The timeline of underwater diving technology is a chronological list of notable events in the history of the development of underwater diving equipment. With the partial exception of breath-hold diving, the development of underwater diving capacity, scope, and popularity, has been closely linked to available technology, and the physiological constraints of the underwater environment.

Aqua-Lung was the first open-circuit, self-contained underwater breathing apparatus to achieve worldwide popularity and commercial success. This class of equipment is now commonly referred to as a twin-hose diving regulator, or demand valve. The Aqua-Lung was invented in France during the winter of 1942–1943 by two Frenchmen: engineer Émile Gagnan and Jacques Cousteau, who was a Naval Lieutenant. It allowed Cousteau and Gagnan to film and explore underwater more easily.

CCM Hockey is a Canadian brand of ice hockey equipment owned by Birch Hill Equity Partners through its portfolio company Sport Maska Inc. The history of the brand traces to 1905, when Canada Cycle and Motor Limited, founded in 1899, began manufacturing hockey equipment as a secondary business. After Canada Cycle went bankrupt in 1982, it sold off its cycling and hockey divisions to separate owners. The hockey division was acquired by Sport Maska, a Quebec-based manufacturer of jerseys.

A diving regulator or underwater diving regulator is a pressure regulator that controls the pressure of breathing gas for underwater diving. The most commonly recognised application is to reduce pressurized breathing gas to ambient pressure and deliver it to the diver, but there are also other types of gas pressure regulator used for diving applications. The gas may be air or one of a variety of specially blended breathing gases. The gas may be supplied from a scuba cylinder carried by the diver, in which case it is called a scuba regulator, or via a hose from a compressor or high-pressure storage cylinders at the surface in surface-supplied diving. A gas pressure regulator has one or more valves in series which reduce pressure from the source, and use the downstream pressure as feedback to control the delivered pressure, or the upstream pressure as feedback to prevent excessive flow rates, lowering the pressure at each stage.

Standard diving dress, also known as hard-hat or copper hat equipment, deep sea diving suit or heavy gear, is a type of diving suit that was formerly used for all relatively deep underwater work that required more than breath-hold duration, which included marine salvage, civil engineering, pearl shell diving and other commercial diving work, and similar naval diving applications. Standard diving dress has largely been superseded by lighter and more comfortable equipment.

Surface-supplied diving is a mode of underwater diving using equipment supplied with breathing gas through a diver's umbilical from the surface, either from the shore or from a diving support vessel, sometimes indirectly via a diving bell. This is different from scuba diving, where the diver's breathing equipment is completely self-contained and there is no essential link to the surface. The primary advantages of conventional surface supplied diving are lower risk of drowning and considerably larger breathing gas supply than scuba, allowing longer working periods and safer decompression. Disadvantages are the absolute limitation on diver mobility imposed by the length of the umbilical, encumbrance by the umbilical, and high logistical and equipment costs compared with scuba. The disadvantages restrict use of this mode of diving to applications where the diver operates within a small area, which is common in commercial diving work.

A diving helmet is a rigid head enclosure with a breathing gas supply used in underwater diving. They are worn mainly by professional divers engaged in surface-supplied diving, though some models can be used with scuba equipment. The upper part of the helmet, known colloquially as the hat or bonnet, may be sealed directly to the diver using a neck dam, connected to a diving suit by a lower part, known as a breastplate, or corselet, depending on regional language preferences, or simply rest on the diver's shoulders, with an open bottom, for shallow water use.

A full-face diving mask is a type of diving mask that seals the whole of the diver's face from the water and contains a mouthpiece, demand valve or constant flow gas supply that provides the diver with breathing gas. The full face mask has several functions: it lets the diver see clearly underwater, it provides the diver's face with some protection from cold and polluted water and from stings, such as from jellyfish or coral. It increases breathing security and provides a space for equipment that lets the diver communicate with the surface support team.

Christian Augustus Siebe was a British engineer chiefly known for his contributions to diving equipment.

Dräger is a German company based in Lübeck which makes breathing and protection equipment, gas detection and analysis systems, and noninvasive patient monitoring technologies. Customers include hospitals, fire departments and diving companies.

Heinke was a series of companies that made diving equipment in London, run by members of a Heinke family.

DESCO is an underwater diving equipment maker which was first organized in 1937 in Milwaukee, Wisconsin as Diving Equipment and Salvage Co.

A diver's pump is a manually operated low pressure air compressor used to provide divers in standard diving dress with air while they are underwater.

Maurice Fernez was a French inventor and pioneer in the field of underwater breathing apparatus, respirators and gas masks. He was pivotal in the transition of diving from the tethered diving helmet and suit of the nineteenth century to the free diving with self-contained equipment of the twentieth century. All Fernez invented apparatus were surface-supplied but his inventions, especially his mouthpiece equipped with a one-way valve, inspired the scuba diving pioneer Yves le Prieur. He was also a talented businessman who created a company to manufacture and sell the breathing apparatus he invented, and expanded its range of products to include gas masks, respirators and filters.

JFD is a subsidiary of James Fisher & Sons is a Scottish provider of diving equipment and related services.

The history of underwater diving starts with freediving as a widespread means of hunting and gathering, both for food and other valuable resources such as pearls and coral. By classical Greek and Roman times commercial applications such as sponge diving and marine salvage were established. Military diving also has a long history, going back at least as far as the Peloponnesian War, with recreational and sporting applications being a recent development. Technological development in ambient pressure diving started with stone weights (skandalopetra) for fast descent. In the 16th and 17th centuries diving bells became functionally useful when a renewable supply of air could be provided to the diver at depth, and progressed to surface-supplied diving helmets—in effect miniature diving bells covering the diver's head and supplied with compressed air by manually operated pumps—which were improved by attaching a waterproof suit to the helmet and in the early 19th century became the standard diving dress.

Hazmat diving is underwater diving in a known hazardous materials environment. The environment may be contaminated by hazardous materials, the diving medium may be inherently a hazardous material, or the environment in which the diving medium is situated may include hazardous materials with a significant risk of exposure to these materials to members of the diving team. Special precautions, equipment and procedures are associated with hazmat diving so that the risk can be reduced to an acceptable level. These are based on preventing contact of the hazardous materials with the divers and other personnel, generally by encapsulating the affected personnel in personal protective equipment (PPE) appropriate to the hazard, and by effective decontamination after contact between the PPE and the hazardous materials.

Surface-supplied diving equipment (SSDE) is the equipment required for surface-supplied diving. The essential aspect of surface-supplied diving is that breathing gas is supplied from the surface, either from a specialised diving compressor, high-pressure gas storage cylinders, or both. In commercial and military surface-supplied diving, a backup source of surface-supplied breathing gas should always be present in case the primary supply fails. The diver may also wear a bailout cylinder which can provide self-contained breathing gas in an emergency. Thus, the surface-supplied diver is less likely to have an "out-of-air" emergency than a scuba diver using a single gas supply, as there are normally two alternative breathing gas sources available. Surface-supplied diving equipment usually includes communication capability with the surface, which improves the safety and efficiency of the working diver.

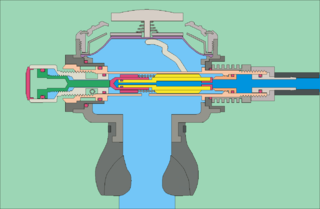

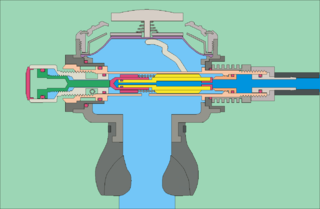

The mechanism of diving regulators is the arrangement of components and function of gas pressure regulators used in the systems which supply breathing gases for underwater diving. Both free-flow and demand regulators use mechanical feedback of the downstream pressure to control the opening of a valve which controls gas flow from the upstream, high-pressure side, to the downstream, low-pressure side of each stage. Flow capacity must be sufficient to allow the downstream pressure to be maintained at maximum demand, and sensitivity must be appropriate to deliver maximum required flow rate with a small variation in downstream pressure, and for a large variation in supply pressure, without instability of flow. Open circuit scuba regulators must also deliver against a variable ambient pressure. They must be robust and reliable, as they are life-support equipment which must function in the relatively hostile seawater environment, and the human interface must be comfortable over periods of several hours.