This is an alphabetical list of articles pertaining specifically to mechanical engineering. For a broad overview of engineering, please see List of engineering topics. For biographies please see List of engineers.

Acceleration – Accuracy and precision – Actual mechanical advantage – Aerodynamics – Agitator (device) – Air handler – Air conditioner – Air preheater – Allowance – American Machinists' Handbook – American Society of Mechanical Engineers – Ampere – Applied mechanics – Antifriction – Archimedes' screw – Artificial intelligence – Automaton clock – Automobile – Automotive engineering – Axle – Air Compressor

Backlash – Balancing – Beale Number – Bearing – Belt (mechanical) – Bending – Biomechatronics – Bogie – Brittle – Buckling – Bus-- Bushing – Boilers & boiler systems BIW--

CAD – CAM – CAID – Calculator – Calculus – Car handling – Carbon fiber – Classical mechanics – Clean room design – Clock – Clutch – CNC – Coefficient of thermal expansion – Coil spring – Combustion – Composite material – Compression ratio – Compressive strength – Computational fluid dynamics – Computer – Computer-aided design – Computer-aided industrial design – Computer-numerically controlled – Conservation of mass – Constant-velocity joint – Constraint – Continuum mechanics – Control theory – Corrosion – Cotter pin – Crankshaft – Cybernetics –

Damping ratio – Deformation (engineering) – Delamination – Design – Diesel Engine – Differential – Dimensionless number – Diode – Diode laser – Drafting – Drifting – Driveshaft – Dynamics – Design for Manufacturability for CNC machining –

Elasticity – Elasticity tensor - Electric motor – Electrical engineering – Electrical circuit – Electrical network – Electromagnetism – Electronic circuit – Electronics – Energy – Engine – Engineering – Engineering cybernetics – Engineering drawing – Engineering economics – Engineering ethics – Engineering management – Engineering society – Exploratory engineering –

( Fits and tolerances)--- Factor of safety – False precision – Fast fracture – Fatigue – Fillet – Finite element analysis – Fluid mechanics – Flywheel – Force – Force density – Four-stroke cycle – Four wheel drive – Friction – Front wheel drive – Fundamentals of Engineering exam – Fusible plug – Fusion Deposition Modelling – forging

Gas compressor – Gauge – Gauge (engineering) – Gauge, rail – Gear – Gear coupling – Gear ratio – Granular material –

Heat engine – Heat transfer – Heating and cooling systems – Hinge – Hooke's law – Hotchkiss drive – HVAC – Hydraulics – Hydrostatics –

Ideal machine – Ideal mechanical advantage – Imperial College London – Inclined plane – Independent suspension – Inductor – Industrial engineering – Inertia – Institution of Mechanical Engineers – Instrumentation – Integrated circuit – Invention –

Joule – Junction

Laser – Leaf spring – Lever – Liability – Life cycle cost analysis – Limit state design – Live axle – Load transfer – Locomotive – Lubrication –

Machine – Machine learning – Magnetic circuit – Margin of safety – Mass transfer – Materials – Materials engineering – Material selection – Mechanical advantage – Mechanical Biological Treatment – Mechanical efficiency – Mechanical engineering – Mechanical equilibrium – Mechanical work – Mechanics – Mechanochemistry – Mechanosynthesis – Mechatronics – Micromachinery – Microprocessor – Microtechnology – modulus of rigidity-- Molecular assembler – Molecular nanotechnology – Moment – Moment of inertia – Motorcycle – Multi-link suspension

Pascal (unit) – Physics – Pinion – Piston – Pitch drop experiment – Plasma processing – Plasticity – Pneumatics – Poisson's ratio – Position vector – Potential difference – Power – Power stroke – Pressure – Prime mover – Process control – Product Lifecycle Management – Professional Engineer – Project management – Pulley – Pump –

Rack and pinion – Rack railway – Railcar – Rail gauge – Railroad car – Railroad switch – Rail tracks – Reaction kinetics – Rear wheel drive – Refrigeration – Reliability engineering – Relief valve – RepRap Project – Resistive force – Resistor – Reverse engineering – Rheology – Rigid body – Robotics – Roller chain – Rolling – Rotordynamics –

Safety engineering – Screw theory – Seal – Semiconductor – Series and parallel circuits – Shear force diagrams – Shear pin – Shear strength – Shear stress – Simple machine – Simulation – Six-stroke engine – Slide rule – Society of Automotive Engineers – Solid mechanics – Solid modeling – Sprung mass – Statics – Steering – Steam Systems – Stress–strain curve – Structural failure – Student Design Competition – Surveying – Suspension – Switch –

Technical drawing – Technology – Tensile strength – Tensile stress – Testing Adjusting Balancing – Theory of elasticity – Thermodynamics – Toe – Torque – Torsion beam suspension – Torsion spring – Toughness – Tramway track – Transmission – Truck – Truck (railway) – Turbine – Tribology – touch screen – tear – Tire manufacturing--

Understeer – Unibody – Unsprung weight –

Verification and Validation – Valve – Vector – Vertical strength – Viscosity – Volt – Vibration – Velocity diagrams –

Weapon - Wear – Wedge – Weight transfer – Wheel – Wheel and axle – Wheelset –

x bar charts

In continuum mechanics, stress is a physical quantity that describes forces present during deformation. For example, an object being pulled apart, such as a stretched elastic band, is subject to tensile stress and may undergo elongation. An object being pushed together, such as a crumpled sponge, is subject to compressive stress and may undergo shortening. The greater the force and the smaller the cross-sectional area of the body on which it acts, the greater the stress. Stress has dimension of force per area, with SI units of newtons per square meter (N/m2) or pascal (Pa).

Young's modulus is a mechanical property of solid materials that measures the tensile or compressive stiffness when the force is applied lengthwise. It is the modulus of elasticity for tension or axial compression. Young's modulus is defined as the ratio of the stress applied to the object and the resulting axial strain in the linear elastic region of the material.

In engineering and materials science, a stress–strain curve for a material gives the relationship between stress and strain. It is obtained by gradually applying load to a test coupon and measuring the deformation, from which the stress and strain can be determined. These curves reveal many of the properties of a material, such as the Young's modulus, the yield strength and the ultimate tensile strength.

In physics and materials science, elasticity is the ability of a body to resist a distorting influence and to return to its original size and shape when that influence or force is removed. Solid objects will deform when adequate loads are applied to them; if the material is elastic, the object will return to its initial shape and size after removal. This is in contrast to plasticity, in which the object fails to do so and instead remains in its deformed state.

The field of strength of materials typically refers to various methods of calculating the stresses and strains in structural members, such as beams, columns, and shafts. The methods employed to predict the response of a structure under loading and its susceptibility to various failure modes takes into account the properties of the materials such as its yield strength, ultimate strength, Young's modulus, and Poisson's ratio. In addition, the mechanical element's macroscopic properties such as its length, width, thickness, boundary constraints and abrupt changes in geometry such as holes are considered.

An elastic modulus is the unit of measurement of an object's or substance's resistance to being deformed elastically when a stress is applied to it.

In mechanics, compression is the application of balanced inward ("pushing") forces to different points on a material or structure, that is, forces with no net sum or torque directed so as to reduce its size in one or more directions. It is contrasted with tension or traction, the application of balanced outward ("pulling") forces; and with shearing forces, directed so as to displace layers of the material parallel to each other. The compressive strength of materials and structures is an important engineering consideration.

Stiffness is the extent to which an object resists deformation in response to an applied force.

Stress–strain analysis is an engineering discipline that uses many methods to determine the stresses and strains in materials and structures subjected to forces. In continuum mechanics, stress is a physical quantity that expresses the internal forces that neighboring particles of a continuous material exert on each other, while strain is the measure of the deformation of the material.

A beam is a structural element that primarily resists loads applied laterally across the beam's axis. Its mode of deflection is primarily by bending, as loads produce reaction forces at the beam's support points and internal bending moments, shear, stresses, strains, and deflections. Beams are characterized by their manner of support, profile, equilibrium conditions, length, and material.

In engineering, shear strength is the strength of a material or component against the type of yield or structural failure when the material or component fails in shear. A shear load is a force that tends to produce a sliding failure on a material along a plane that is parallel to the direction of the force. When a paper is cut with scissors, the paper fails in shear.

In materials science and engineering, the yield point is the point on a stress–strain curve that indicates the limit of elastic behavior and the beginning of plastic behavior. Below the yield point, a material will deform elastically and will return to its original shape when the applied stress is removed. Once the yield point is passed, some fraction of the deformation will be permanent and non-reversible and is known as plastic deformation.

This is an alphabetical list of articles pertaining specifically to structural engineering. For a broad overview of engineering, please see List of engineering topics. For biographies please see List of engineers.

This is an alphabetical list of articles pertaining specifically to Engineering Science and Mechanics (ESM). For a broad overview of engineering, please see Engineering. For biographies please see List of engineers and Mechanicians.

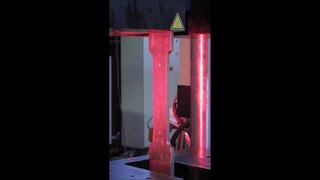

A universal testing machine (UTM), also known as a universal tester, universal tensile machine, materials testing machine, materials test frame, is used to test the tensile strength (pulling) and compressive strength (pushing), flexural strength, bending, shear, hardness, and torsion testing, providing valuable data for designing and ensuring the quality of materials. An earlier name for a tensile testing machine is a tensometer. The "universal" part of the name reflects that it can perform many standard tests application on materials, components, and structures.

This is an alphabetical list of articles pertaining specifically to civil engineering. For a broad overview of engineering, please see List of engineering topics. For biographies please see List of civil engineers.

Most of the terms listed in Wikipedia glossaries are already defined and explained within Wikipedia itself. However, glossaries like this one are useful for looking up, comparing and reviewing large numbers of terms together. You can help enhance this page by adding new terms or writing definitions for existing ones.

This glossary of civil engineering terms is a list of definitions of terms and concepts pertaining specifically to civil engineering, its sub-disciplines, and related fields. For a more general overview of concepts within engineering as a whole, see Glossary of engineering.

This glossary of engineering terms is a list of definitions about the major concepts of engineering. Please see the bottom of the page for glossaries of specific fields of engineering.