need additional energy to emit their own light. This may make them more comfortable to read, and provide a wider viewing angle than most light-emitting displays. The contrast ratio in electronic displays available as of 2008 approaches newspaper, and newly developed displays are slightly better. An ideal e-paper display can be read in direct sunlight without the image appearing to fade.

A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that uses the light-modulating properties of liquid crystals combined with polarizers to display information. Liquid crystals do not emit light directly but instead use a backlight or reflector to produce images in color or monochrome.

Digital Visual Interface (DVI) is a video display interface developed by the Digital Display Working Group (DDWG). The digital interface is used to connect a video source, such as a video display controller, to a display device, such as a computer monitor. It was developed with the intention of creating an industry standard for the transfer of uncompressed digital video content.

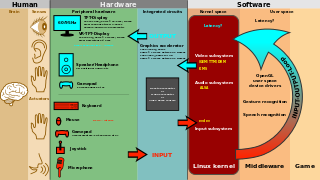

Usability can be described as the capacity of a system to provide a condition for its users to perform the tasks safely, effectively, and efficiently while enjoying the experience. In software engineering, usability is the degree to which a software can be used by specified consumers to achieve quantified objectives with effectiveness, efficiency, and satisfaction in a quantified context of use.

In computing, an icon is a pictogram or ideogram displayed on a computer screen in order to help the user navigate a computer system. The icon itself is a quickly comprehensible symbol of a software tool, function, or a data file, accessible on the system and is more like a traffic sign than a detailed illustration of the actual entity it represents. It can serve as an electronic hyperlink or file shortcut to access the program or data. The user can activate an icon using a mouse, pointer, finger, or voice commands. Their placement on the screen, also in relation to other icons, may provide further information to the user about their usage. In activating an icon, the user can move directly into and out of the identified function without knowing anything further about the location or requirements of the file or code.

Computer accessibility refers to the accessibility of a computer system to all people, regardless of disability type or severity of impairment. The term accessibility is most often used in reference to specialized hardware or software, or a combination of both, designed to enable the use of a computer by a person with a disability or impairment.

ISO 9241 is a multi-part standard from the International Organization for Standardization (ISO) covering ergonomics of human-system interaction and related, human-centered design processes. It is managed by the ISO Technical Committee 159. It was originally titled Ergonomic requirements for office work with visual display terminals (VDTs). From 2006 onwards, the standards were retitled to the more generic Ergonomics of Human System Interaction.

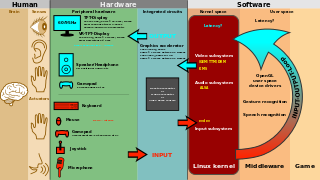

User interface (UI) design or user interface engineering is the design of user interfaces for machines and software, such as computers, home appliances, mobile devices, and other electronic devices, with the focus on maximizing usability and the user experience. In computer or software design, user interface (UI) design primarily focuses on information architecture. It is the process of building interfaces that clearly communicate to the user what's important. UI design refers to graphical user interfaces and other forms of interface design. The goal of user interface design is to make the user's interaction as simple and efficient as possible, in terms of accomplishing user goals. User-centered design is typically accomplished through the execution of modern design thinking which involves empathizing with the target audience, defining a problem statement, ideating potential solutions, prototyping wireframes, and testing prototypes in order to refine final interface mockups.

A glossy display is an electronic display with a glossy surface. In certain light environments, glossy displays provide better color intensity and contrast ratios than matte displays. The primary disadvantage of these displays is their tendency to reflect any external light, often resulting in an undesirable glare.

A monitor filter is an accessory to the computer display to filter out the light reflected from the smooth glass surface of a CRT or flat panel display. Many also include a ground to dissipate static buildup. A secondary use for monitor filters is privacy as they decrease the viewing angle of a monitor, preventing it from being viewed from the side; in this case, they are also called privacy screens.

A defective pixel or a dead pixel is a pixel on a liquid crystal display (LCD) that is not functioning properly. The ISO standard ISO 13406-2 distinguishes between three different types of defective pixels, while hardware companies tend to have further distinguishing types.

The viewing cone refers to the effective viewing directions of an LCD display, as seen from the eye. This collection of angles resembles a cone. The concept has been introduced as an international standard ISO 13406-2, which defines it as the range of viewing directions that can safely be used for the intended task without "reduced visual performance". This standard describes a complex procedure which evaluates the viewing cone from measurements of luminance and chromaticity versus direction of observation. ISO 13406-2 introduces 4 viewing direction range classes, from a wide viewing cone, for many simultaneous observers, to the so-called "privacy display", with a severely limited viewing cone. Compliance routes for different display applications can now be found in the successor standard ISO 9241-300.

An electronic visual display is a display device that can display images, video, or text that is transmitted electronically. Electronic visual displays include television sets, computer monitors, and digital signage. They are ubiquitous in mobile computing applications like tablet computers, smartphones, and information appliances. Many electronic visual displays are informally referred to as touch screens.

PenTile matrix is a family of patented subpixel matrix schemes used in electronic device displays. PenTile is a trademark of Samsung. PenTile matrices are used in AMOLED and LCD displays.

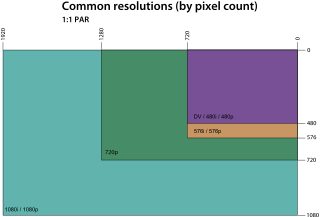

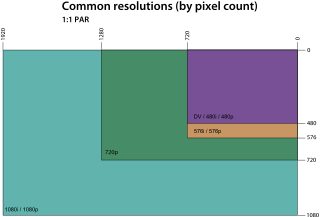

A display resolution standard is a commonly used width and height dimension of an electronic visual display device, measured in pixels. This information is used for electronic devices such as a computer monitor. Certain combinations of width and height are standardized and typically given a name and an initialism which is descriptive of its dimensions.

Lenovo Yoga is a line of consumer-oriented laptop computers, tablets, and all-in-one computers designed, developed and marketed by Lenovo, named for their ability to assume multiple form factors due to a hinged screen. The line currently competes against other 2-in-1 PCs such as the HP Spectre.

Ergonomics, also known as human factors or human factors engineering (HFE), is the application of psychological and physiological principles to the engineering and design of products, processes, and systems. Primary goals of human factors engineering are to reduce human error, increase productivity and system availability, and enhance safety, health and comfort with a specific focus on the interaction between the human and equipment.