Mass production, also known as flow production or continuous production, is the production of substantial amounts of standardized products in a constant flow, including and especially on assembly lines. Together with job production and batch production, it is one of the three main production methods.

Albert Kahn was an American industrial architect. He was accredited the architect of Detroit and designed industrial plant complexes such as the Ford River Rouge automobile complex. He designed the construction of Detroit skyscrapers and office buildings as well as mansions in the city suburbs. He led an organization of hundreds of architect associates and in 1937, designed 19% of all architect-designed industrial factories in the United States. Under a unique contract in 1929, Kahn established a design and training office in Moscow, sending twenty-five staff there to train Soviet architects and engineers, and to design hundreds of industrial buildings under their first five-year plan. They trained more than 4,000 architects and engineers using Kahn's concepts. In 1943, the Franklin Institute posthumously awarded Kahn the Frank P. Brown Medal.

Flat Rock Assembly Plant, formerly known as Ford's Michigan Casting Center (MCC) (1972–81), Mazda Motor Manufacturing USA (1987–92) and AutoAlliance International (1992–2012), is a Ford Motor Company assembly plant located at 1 International Drive in Flat Rock, Michigan in Metro Detroit.

The Highland Park Ford Plant is a former Ford Motor Company factory located at 91 Manchester Avenue in Highland Park, Michigan. It was the second American production facility for the Model T automobile and the first factory in history to assemble cars on a moving assembly line. It became a National Historic Landmark in 1978.

The Henry Ford is a history museum complex in the Detroit suburb of Dearborn, Michigan, United States. The museum collection contains the presidential limousine of John F. Kennedy, Abraham Lincoln's chair from Ford's Theatre, Thomas Edison's laboratory, the Wright Brothers' bicycle shop, the Rosa Parks bus, and many other historical exhibits. It is the largest indoor–outdoor museum complex in the United States and is visited by over 1.7 million people each year. It was listed on the National Register of Historic Places in 1969 as Greenfield Village and Henry Ford Museum and designated a National Historic Landmark in 1981 as "Edison Institute".

The Ford Piquette Avenue Plant is a former factory located within the Milwaukee Junction area of Detroit, Michigan, in the United States. Built in 1904, it was the second center of automobile production for the Ford Motor Company, after the Ford Mack Avenue Plant. At the Piquette Avenue Plant, the company created and first produced the Ford Model T, the car credited with initiating the mass use of automobiles in the United States. Prior to the Model T, several other car models were assembled at the factory. Early experiments using a moving assembly line to make cars were also conducted there. It was also the first factory where more than 100 cars were assembled in one day. While it was headquartered at the Piquette Avenue Plant, Ford Motor Company became the biggest U.S.-based automaker, and it would remain so until the mid-1920s. The factory was used by the company until 1910, when its car production activity was relocated to the new, bigger Highland Park Ford Plant.

The Michoud Assembly Facility (MAF) is an 832-acre manufacturing complex owned by NASA in New Orleans East, a district within New Orleans, Louisiana, in the United States. Organizationally it is part of NASA's Marshall Space Flight Center, and is currently a multi-tenant complex to allow commercial and government contractors, as well as government agencies, to use the site.

Ford of Britain is a British wholly owned subsidiary of Ford Technologies Limited, itself a subsidiary of Ford International Capital LLC, which is a subsidiary of Ford Motor Company. Its business started in 1909 and has its registered office in Laindon, Essex. It adopted the name of Ford of Britain in 1960.

San Jose Assembly was a Ford Motor Company manufacturing site in Northern California, outside of San Jose in what is now the town of Milpitas. It was the automaker's primary factory in that region from 1955 to 1983, replacing the Richmond Assembly facility. Numerous vehicles were produced at the plant including the Ford Falcon, Ford Maverick and Ford Mustang. It was also the West Coast manufacturing location of the Ford Fairlane, Ford Torino, Ford Pinto, Ford Escort and the short lived Edsel Ranger and Edsel Pacer. Mercury products such as the Mustang-based Cougar, Montego, Comet, Bobcat, Capri and the Lynx were also assembled there. Ford F-series trucks were produced there, from shortly after the inception of the plant until its closure in 1983.

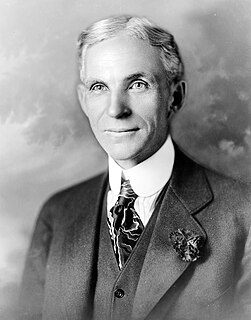

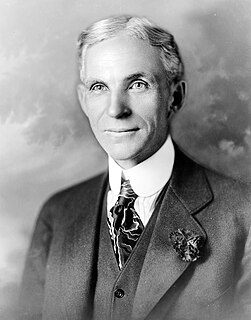

The Ford Motor Company is an American automaker, the world's fifth largest based on worldwide vehicle sales. Based in Dearborn, Michigan, a suburb of Detroit, it was founded by Henry Ford on June 16, 1903. Ford Motor Company would go on to become one of the largest and most profitable companies in the world, as well as being one of the few to survive the Great Depression. The largest family-controlled company in the world, the Ford Motor Company has been in continuous family control for over 110 years. Ford now encompasses two brands: Ford and Lincoln. Ford once owned 5 other luxury brands: Volvo, Land Rover, Jaguar, Aston Martin, and Mercury. Over time, those brands were sold to other companies and Mercury was discontinued.

Fiberfab was an American automotive manufacturer established in 1964. Starting with accessories and body parts, they progressed to making kit cars and fully assembled automobiles. They became one of the longest lasting kit car manufacturers.

Île Seguin is an island on the Seine river between Boulogne-Billancourt and Sèvres, in the west suburbs of Paris, France. It has a surface area of approximately 11.5 hectares, and is positioned opposite Meudon, a short distance downstream from the Île Saint-Germain. Administratively Meudon and the island are included as part of Boulogne-Billancourt, on the river's right bank, rather than of Sèvres on the left bank.

The Cuautitlan Stamping and Assembly Plant (CSAP) is a Ford Motor Company manufacturing facility located in Cuautitlán Izcalli, Mexico. The 202-acre (0.82 km2) site opened in 1964 and currently manufactures the Mustang Mach-E. The facility previously manufactured the Fiesta.

Ford Dagenham is a major automotive factory located in Dagenham, London, operated by the Ford of Britain subsidiary of Ford Motor Company. The plant opened in 1931 and has produced 10,980,368 cars and more than 39,000,000 engines in its history. It covers around 475 acres and has received over £800 million of capital investment since 2000.

Ford Motor Company is an American multinational automobile manufacturer headquartered in Dearborn, Michigan, United States. It was founded by Henry Ford and incorporated on June 16, 1903. The company sells automobiles and commercial vehicles under the Ford brand, and luxury cars under its Lincoln luxury brand. Ford also owns Brazilian SUV manufacturer Troller, an 8% stake in Aston Martin of the United Kingdom and a 32% stake in China's Jiangling Motors. It also has joint ventures in China, Taiwan, Thailand, Turkey, and Russia. The company is listed on the New York Stock Exchange and is controlled by the Ford family; they have minority ownership but the majority of the voting power.

Long Beach Assembly is a former Ford Motor Company assembly plant located at the Cerritos Channel on Terminal Island, at 700 Henry Ford Avenue in Long Beach, Southern California. It operated from 1930 through 1958.

Edison Assembly, also known as Metuchen Assembly, was a Ford Motor Company manufacturing plant in Edison, New Jersey. It was located at 939 U.S. Route 1 and occupied over 100 acres when it was open. The factory began operations in 1948 and was closed in 2004. Several popular Ford products were manufactured there, such as the Ford Mustang, Ford Ranger, and the Ford Pinto. When the plant opened, it manufactured the new Mercury branded and Lincoln vehicles. It was one of three Ford manufacturing facilities in New Jersey and was built two years before the Mahwah Assembly plant was opened in 1950.

The Ford Pilot Plant facility, located at 17000 Oakwood Boulevard in Allen Park, Michigan, was opened in the summer of 1956 as the original location for the newly created Continental Division, where all Continental Mark II cars were assembled. It was renamed the Edsel Division Headquarters until 1959, when Edsel was discontinued and later became the New Model Programs Development Center facility, where new models are tested and developed. The role of the pilot plant is to test manufacture new products for the first time, documenting the steps and procedures, before assembly line production begins at the designated factory. The location can manufacture several vehicles at one time, where products are moved from station to station on mobile carriages until the process is complete.

Henry Ford & Sons Limited is the Irish subsidiary of the United States-based automaker Ford Motor Company. With an assembly plant for motor vehicles, it was part of the automotive industry in Ireland.