Castlefield is an inner-city conservation area in Manchester, North West England. The conservation area which bears its name is bounded by the River Irwell, Quay Street, Deansgate and Chester Road. It was the site of the Roman era fort of Mamucium or Mancunium which gave its name to Manchester. It was the terminus of the Bridgewater Canal, the world's first industrial canal, built in 1764; the oldest canal warehouse opened in 1779. The world's first passenger railway terminated here in 1830, at Liverpool Road railway station and the first railway warehouse opened here in 1831.

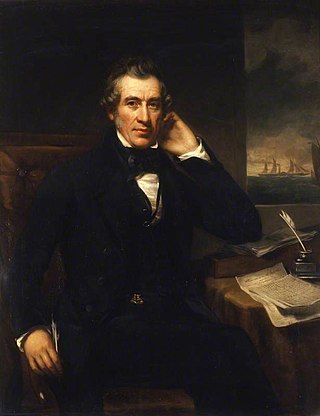

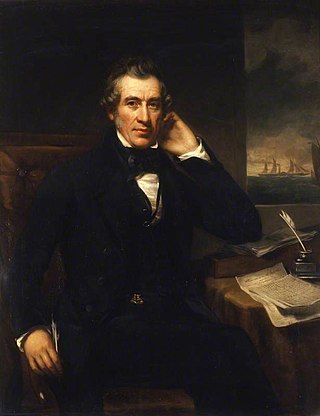

Sir William Fairbairn, 1st Baronet of Ardwick was a Scottish civil engineer, structural engineer and shipbuilder. In 1854 he succeeded George Stephenson and Robert Stephenson to become the third president of the Institution of Mechanical Engineers.

A cotton mill is a building that houses spinning or weaving machinery for the production of yarn or cloth from cotton, an important product during the Industrial Revolution in the development of the factory system.

Textile manufacture during the British Industrial Revolution was centred in south Lancashire and the towns on both sides of the Pennines in the United Kingdom. The main drivers of the Industrial Revolution were textile manufacturing, iron founding, steam power, oil drilling, the discovery of electricity and its many industrial applications, the telegraph and many others. Railroads, steamboats, the telegraph and other innovations massively increased worker productivity and raised standards of living by greatly reducing time spent during travel, transportation and communications.

The Hat Works is a museum in Stockport, Greater Manchester, England, which opened in 2000. Before that, smaller displays of hatting equipment were exhibited in Stockport Museum and in the former Battersby hat factory.

Murrays' Mills is a complex of former cotton mills on land between Jersey Street and the Rochdale Canal in the district of Ancoats, Manchester, England. The mills were built for brothers Adam and George Murray.

Brunswick Mill, Ancoats is a former cotton spinning mill on Bradford Road in Ancoats, Manchester, England. The mill was built around 1840, part of a group of mills built along the Ashton Canal, and at that time it was one of the country's largest mills. It was built round a quadrangle, a seven-storey block facing the canal. It was taken over by the Lancashire Cotton Corporation in the 1930s and passed to Courtaulds in 1964. Production finished in 1967.

Palmer Mills were cotton spinning mills in Portwood, Stockport, Greater Manchester, England. Built in the late 19th century, they were taken over by the Lancashire Cotton Corporation in the 1930s and sold on. Renamed the Stockport Paper Mill, they survived into the 21st century when they were demolished to be replaced by modern businesses.

Saxon Mill, Droylsden was a cotton spinning mill in Droylsden, Tameside, Greater Manchester, England. It was built in the 1907, taken over by the Lancashire Cotton Corporation in the 1930s and passed to Courtaulds in 1964. Production finished in 1967, and the mill was demolished in 1995.

Harp Mill was a former cotton spinning mill in the Castleton, Rochdale, Greater Manchester, England. Queensway, Castleton was a hub of cotton mills including the three 't', Th'Arrow, Th'Harp, and Th'Ensor. The 1908 Castleton map includes: Marland Cotton Mill, Castleton Cotton Mill, Globe Works, Arrow Cotton Mill, Harp Cotton Mill, Globe Leather Works, Castleton Size Works and Castleton Iron Works. Th'Harp was built in 1908 for the Harp Doubling Company and was taken over by the Lancashire Cotton Corporation in 1938. The mill closed in 1958, and was sold to the hosiery manufacturer N. Corah Ltd.

Mars Mill was a former cotton spinning mill in Castleton, Rochdale, Greater Manchester, England. Castleton joined the Borough of Rochdale in 1899. Queensway, Castleton was a hub of cotton mills; Mars, Marland, and Castleton Mill were a group of three. It was taken over by the Lancashire Cotton Corporation in 1935 and passed to Courtaulds in 1964 and demolished in the 1990s; Marland survived until 2004.

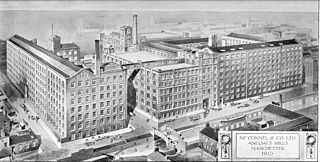

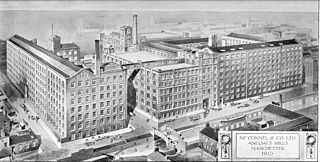

McConnel & Kennedy Mills are a group of cotton mills on Redhill Street in Ancoats, Manchester, England. With the adjoining Murrays' Mills, they form a nationally important group.

The Weavers' Triangle is an area of Burnley in Lancashire, England consisting mostly of 19th-century industrial buildings at the western side of town centre clustered around the Leeds and Liverpool Canal. The area has significant historic interest as the cotton mills and associated buildings encapsulate the social and economic development of the town and its weaving industry. From the 1980s, the area has been the focus of major redevelopment efforts.

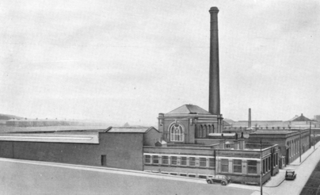

Ellenroad Mill was a cotton spinning mill in Newhey, a village in the Milnrow area of Rochdale, England. It was built as a mule spinning mill in 1890 by Stott and Sons and extended in 1899. It was destroyed by fire on 19 January 1916. When it was rebuilt, it was designed and equipped as a ring spinning mill.

Royal Mill, which is located on the corner of Redhill Street and Henry Street, Ancoats, in Manchester, England, is an early-20th-century cotton mill, one of the last of "an internationally important group of cotton-spinning mills" sited in East Manchester. Royal Mill was constructed in 1912 on part of the site of the earlier McConnel & Kennedy mills, established in 1798. It was originally called New Old Mill and was renamed following a royal visit by King George VI and Queen Elizabeth in 1942. A plaque commemorates the occasion. The Ancoats mills collectively comprise "the best and most-complete surviving examples of early large-scale factories concentrated in one area".

Clarence Mill is a five-storey former cotton spinning mill in Bollington, Cheshire, in England. It was built between 1834 and 1877 for the Swindells family of Bollington. It was built alongside the Macclesfield Canal, which opened in 1831.

A weaving shed is a distinctive type of mill developed in the early 1800s in Lancashire, Derbyshire and Yorkshire to accommodate the new power looms weaving cotton, silk, woollen and worsted. A weaving shed can be a stand-alone mill, or a component of a combined mill. Power looms cause severe vibrations requiring them to be located on a solid ground floor. In the case of cotton, the weaving shed needs to remain moist. Maximum daylight is achieved, by the sawtooth "north-facing roof lights".

Kearsley Mill is a 240,000 sq ft (22,000 m2), late period cotton mill located in the small village of Prestolee in Kearsley, Greater Manchester, part of the historic county of Lancashire. A near complete example of Edwardian mill architecture, the building now functions as headquarters for a number of businesses and is still used in the continued manufacturing and distribution of textiles by Richard Haworth Ltd Est (1876), part of the Ruia Group. The mill is a Grade II listed building.

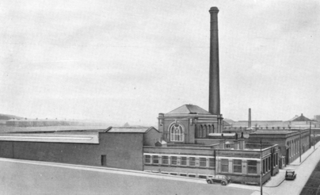

Wear Mill was an integrated cotton works on the Cheadle Heath bank of the River Mersey in Stockport, Greater Manchester, in England. It was started around 1790 and added to, particularly in 1831 and 1884. In 1840, the Stockport Viaduct was built over the river and over Wear Mill.

Mather Lane Mills was a complex of cotton mills built by the Bridgewater Canal in Bedford, Leigh in Lancashire, England. The No 2 mill and its former warehouse are grade II listed buildings.