The Occupational Safety and Health Administration (OSHA) is an agency of the United States Department of Labor. Congress established the agency under the Occupational Safety and Health Act, which President Richard M. Nixon signed into law on December 29, 1970. OSHA's mission is to "assure safe and healthy working conditions for working men and women by setting and enforcing standards and by providing training, outreach, education and assistance". The agency is also charged with enforcing a variety of whistleblower statutes and regulations. OSHA is currently headed by Acting Assistant Secretary of Labor Loren Sweatt. OSHA's workplace safety inspections have been shown to reduce injury rates and injury costs without adverse effects to employment, sales, credit ratings, or firm survival.

The Occupational Safety and Health Act of 1970 is a US labor law governing the federal law of occupational health and safety in the private sector and federal government in the United States. It was enacted by Congress in 1970 and was signed by President Richard Nixon on December 29, 1970. Its main goal is to ensure that employers provide employees with an environment free from recognized hazards, such as exposure to toxic chemicals, excessive noise levels, mechanical dangers, heat or cold stress, or unsanitary conditions. The Act created the Occupational Safety and Health Administration (OSHA) and the National Institute for Occupational Safety and Health (NIOSH).

Occupational noise is the amount of acoustic energy received by an employee's auditory system when they are working in the industry. Occupational noise, or industrial noise, is often a term used in occupational safety and health, as sustained exposure can cause permanent hearing damage.

Construction work is a hazardous land-based job. Some construction site jobs include: building houses, roads, tree forts, workplaces and repair and maintain infrastructures. This work includes many hazardous task and conditions such as working with height, excavation, noise, dust, power tools and equipment. The most common fatalities are caused by the fatal four: falls, being struck by an object, electrocutions, and being caught in between two objects. Construction work has been increasing in developing and undeveloped countries over the past few years. With an increase in this type of work occupational fatalities have increased. Occupational fatalities are individuals who die while on the job or performing work related tasks. Within the field of construction it is important to have safe construction sites.

A confined space is a space with limited entry and egress and not suitable for human inhabitants. An example is the interior of a storage tank, occasionally entered by maintenance workers but not intended for human occupancy. Hazards in a confined space often include harmful dust or gases, asphyxiation, submersion in liquids or free-flowing granular solids, electrocution, or entrapment.

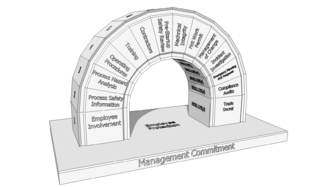

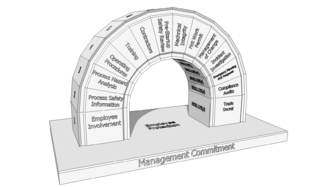

Process safety managementsystem is a regulation promulgated by the U.S. Occupational Safety and Health Administration (OSHA). A process is any activity or combination of activities including any use, storage, manufacturing, handling or the on-site movement of highly hazardous chemicals (HHCs) as defined by OSHA and the Environmental Protection Agency.

Hazardous Waste Operations and Emergency Response is a set of guidelines produced and maintained by the Occupational Safety and Health Administration which regulates hazardous waste operations and emergency services in the United States and its territories. With these guidelines, the U.S. government regulates hazardous wastes and dangerous goods from inception to disposal.

The Michigan Occupational Safety and Health Administration (MIOSHA) is a state government agency that regulates workplace safety and health in the U.S. state of Michigan. Michigan OSHA is an agency within the Michigan Department of Licensing and Regulatory Affairs and operates under a formal state-plan agreement with the Occupational Safety and Health Administration (OSHA).

The General Duty Clause of the United States Occupational Safety and Health Act states:

"Right to know", in the context of United States workplace and community environmental law, is the legal principle that the individual has the right to know the chemicals to which they may be exposed in their daily living. It is embodied in federal law in the United States as well as in local laws in several states. "Right to Know" laws take two forms: Community Right to Know and Workplace Right to Know. Each grants certain rights to those groups. The "right to know" concept is included in Rachel Carson's book Silent Spring.

Hearing conservation programs are designed to prevent hearing loss due to noise. Regarding occupational exposures to noise, a hearing conservation program is required by the Occupational Safety and Health Administration (OSHA) "whenever employee noise exposures equal or exceed an 8-hour time-weighted average sound level (TWA) of 85 decibels (dB) measured on the A scale or, equivalently, a dose of fifty percent." This 8-hour time-weighted average is known as an exposure action value. While the Mine Safety and Health Administration (MSHA) also requires a hearing conservation program, MSHA does not require a written hearing conservation program. MSHA's hearing conservation program requirement can be found in 30 CFR § 62.150, and is very similar to the OSHA hearing conservation program requirements. Therefore, only the OSHA standard 29 CFR 1910.95 will be discussed in detail.

An occupational fatality is a death that occurs while a person is at work or performing work related tasks. Occupational fatalities are also commonly called “occupational deaths” or “work-related deaths/fatalities” and can occur in any industry or occupation.

A physical hazard is an agent, factor or circumstance that can cause harm without contact. They can be classified as type of occupational hazard or environmental hazard. Physical hazards include ergonomic hazards, radiation, heat and cold stress, vibration hazards, and noise hazards. Engineering controls are often used to mitigate physical hazards.

A Dangerous restart occurs when power or energy is applied to a device whose "on / off" switch was in the "on" position when power was applied. In the United States the National Institute for Occupational Safety and Health (NIOSH) refers to this hazard as "The Uncontrolled Release of Mechanical, Electrical and Other Types of Hazardous Energy"

The Hazard Communication Standard requires employers in the United States to disclose toxic and hazardous substances in workplaces. This is related to the Worker Protection Standard.

Permit To Work (PTW) refers to management systems used to ensure that work is done safely and efficiently. These are used in hazardous industries and involve procedures to request, review, authorise, document and most importantly, de-conflict tasks to be carried out by front line workers. Permit to work is an essential part of control of work (COW), the integrated management of business critical maintenance processes. Control of work is made up of permit to work, hazard identification and risk assessment (RA), and isolation management (IM).

Machine guarding is a safety feature on or around manufacturing or other engineering equipment consisting of a shield or device covering hazardous areas of a machine to prevent contact with body parts or to control hazards like chips or sparks from exiting the machine. Machine guarding provides a means to protect humans from injury while working nearby or while operating equipment. It is often the first line of defense to protect operators from injury while working on or around industrial machinery during normal operations. In the U.S., machine guarding is referred to in OSHA's CFR 1910.212; in the U.K., machinery safety is covered mainly by PUWER."

There a number of 'occupational hazards of grain facilities. These hazards can be mitigated through diligence and following proper safety procedures. Grain Facility Occupation Exposure is the quantifiable expression of workplace health and safety hazards a grain handling facility employee is vulnerable to in performing his/her assigned duties. Exposure represents the probability that a given hazard will have some level of effect of a receptor of interest. This page utilizes data and information regarding grain facility occupational exposure in the United States.

Occupational heat stress is the net load to which a worker is exposed from the combined contributions of metabolic heat, environmental factors, and clothing worn which results in an increase in heat storage in the body. Heat stress can result in heat-related illnesses, such as heat stroke, hyperthermia, heat exhaustion, heat cramps or heat rashes. Although heat exhaustion is less severe, hyperthermia is a medical emergency and requires emergency treatment, which if not provided can even lead to death.

Hazardous energy in occupational safety and health is any source of energy that "can be hazardous to workers", such as from discharge of stored energy. Failure to control the unexpected release of energy can lead to machine-related injuries or fatalities. The risk from these sources of energy can be controlled in a number of ways, including access control procedures such as lockout-tagout.