Engineering statistics combines engineering and statistics using scientific methods for analyzing data. Engineering statistics involves data concerning manufacturing processes such as: component dimensions, tolerances, type of material, and fabrication process control. There are many methods used in engineering analysis and they are often displayed as histograms to give a visual of the data as opposed to being just numerical. Examples of methods are:

- Design of Experiments (DOE) is a methodology for formulating scientific and engineering problems using statistical models. The protocol specifies a randomization procedure for the experiment and specifies the primary data-analysis, particularly in hypothesis testing. In a secondary analysis, the statistical analyst further examines the data to suggest other questions and to help plan future experiments. In engineering applications, the goal is often to optimize a process or product, rather than to subject a scientific hypothesis to test of its predictive adequacy. The use of optimal designs reduces the cost of experimentation.

- Quality control and process control use statistics as a tool to manage conformance to specifications of manufacturing processes and their products.

- Time and methods engineering use statistics to study repetitive operations in manufacturing in order to set standards and find optimum manufacturing procedures.

- Reliability engineering which measures the ability of a system to perform for its intended function and has tools for improving performance.

- Probabilistic design involving the use of probability in product and system design

- System identification uses statistical methods to build mathematical models of dynamical systems from measured data. System identification also includes the optimal design of experiments for efficiently generating informative data for fitting such models.

Systems engineering is an interdisciplinary field of engineering and engineering management that focuses on how to design and manage complex systems over their life cycles. At its core, systems engineering utilizes systems thinking principles to organize this body of knowledge. The individual outcome of such efforts, an engineered system, can be defined as a combination of components that work in synergy to collectively perform a useful function.

PTC Creo, formerly known as Pro/ENGINEER and Wildfire, is a 3D CAD, CAM, CAE, and associative solid modelling app. It is one of a suite of 10 collaborative applications that provide solid modelling, assembly modelling, 2D orthographic views, finite element analysis, direct and parametric modelling, sub-divisional and NURBS surface modelling, and NC and tooling functionality for mechanical designers. Creo Elements/Parametric compete directly with Solidworks, CATIA, and NX/Solid Edge. It was created by Parametric Technology Corporation (PTC) and was the first of its kind to market.

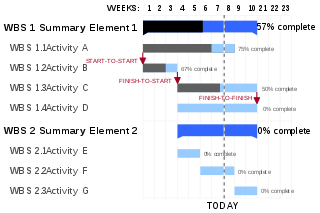

Henry Laurence Gantt, A.B., M.E. was an American mechanical engineer and management consultant who is best known for his work in the development of scientific management. He created the Gantt chart in the 1910s.

Engineering management is the application of the practice of management to the practice of engineering.

Statistical process control (SPC) is a method of quality control which employs statistical methods to monitor and control a process. This helps to ensure that the process operates efficiently, producing more specification-conforming products with less waste. SPC can be applied to any process where the "conforming product" output can be measured. Key tools used in SPC include run charts, control charts, a focus on continuous improvement, and the design of experiments. An example of a process where SPC is applied is manufacturing lines.

In industry, product lifecycle management (PLM) is the process of managing the entire lifecycle of a product from inception, through engineering design and manufacture, to service and disposal of manufactured products. PLM integrates people, data, processes and business systems and provides a product information backbone for companies and their extended enterprise.

Process engineering is the understanding and application of the fundamental principles and laws of nature that allow us to transform raw material and energy into products that are useful to society, an industrial level. By taking advantage of the driving forces of nature such as pressure, temperature and concentration gradients, as well as the law of conservation of mass, process engineers can develop methods to synthesize and purify large quantities of desired chemical products. Process engineering focuses on the design, operation, control, optimization and intensification of chemical, physical, and biological processes. Process engineering encompasses a vast range of industries, such as agriculture, automotive, biotechnical, chemical, food, material development, mining, nuclear, petrochemical, pharmaceutical, and software development. The application of systematic computer-based methods to process engineering is "process systems engineering".

Business process modeling (BPM) in business process management and systems engineering is the activity of representing processes of an enterprise, so that the current process may be analysed, improved, and automated. BPM is typically performed by business analysts, who provide expertise in the modeling discipline; by subject matter experts, who have specialized knowledge of the processes being modelled; or more commonly by a team comprising both. Alternatively, the process model can be derived directly from events' logs using process mining tools.

A design engineer is a person who may be involved in any of various engineering disciplines including civil, mechanical, electrical, chemical, textiles, aerospace, nuclear, manufacturing, systems, and structural /building/architectural. Design engineers tend to work on products and systems that involve adapting and using complex scientific and mathematical techniques. The emphasis tends to be on utilizing engineering physics and sciences to develop solutions for society.

Operations management is an area of management concerned with designing and controlling the process of production and redesigning business operations in the production of goods or services. It involves the responsibility of ensuring that business operations are efficient in terms of using as few resources as needed and effective in terms of meeting customer requirements. Operations management is primarily concerned with planning, organizing and supervising in the contexts of production, manufacturing or the provision of services.

Computer-aided production engineering (CAPE) is a relatively new and significant branch of engineering. Global manufacturing has changed the environment in which goods are produced. Meanwhile, the rapid development of electronics and communication technologies has required design and manufacturing to keep pace.

Scheduling is the process of arranging, controlling and optimizing work and workloads in a production process or manufacturing process. Scheduling is used to allocate plant and machinery resources, plan human resources, plan production processes and purchase materials.

The following outline is provided as an overview of and topical guide to management:

The engineering design process is a methodical series of steps that engineers use in creating functional products and processes. The process is highly iterative - parts of the process often need to be repeated many times before another can be entered - though the part(s) that get iterated and the number of such cycles in any given project may vary.

…It is a decision making process in which the basic sciences, mathematics, and engineering sciences are applied to convert resources optimally to meet a stated objective. Among the fundamental elements of the design process are the establishment of objectives and criteria, synthesis, analysis, construction, testing and evaluation.

For the application of engineering economics in the practice of civil engineering see Engineering economics.

Industrial and Production Engineering (IPE) is an interdisciplinary engineering discipline that includes manufacturing technology, engineering sciences, management science, and optimization of complex processes, systems, or organizations. It is concerned with the understanding and application of Engineering Procedures in Manufacturing Processes and Production Methods. Industrial Engineering dates back all the way to the industrial revolution, initiated in 1700s by Sir Adam Smith, Henry Ford, Eli Whitney, Frank Gilbreth and Lilian Gilbreth, Henry Gantt, F.W. Taylor, etc. After the 1970s, industrial and production engineering developed worldwide and started to widely use automation and robotics. Industrial and production Engineering includes three areas: Mechanical Engineering, Industrial Engineering, and Management Science. The main objective for people within this discipline is to improve efficiency, drive up effectiveness of manufacturing, quality control, and to reduce cost while making their products more attractive and marketable. Industrial engineering is concerned with the development, improvement, and implementation of integrated systems of people, money, knowledge, information, equipment, energy, materials, as well as analysis and synthesis. The principles of IPE include mathematical, physical and social sciences and methods of engineering design to specify, predict, and evaluate the results to be obtained from the systems or processes currently in place or being developed. The target of production engineering is to complete the production process in the smoothest, most-judicious and most-economic way. Production engineering also overlaps substantially with manufacturing engineering and industrial engineering. The concept of production engineering is interchangeable with manufacturing engineering.

Charles Day was an American electrical, construction and consulting engineer, and co-founder of Day & Zimmermann. He is known as a specialist in public utility management and operation, and for his seminal contributions to flow charts and the routing diagram.