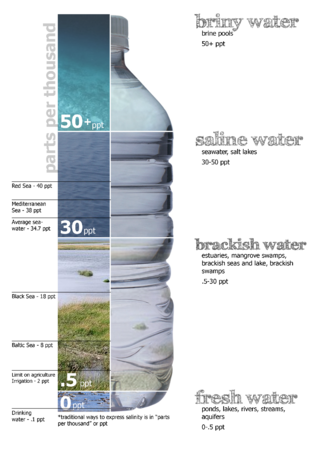

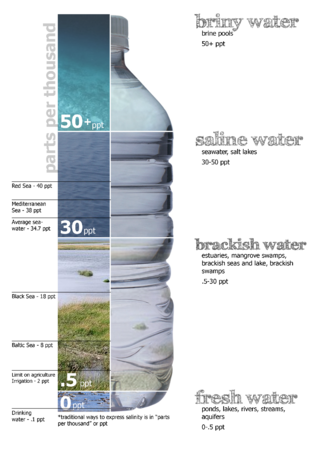

Brine is water with a high-concentration solution of salt. In diverse contexts, brine may refer to the salt solutions ranging from about 3.5% up to about 26%. Brine forms naturally due to evaporation of ground saline water but it is also generated in the mining of sodium chloride. Brine is used for food processing and cooking, for de-icing of roads and other structures, and in a number of technological processes. It is also a by-product of many industrial processes, such as desalination, so it requires wastewater treatment for proper disposal or further utilization.

Desalination is a process that takes away mineral components from saline water. More generally, desalination is the removal of salts and minerals from a target substance, as in soil desalination, which is an issue for agriculture. Saltwater is desalinated to produce water suitable for human consumption or irrigation. The by-product of the desalination process is brine. Desalination is used on many seagoing ships and submarines. Most of the modern interest in desalination is focused on cost-effective provision of fresh water for human use. Along with recycled wastewater, it is one of the few rainfall-independent water resources.

Microfiltration is a type of physical filtration process where a contaminated fluid is passed through a special pore-sized membrane filter to separate microorganisms and suspended particles from process liquid. It is commonly used in conjunction with various other separation processes such as ultrafiltration and reverse osmosis to provide a product stream which is free of undesired contaminants.

Forward osmosis (FO) is an osmotic process that, like reverse osmosis (RO), uses a semi-permeable membrane to effect separation of water from dissolved solutes. The driving force for this separation is an osmotic pressure gradient, such that a "draw" solution of high concentration, is used to induce a net flow of water through the membrane into the draw solution, thus effectively separating the feed water from its solutes. In contrast, the reverse osmosis process uses hydraulic pressure as the driving force for separation, which serves to counteract the osmotic pressure gradient that would otherwise favor water flux from the permeate to the feed. Hence significantly more energy is required for reverse osmosis compared to forward osmosis.

physical plant, mechanical plant or industrial plant refers to the necessary infrastructure used in operation and maintenance of a given facility. The operation of these facilities, or the department of an organization which does so, is called "plant operations" or facility management. Industrial plant should not be confused with "manufacturing plant" in the sense of "a factory". This is a holistic look at the architecture, design, equipment, and other peripheral systems linked with a plant required to operate or maintain it.

A reverse osmosis plant is a manufacturing plant where the process of reverse osmosis takes place. Reverse osmosis is a common process to purify or desalinate contaminated water by forcing water through a membrane. Water produced by reverse osmosis may be used for a variety of purposes, including desalination, wastewater treatment, concentration of contaminants, and the reclamation of dissolved minerals. An average modern reverse osmosis plant needs six kilowatt-hours of electricity to desalinate one cubic metre of water. The process also results in an amount of salty briny waste. The challenge for these plants is to find ways to reduce energy consumption, use sustainable energy sources, improve the process of desalination and to innovate in the area of waste management to deal with the waste. Self-contained water treatment plants using reverse osmosis, called reverse osmosis water purification units, are normally used in a military context.

A solar-powered desalination unit produces potable water from saline water through direct or indirect methods of desalination powered by sunlight. Solar energy is the most promising renewable energy source due to its ability to drive the more popular thermal desalination systems directly through solar collectors and to drive physical and chemical desalination systems indirectly through photovoltaic cells.

Richard Lindsay Stover, Ph.D., pioneered the development of the PX Pressure Exchanger energy recovery device Energy recovery that is currently in use in most seawater reverse osmosis desalination plants in existence today.

Reverse osmosis (RO) is a water purification process that uses a semi-permeable membrane to separate water molecules from other substances. RO applies pressure to overcome osmotic pressure that favors even distributions. RO can remove dissolved or suspended chemical species as well as biological substances, and is used in industrial processes and the production of potable water. RO retains the solute on the pressurized side of the membrane and the purified solvent passes to the other side. It relies on the relative sizes of the various molecules to decide what passes through. "Selective" membranes reject large molecules, while accepting smaller molecules.

Water supply and sanitation in Israel are intricately linked to the historical development of Israel. Because rain falls only in the winter, and largely in the northern part of the country, irrigation and water engineering are considered vital to the country's economic survival and growth. Large scale projects to desalinate seawater, direct water from rivers and reservoirs in the north, make optimal use of groundwater, and reclaim flood overflow and sewage have been undertaken. Among them is the National Water Carrier, carrying water from the country's biggest freshwater lake, the Sea of Galilee, to the northern part of the Negev desert through channels, pipes and tunnels. Israel's water demand today outstrips available conventional water resources. Thus, in an average year, Israel relies for about half of its water supply on unconventional water resources, including reclaimed water and desalination. A particularly long drought in 1998–2002 had prompted the government to promote large-scale seawater desalination. In 2022, 85% of the country's drinkable water was produced through desalination of saltwater and brackish water.

The Adelaide Desalination plant (ADP), formerly known as the Port Stanvac Desalination Plant, is a sea water reverse osmosis desalination plant located in Lonsdale, South Australia which has the capacity to provide the city of Adelaide with up to 50% of its drinking water needs.

A membrane is a selective barrier; it allows some things to pass through but stops others. Such things may be molecules, ions, or other small particles. Membranes can be generally classified into synthetic membranes and biological membranes. Biological membranes include cell membranes ; nuclear membranes, which cover a cell nucleus; and tissue membranes, such as mucosae and serosae. Synthetic membranes are made by humans for use in laboratories and industry.

Degrémont is a company specializing in the production of drinking water, and in the treatment of sewage and sludge. After starting as a family business in France in 1939, it has since become a subsidiary of Suez Environment, employing 4,600 people in 70 countries, and generating annual revenues of €1.520 billion.

Australia is the driest habitable continent on Earth and its installed desalination capacity has been increasing. Until a few decades ago, Australia met its demands for water by drawing freshwater from dams and water catchments. As a result of the water supply crisis during the severe 1997–2009 drought, state governments began building desalination plants that purify seawater using reverse osmosis technology. Approximately one percent of the world's drinkable water originates from desalination plants.

Chennai Metropolitan Water Supply and Sewerage Board, known shortly as CMWSSB, is a statutory board of Government of Tamil Nadu which provides water supply and sewage treatment to the city of Chennai and its metropolitan region.

The Minjur Desalination Plant is a reverse osmosis, water desalination plant at Kattupalli village, a northern suburb of Chennai, India, on the coast of the Bay of Bengal that supplies water to the city of Chennai. Built on a 60-acre site, it is the largest desalination plant in India. Construction works were carried out by the Indian company IVRCL and the Spanish company Abengoa, under the direction of the Project Manager Fernando Portillo Vallés and the Construction Manager Juan Ignacio Jiménez-Velasco, who returned to Europe after the inauguration of the plant to work on renewable energy projects. Originally scheduled to be operational by January 2009, the work on the plant was delayed due to Cyclone Nisha in October 2008, which damaged a portion of the completed marine works and destroyed the cofferdam meant for the installation of transition pipes. The trial runs were completed in June 2010 and the plant was opened in July 2010. Water from the plant will be utilised chiefly for industrial purposes such as the Ennore Port and North Chennai Thermal Power Station. However, during droughts, water from the plant will be supplied to the public, serving an estimated population of 1,000,000.

The coastal city of Chennai has a metropolitan population of 10.6 million as per 2019 census. As the city lacks a perennial water source, catering the water requirements of the population has remained an arduous task. On 18 June 2019, the city's reservoirs ran dry, leaving the city in severe crisis.

Aquaver is a cleantech company headquartered in Voorburg, Netherlands, with offices at the High Tech Campus Eindhoven. Aquaver is acknowledged to be the first company worldwide to develop commercial systems based on membrane distillation, a novel technology for water treatment.

There are approximately 16,000 operational desalination plants, located across 177 countries, which generate an estimated 95 million m3/day of fresh water. Micro desalination plants operate near almost every natural gas or fracking facility in the United States. Furthermore, micro desalination facilities exist in textile, leather, food industries, etc.