Dynamic positioning (DP) is a computer-controlled system to automatically maintain a vessel's position and heading by using its own propellers and thrusters. Position reference sensors, combined with wind sensors, motion sensors and gyrocompasses, provide information to the computer pertaining to the vessel's position and the magnitude and direction of environmental forces affecting its position. Examples of vessel types that employ DP include ships and semi-submersible mobile offshore drilling units (MODU), oceanographic research vessels, cable layer ships and cruise ships.

Surface-supplied diving is a mode of underwater diving using equipment supplied with breathing gas through a diver's umbilical from the surface, either from the shore or from a diving support vessel, sometimes indirectly via a diving bell. This is different from scuba diving, where the diver's breathing equipment is completely self-contained and there is no essential link to the surface. The primary advantages of conventional surface supplied diving are lower risk of drowning and considerably larger breathing gas supply than scuba, allowing longer working periods and safer decompression. Disadvantages are the absolute limitation on diver mobility imposed by the length of the umbilical, encumbrance by the umbilical, and high logistical and equipment costs compared with scuba. The disadvantages restrict use of this mode of diving to applications where the diver operates within a small area, which is common in commercial diving work.

Saturation diving is diving for periods long enough to bring all tissues into equilibrium with the partial pressures of the inert components of the breathing gas used. It is a diving mode that reduces the number of decompressions divers working at great depths must undergo by only decompressing divers once at the end of the diving operation, which may last days to weeks, having them remain under pressure for the whole period. A diver breathing pressurized gas accumulates dissolved inert gas used in the breathing mixture to dilute the oxygen to a non-toxic level in the tissues, which can cause potentially fatal decompression sickness if permitted to come out of solution within the body tissues; hence, returning to the surface safely requires lengthy decompression so that the inert gases can be eliminated via the lungs. Once the dissolved gases in a diver's tissues reach the saturation point, however, decompression time does not increase with further exposure, as no more inert gas is accumulated.

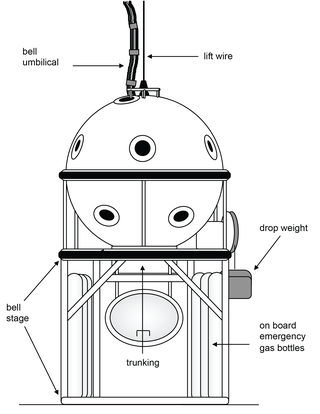

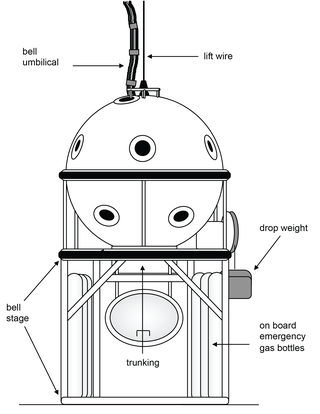

A diving bell is a rigid chamber used to transport divers from the surface to depth and back in open water, usually for the purpose of performing underwater work. The most common types are the open-bottomed wet bell and the closed bell, which can maintain an internal pressure greater than the external ambient. Diving bells are usually suspended by a cable, and lifted and lowered by a winch from a surface support platform. Unlike a submersible, the diving bell is not designed to move under the control of its occupants, or to operate independently of its launch and recovery system.

A diving support vessel is a ship that is used as a floating base for professional diving projects. Basic requirements are the ability to keep station accurately and reliably throughout a diving operation, often in close proximity to drilling or production platforms, for positioning to degrade slowly enough in deteriorating conditions to recover divers without excessive risk, and to carry the necessary support equipment for the mode of diving to be used.

Byford Dolphin was a semi-submersible, column-stabilised drilling rig operated by Dolphin Drilling, a subsidiarity of Fred Olsen Energy. Byford Dolphin was registered in Hamilton, Bermuda, and drilled seasonally for various companies in the British, Danish, and Norwegian sectors of the North Sea. In 2019, Dolphin scrapped the rig.

A diving chamber is a vessel for human occupation, which may have an entrance that can be sealed to hold an internal pressure significantly higher than ambient pressure, a pressurised gas system to control the internal pressure, and a supply of breathing gas for the occupants.

Diver rescue, usually following an accident, is the process of avoiding or limiting further exposure to diving hazards and bringing a diver to a place of safety. A safe place generally means a place where the diver cannot drown, such as a boat or dry land, where first aid can be administered and from which professional medical treatment can be sought. In the context of surface supplied diving, the place of safety for a diver with a decompression obligation is often the diving bell.

Commercial offshore diving, sometimes shortened to just offshore diving, generally refers to the branch of commercial diving, with divers working in support of the exploration and production sector of the oil and gas industry in places such as the Gulf of Mexico in the United States, the North Sea in the United Kingdom and Norway, and along the coast of Brazil. The work in this area of the industry includes maintenance of oil platforms and the building of underwater structures. In this context "offshore" implies that the diving work is done outside of national boundaries. Technically it also refers to any diving done in the international offshore waters outside of the territorial waters of a state, where national legislation does not apply. Most commercial offshore diving is in the Exclusive Economic Zone of a state, and much of it is outside the territorial waters. Offshore diving beyond the EEZ does also occur, and is often for scientific purposes.

An emergency ascent is an ascent to the surface by a diver in an emergency. More specifically, it refers to any of several procedures for reaching the surface in the event of an out-of-gas emergency, generally while scuba diving.

There are several categories of decompression equipment used to help divers decompress, which is the process required to allow divers to return to the surface safely after spending time underwater at higher ambient pressures.

The Thistle SALM was a tanker loading facility that allowed oil from the Thistle oilfield to be transported to land where a submarine export pipeline did not yet exist. It was also the site of the 8 August 1979 Wildrake diving accident that killed two divers. and the 21 January 1981 Stena Seaspread diving accident (non-fatal).

The Star Canopus diving accident was an incident in Scotland in November 1978 that killed two British commercial divers. During a routine dive beside the Beryl Alpha platform in the North Sea, the diving bell of the diving support vessel MS Star Canopus was lost when its main lift wire, life support umbilical, and guide wires were severed by an anchor chain of the semi-submersible Haakon Magnus. The bell dropped to the seabed at a depth of over 100 metres (330 ft). Its two occupants, 25-year-old Lothar Michael Ward and 28-year-old Gerard Anthony "Tony" Prangley, were unable to release the bell's drop weight in order to return to the surface because it was secured to the bell frame with secondary locking pins. Since there was not a bell stage to keep the bottom door of the bell off the seabed, the divers could not exit the bell to release the pins. Despite the efforts of three rescue vessels – Intersub 4, Tender Carrier, and Uncle John – the bell was not recovered for over thirteen hours, by which time Ward and Prangley had died of hypothermia and drowning.

The Drill Master diving accident was an incident in Norway in January 1974 that resulted in the death of two commercial divers. During a two-man dive from the North Sea rig Drill Master, the diving bell's drop weight was accidentally released, causing the bell to surface from a depth of 320 feet (98 m) with its bottom door open and drag the diver working outside through the water on his umbilical. The two divers, Per Skipnes and Robert John Smyth, both died from rapid decompression and drowning. The accident was caused by instructions aboard Drill Master which had not been updated when the bell system was modified and which stated that a valve should be closed during the dive which should have been open. Skipnes' body was never recovered.

The Stena Seaspread diving accident occurred on 21 January 1981, when a diving bell containing two divers had its umbilical cord severed. Both divers were rescued.

Bradley Westell was a British commercial diver who died in the North Sea off Bacton, Norfolk after his umbilical was dragged into one of the thrusters of the diving support vessel Stena Orelia. This indirectly led to the 1997 conviction of diving supervisor Kenneth Roberts for perverting the course of justice, and first prison sentence for a crime offshore working in the North Sea oil industry.

Surface supplied diving skills are the skills and procedures required for the safe operation and use of surface-supplied diving equipment. Besides these skills, which may be categorised as standard operating procedures, emergency procedures and rescue procedures, there are the actual working skills required to do the job, and the procedures for safe operation of the work equipment other than diving equipment that may be needed.

Diving procedures are standardised methods of doing things that are commonly useful while diving that are known to work effectively and acceptably safely. Due to the inherent risks of the environment and the necessity to operate the equipment correctly, both under normal conditions and during incidents where failure to respond appropriately and quickly can have fatal consequences, a set of standard procedures are used in preparation of the equipment, preparation to dive, during the dive if all goes according to plan, after the dive, and in the event of a reasonably foreseeable contingency. Standard procedures are not necessarily the only courses of action that produce a satisfactory outcome, but they are generally those procedures that experiment and experience show to work well and reliably in response to given circumstances. All formal diver training is based on the learning of standard skills and procedures, and in many cases the over-learning of the skills until the procedures can be performed without hesitation even when distracting circumstances exist. Where reasonably practicable, checklists may be used to ensure that preparatory and maintenance procedures are carried out in the correct sequence and that no steps are inadvertently omitted.

MS Wildrake/Holger Danske/NSS Felinto Perry was a motor diving vessel originally built and used by Norwegian Company. She was renamed Holger Dane after being sold to Denmark and finally NSS Felinto Perry (K-11) in the Brazilian Navy as a submarine relief ship from the Brazilian Navy. It was equipped to support diving, fire fighting and rescue of submarines.

Robert August Barth was a United States Navy Chief Quartermaster, pioneering aquanaut and professional diver. He was the only diver to participate in all U.S. Navy SEALAB missions led by George F. Bond. Barth is considered to be the father of the Rolex Sea Dweller. In 1967, he developed the idea for the helium release valve which was patented by Rolex on November 6, 1967.